Silicon oxide composite negative electrode material for lithium ion battery and preparation method of silicon oxide composite negative electrode material

A lithium-ion battery and silicon oxide technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problem of affecting the service life of silicon-oxygen materials, the inability to remove silicate impurities, and the large loss of capacity of prepared materials, etc. problem, to achieve the effect of improving reversible capacity and efficiency, improving the first specific capacity, and low oxygen value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the lithium-ion battery silicon oxide composite negative electrode material of the present embodiment specifically includes:

[0035] S1: Silicon oxide with a median particle size (D50) of 0.5-2.5 μm, aluminum metal powder with a median particle size (D50) of 5-30 μm, and CaCl with a median particle size (D50) of 50-200 μm 2 -AlCl 3 Mix molten salt to carry out VC mixing work, the mixing speed is 900rpm, and the mixing time is 2h, wherein the added molar ratio of silicon oxide and aluminum metal powder material is 1:0.2, and the added mass ratio of silicon oxide and mixed molten salt is 1: 3. Mixed molten salt CaCl 2 -AlCl 3 The mass ratio between them is 6:4.

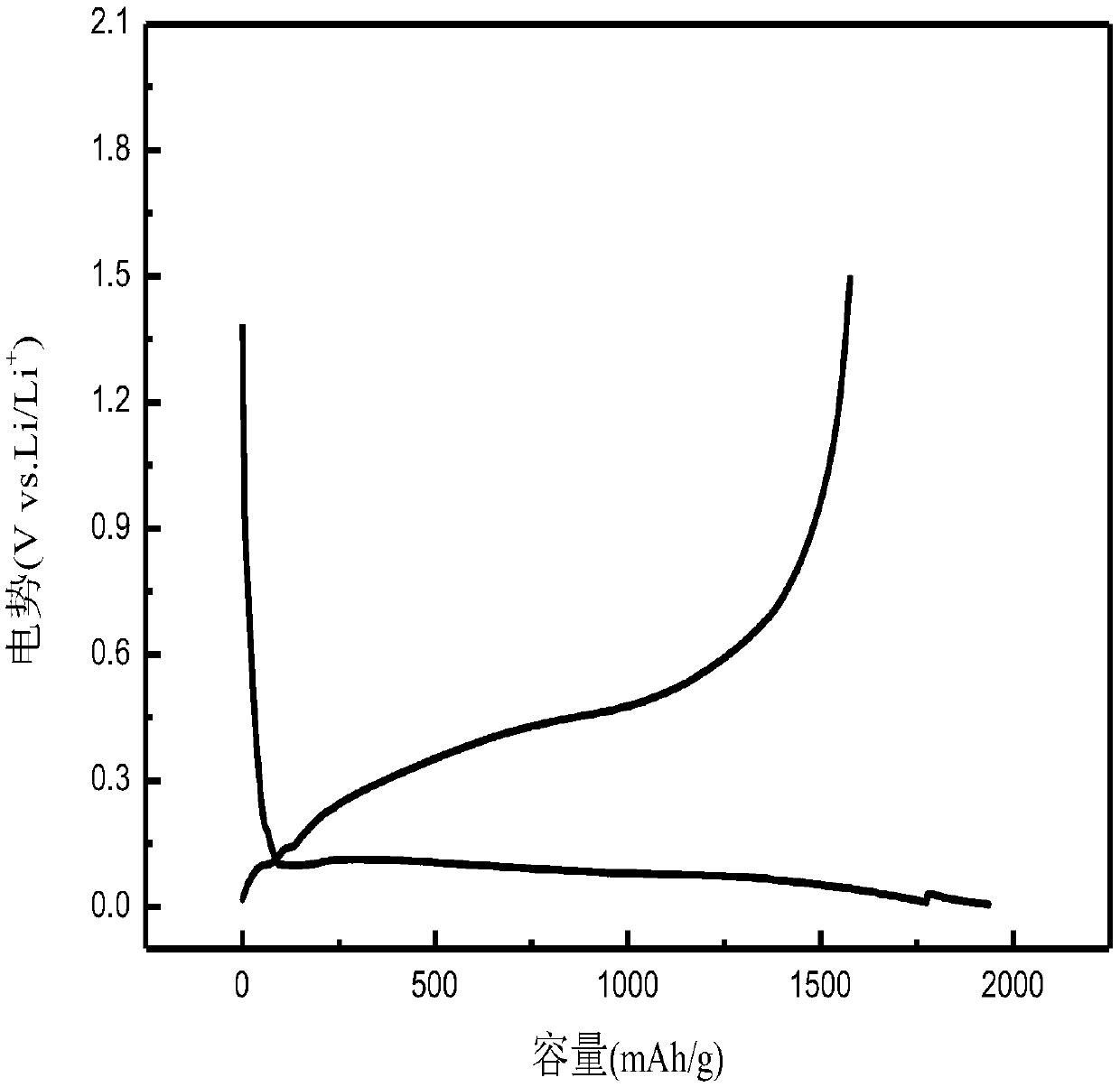

[0036] S2: Put the mixed material in a box furnace for roasting, under the protection of nitrogen atmosphere, the roasting temperature is 500°C, the heating rate is 3°C / min, keep warm for 2h, and take out the material after cooling. Add the obtained material to 2mol / L hydrochloric a...

Embodiment 2

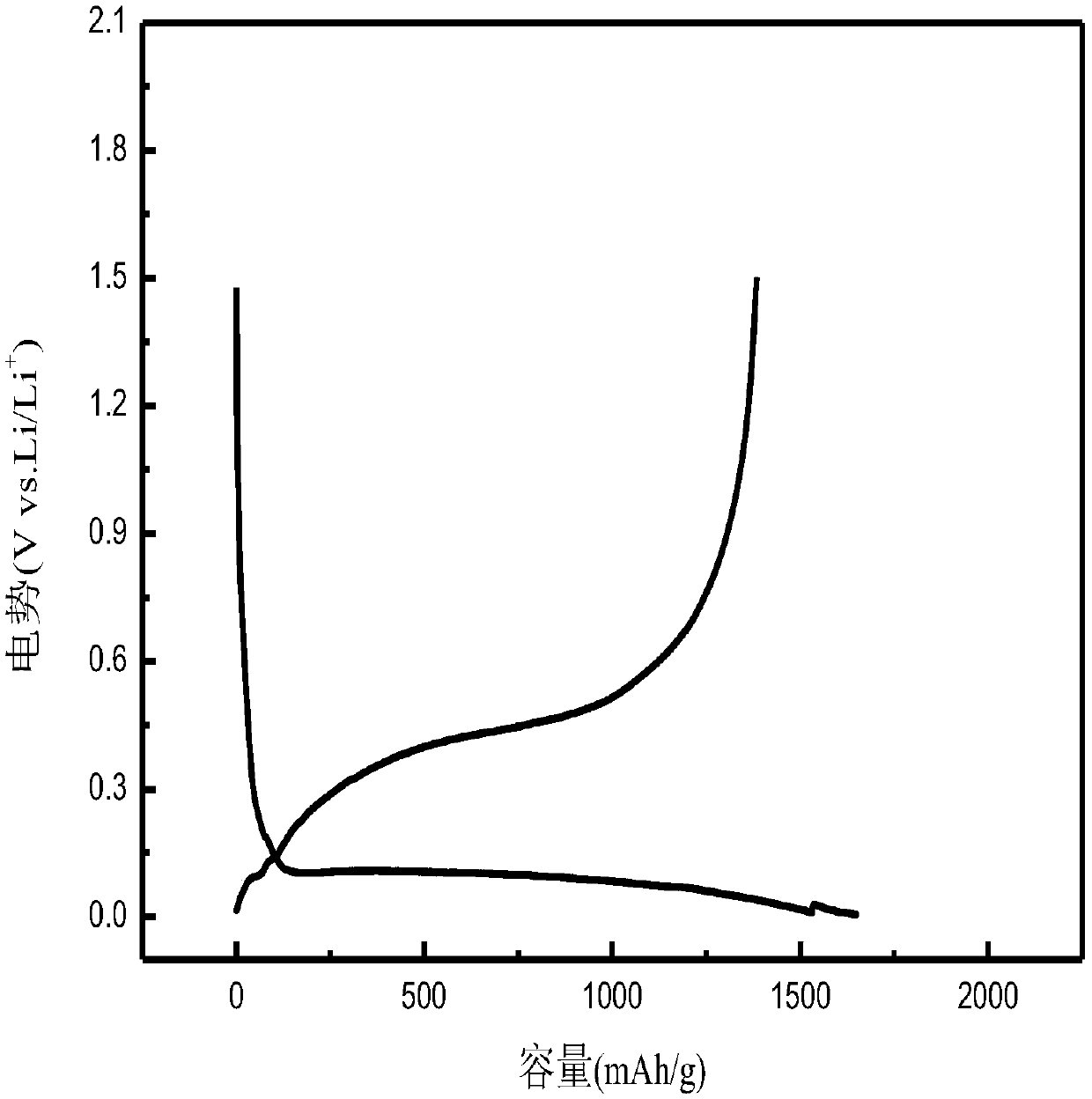

[0039] The preparation method of the lithium-ion battery silicon oxide composite negative electrode material in this embodiment specifically includes: silicon oxide with a median particle size (D50) of 4-8 μm, and silicon oxide with a median particle size (D50) of 80-120 μm Aluminum metal powder, 50-200μm MgCl 2 - KCl mixed molten salt for VC mixing work, the mixing speed is 800rpm, and the mixing time is 2h, wherein the molar ratio of silicon oxide and aluminum metal powder is 1:0.8, and the mass ratio of silicon oxide and mixed molten salt is 1:8, mixed molten salt MgCl 2 The mass ratio between -KCl is 2:8. Put the mixed material into a box furnace for roasting under the protection of argon atmosphere, the roasting temperature is 750°C, the heating rate is 10°C / min, keep it warm for 8h, and take out the material after cooling. Add the obtained material to 3mol / L hydrochloric acid and mix and stir. The mass ratio of the obtained material to hydrochloric acid is 1:6, the sti...

Embodiment 3

[0041] The preparation method of the lithium-ion battery silicon oxide composite negative electrode material of the present embodiment specifically includes:

[0042] Silicon oxide with a median particle size (D50) of 0.5-2.5 μm, zinc metal powder with a median particle size (D50) of 5-30 μm, and KCl-AlCl with a median particle size (D50) of 50-200 μm 3 Mix the molten salt to carry out VC mixing work, the mixing speed is 1500rpm, and the mixing time is 2h, wherein the added molar ratio of silicon oxide and zinc metal powder material is 1:0.2, and the added mass ratio of silicon oxide and mixed molten salt is 1: 3. Mixed molten salt KCl-AlCl 3 The mass ratio between them is 3.5:6.5. Put the mixed material into a box furnace for roasting under the protection of argon atmosphere, the roasting temperature is 300°C, the heating rate is 3°C / min, keep it warm for 2h, and take out the material after cooling. Add the obtained material to 2mol / L hydrochloric acid and mix and stir. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com