A preparation method of silicon-carbon negative electrode material for lithium ion battery

A lithium-ion battery and negative electrode material technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as cycle performance attenuation, low conductivity, and low lithium intercalation potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

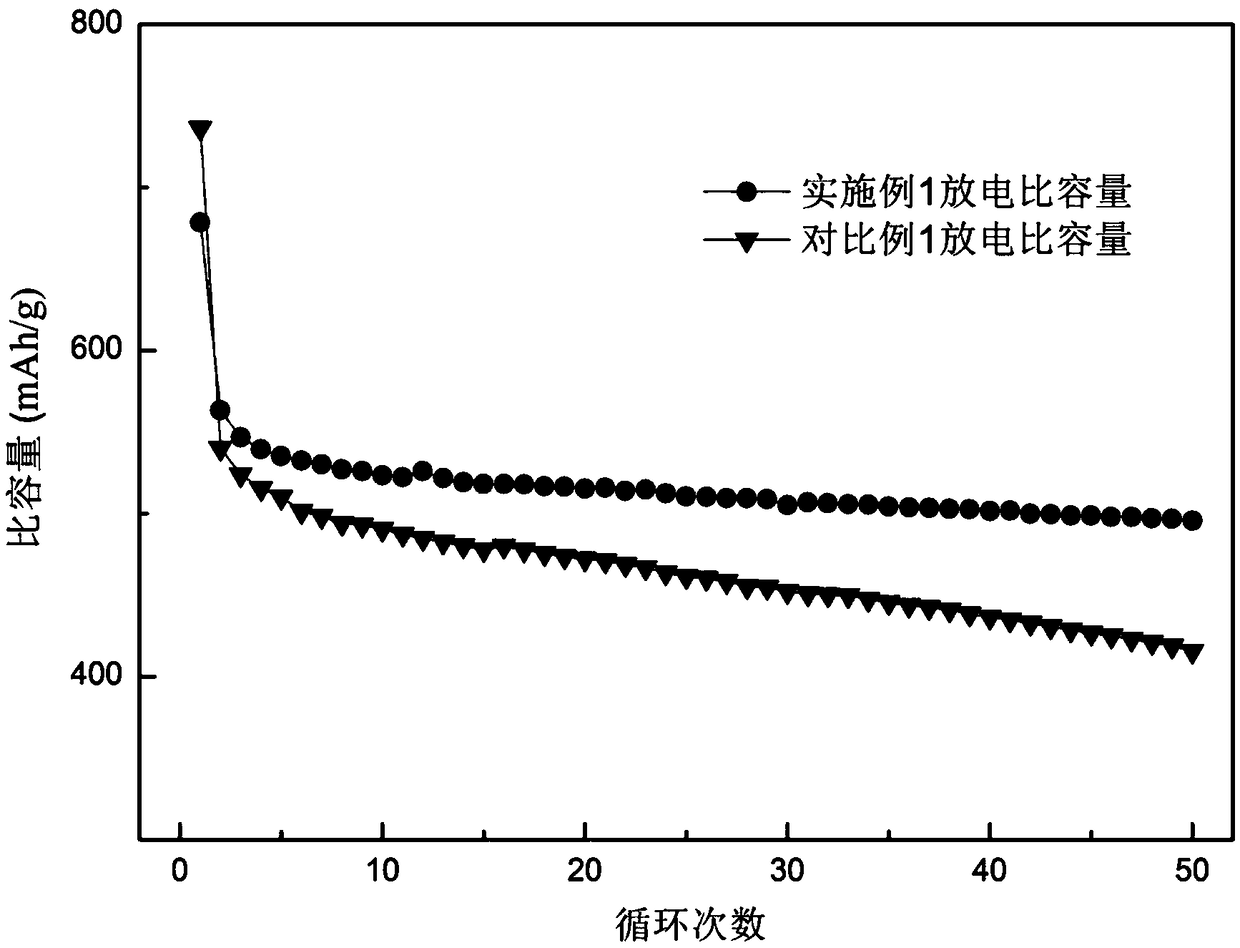

Embodiment 1

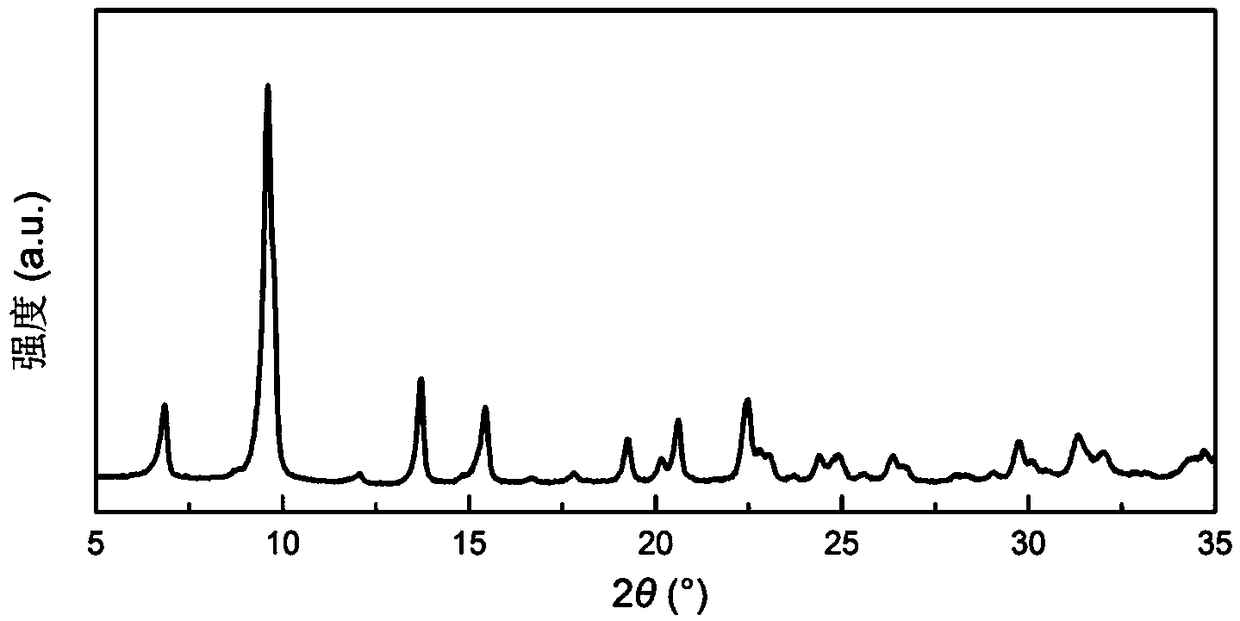

[0030] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, the specific preparation steps are as follows:

[0031] The first step, 1g mean particle diameter is the nano Si powder of 100nm, 0.03g hexadecyl trimethylammonium bromide, 23.8g Zn(NO 3 ) 2 ·6H 2 O, 6.6g H 2 BDC and 1g of CNTs were added to 800mL of DMF, and ultrasonically stirred at 40KHz for 15min to form a uniformly dispersed nano-Si / CNTs suspension;

[0032] In the second step, 32g of TEA was added dropwise to the suspension at a constant speed. After sufficient reaction, the precipitate was washed and filtered with DMF three times, and then placed in a vacuum oven at 150°C for 18 hours to obtain the precursor complex;

[0033] In the third step, the obtained precursor is placed in a tube furnace with an argon atmosphere, the flow rate of the argon gas is 60mL / min, heated to 900°C at a heating rate of 5°C / min and kept for 3 hours, then cooled to room temperature with t...

Embodiment 2

[0036] A method for preparing a silicon-carbon negative electrode material for a lithium-ion battery, the specific preparation steps are as follows:

[0037] The first step, 1g average particle diameter is the nano silicon powder of 150nm, 0.04g polyvinylpyrrolidone, 11.9g Zn(NO 3 ) 2 ·6H 2 O, 3.3 g H 2 BDC and 1g of CNTs were added to 400mL of DMF, and ultrasonically stirred at an ultrasonic frequency of 30KHz for 20min to form a uniformly dispersed nano-Si / CNTs suspension;

[0038] In the second step, 16g of TEA was added dropwise to the suspension at a constant speed. After sufficient reaction, the precipitate was washed and filtered with DMF four times, and then placed in a vacuum oven at 140°C for 24 hours to obtain the precursor complex;

[0039] The third step is to place the obtained precursor in a tube furnace with a nitrogen atmosphere. The flow rate of nitrogen gas is 50mL / min. After heating to 950°C at a heating rate of 10°C / min and keeping it for 2 hours, it is...

Embodiment 3

[0042] The first step, 1g average particle diameter is the nano-Si powder of 200nm, 0.02g p-ethylbenzoic acid, 35.7g Zn(NO 3 ) 2 ·6H 2 O, 9.9 g H 2 BDC and 1g of CNTs were added to 1200mL of DMF, and ultrasonically stirred at 50KHz for 10min to form a uniformly dispersed nano-Si / CNTs suspension;

[0043] In the second step, 48g of TEA was added dropwise to the suspension at a constant speed. After sufficient reaction, the precipitate was washed and filtered with DMF three times, and then placed in a vacuum oven at 160°C for 14 hours to obtain the precursor complex;

[0044] In the third step, the obtained precursor is placed in a tube furnace with a nitrogen atmosphere, the nitrogen gas flow rate is 80mL / min, heated to 850°C at a heating rate of 2°C / min and kept for 4 hours, then cooled to room temperature with the furnace to obtain silicon carbon composite materials;

[0045] The fourth step is to uniformly mix the silicon-carbon composite material accounting for 40% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com