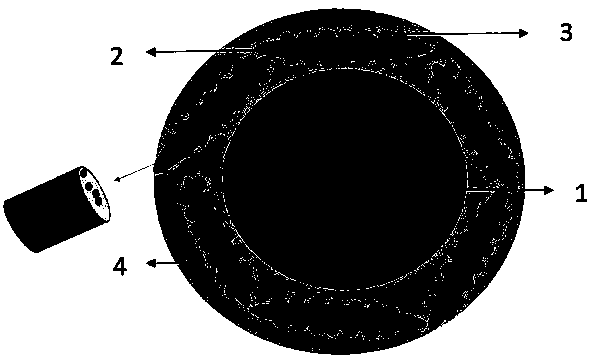

Silicon carbon composite negative electrode material and preparation method thereof

A silicon-carbon composite and negative electrode material technology, applied in the direction of battery electrodes, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of limiting material cycle performance, reserving buffer space, etc., the process is simple and fast, and prevents electrical contact loss , Improve the effect of mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

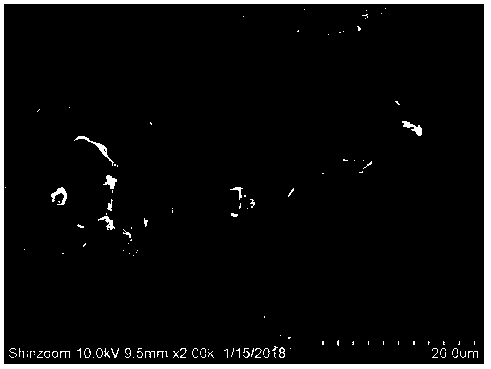

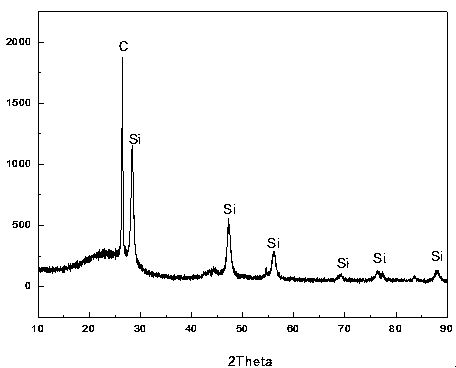

[0040] Use high-purity nitrogen to repeatedly purge the reaction furnace and vacuumize to ensure the safety of the system. Flow high-purity silane gas (99.99%) at a low flow rate of 2.0 L / min and keep it constant to heat the silane at 950°C. Decomposition, after 20 minutes using high-purity acetylene (C 2 h 2 ) gas into the same furnace, carbon coating was carried out at 950 °C at a flow rate of 2.0 L / min for 6 min, and finally the system was naturally cooled to room temperature under the protection of nitrogen, and the furnace powder S1 was collected.

[0041] Take S1 and add it to the DMF solution of polyacrylonitrile with a mass fraction of 3.40% (the mass ratio of S1 to the solution is 1:5), and use electrospinning technology (electrospinning is a polymer solution or a solution formed by the action of an electrostatic field) The process, when the electric field force of the charged polymer solution overcomes the surface tension, and when it is extruded from the spinneret,...

Embodiment 2

[0045] The reaction furnace was purged repeatedly with high-purity nitrogen and vacuumed to ensure the safety of the system. High-purity silane gas (99.99%) flowed at a low flow rate of 1.0 L / min and kept constant. Use silane to heat at 750°C. Decomposition, after 20 minutes using high-purity acetylene (C 2 h 2 ) gas in the same furnace at 750 °C for 10 min at a flow rate of 2.0 L· / min, and finally the system was naturally cooled to room temperature under the protection of nitrogen, and the furnace powder S1 was collected.

[0046] Take S1 and add it to 4.50% polyacrylonitrile DMF solution (the mass ratio of S1 to solution is 1:11), and electrospin the mixed solution in an electric field with an electric field strength of 75KV / m using electrospinning technology. The obtained polyacrylonitrile fiber membrane of silicon nanoparticles was dried under vacuum condition at 80° C. to remove the solvent. Then put it in a tube furnace for pre-oxidation (room temperature, 5°C / min, hea...

Embodiment 3

[0050] The experimental system was repeatedly purged and vacuumed with high-purity nitrogen to ensure the safety of the system. High-purity silane gas (99.99%) flowed at a low flow rate of 1.5 L / min and kept constant. Use silane to heat at 800 °C. Decomposition, after 20 minutes using high-purity acetylene (C 2 h 2 ) gas in the same furnace at 800 °C with a flow rate of 2.0 L / min for 7 min, and finally the system was naturally cooled to room temperature under the protection of nitrogen, and the furnace powder S1 was collected.

[0051] Take S1 and add it to a 3.40% polyacrylonitrile dimethylformamide (DMF) solution (the mass ratio of S1 to the solution is 1:9), and use electrospinning technology to mix the solution in an electric field with an electric field strength of 55KV / m Perform electrospinning. The obtained polyacrylonitrile fiber membrane of silicon nanoparticles was dried under vacuum condition at 60° C. to remove the solvent. Then put it in a tube furnace for pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com