Pre-lithiated silicon monoxide/carbon composite material, and preparation method and application thereof

A carbon composite material and silicon oxide technology, which is applied in electrochemical generators, active material electrodes, electrical components, etc., can solve the problem that the degree and uniformity of pre-lithiation are difficult to control, and are not suitable for large-scale industrial production and preparation technology. complex problems, to achieve the effect of improving electrochemical performance, facilitating production operations, and uniform carbon layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

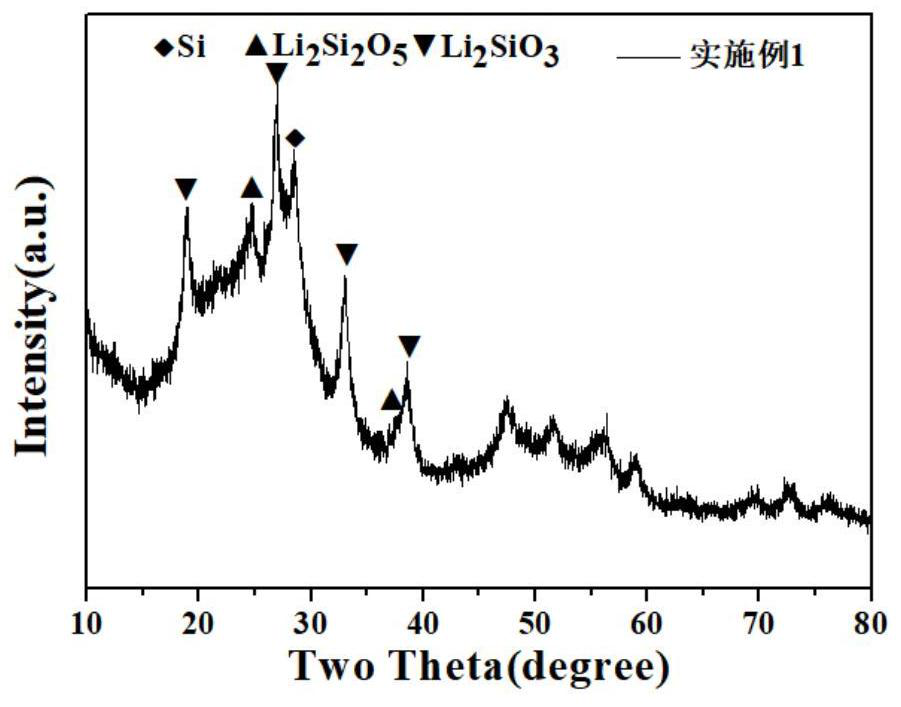

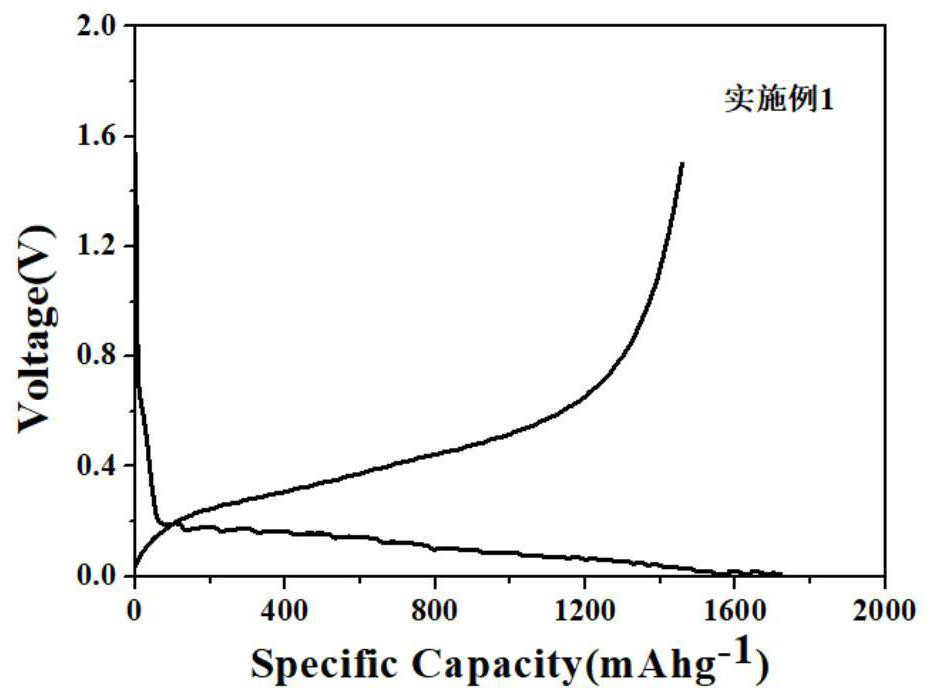

Embodiment 1

[0035] A preparation and application of a pre-lithiated silicon oxide / carbon composite material, comprising the following steps:

[0036] 1) Weigh 2 kg of 5-micron silicon oxide and place it in a rotary kiln, raise the temperature to 800°C, feed acetylene gas at a flow rate of 100 L / h, and heat-preserve for 2 hours to obtain a silicon oxide / carbon composite material.

[0037] 2) Pulverize and sieve the lithium hydride. The median particle size after pulverization is 2 microns. 200g of the pulverized lithium hydride and 1800g of silicon oxide / carbon composite material are mixed with VC, and mixed uniformly to obtain a calcined material.

[0038] 3) Put the pre-fired material obtained in step 2 in the kiln, feed the mixed gas of hydrogen (100L / h) / argon (50L / h), raise the temperature to 650°C at 5°C / min, and keep it warm for 5h to obtain the pre-calcined Lithiated silicon oxide composites.

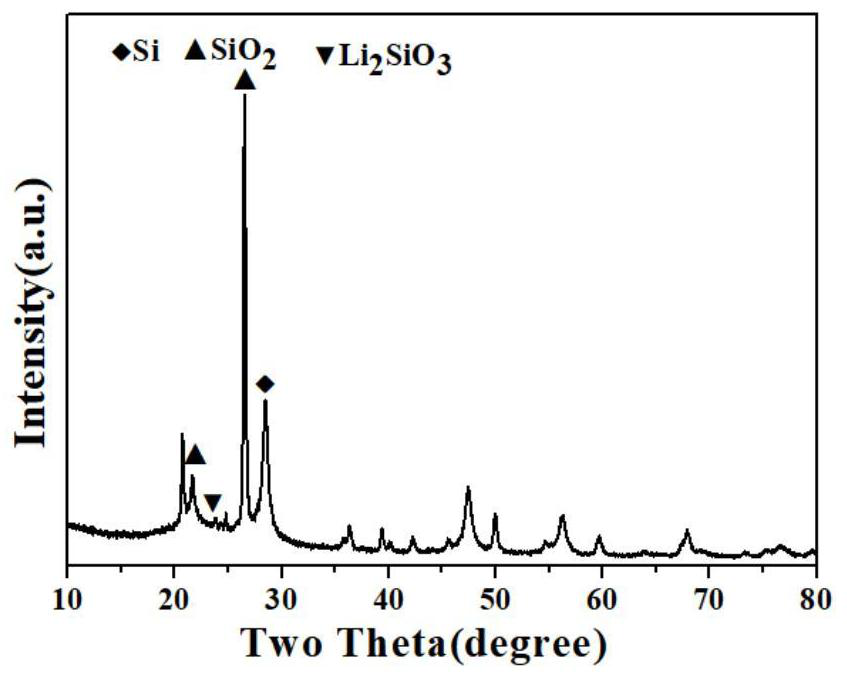

Embodiment 2

[0040] A preparation and application of a pre-lithiated silicon oxide / carbon composite material, comprising the following steps:

[0041] 1) Weigh 2 kg of 5-micron silicon dioxide and place it in a rotary kiln, raise the temperature to 800 ° C, feed acetylene gas at a flow rate of 200 L / h, and heat-preserve for 2 hours to obtain a silicon oxide / carbon composite material.

[0042] 2) Crushing and sieving lithium hydride, the median particle size of which is 2 microns after pulverization, VC mixing of 200 g of pulverized lithium hydroxide and 1500 g of silicon oxide / carbon composite material, and mixing uniformly to obtain a calcined material.

[0043]3) Put the pre-fired material obtained in the second step in the kiln, feed the mixed gas of hydrogen (50L / h) / argon (50L / h), raise the temperature to 650°C at 5°C / min, keep it for 5h, and obtain the pre-calcined Lithiated silicon oxide composite.

Embodiment 3

[0045] A preparation and application of a pre-lithiated silicon oxide / carbon composite material, comprising the following steps:

[0046] 1) Weigh 2kg of 5 micron silicon oxide and place it in a rotary kiln, raise the temperature to 900°C, feed acetylene gas at a flow rate of 200L / h, and heat-preserve for 2 hours to obtain a silicon oxide / carbon composite material.

[0047] 2) Pulverize and sieve the lithium hydride. The median particle size after pulverization is 2 microns. 200 g of the pulverized lithium hydride and 400 g of silicon oxide / carbon composite material are mixed with VC, and mixed uniformly to obtain a calcined material.

[0048] 3) Put the pre-fired material obtained in the second step in the kiln, feed the mixed gas of hydrogen (50L / h) / argon (50L / h), raise the temperature to 700°C at 5°C / min, keep it for 5h, and obtain the pre-calcined Lithiated silicon oxide composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com