Fast charge graphite negative electrode material and preparation method thereof

A graphite anode, graphite technology, applied in the preparation/purification of carbon, chemical instruments and methods, battery electrodes, etc., can solve the problems of low initial efficiency, poor cycle performance, and many structural defects of materials, and achieve excellent cycle performance, high Magnification, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

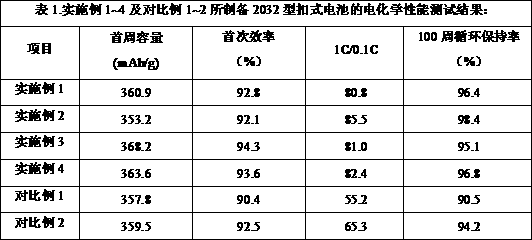

Embodiment 1

[0028] Add 4 kg of needle coke (D50 is 7.0 μm) and 1 kg of phenolic resin (D50 is 5.0 μm) alternately into the double-helix conical mixer and mix for 2 hours, then transfer to a medium temperature treatment furnace and heat to 500 °C under nitrogen protection Heat treatment for 4 hours, naturally cool to room temperature, and then conduct graphitization treatment at 3000°C for 36 hours. After mixing and screening, the fast-charging graphite negative electrode material is prepared.

Embodiment 2

[0030] Add 4.5kg of petroleum coke (D50 is 5.0μm) and starch (D50 is 15.0μm) 0.5kg alternately into the double-helix conical mixer and mix for 2 hours, then transfer to a medium temperature treatment furnace and heat to 600°C under nitrogen protection Heat treatment for 3 hours, naturally cool to room temperature, and then conduct graphitization treatment at 2800°C for 48 hours. After mixing and screening, the fast-charging graphite negative electrode material is prepared.

Embodiment 3

[0032] Add 4.5kg of spherical natural graphite (D50 is 8.0μm) and 2kg of glucose (25% aqueous solution) into the liquid phase coating machine and mix for 2 hours, then spray dry, and transfer the dried powder to a medium temperature treatment furnace, and under the protection of nitrogen Heating to 550°C for 5h heat treatment, cooling to room temperature naturally, and then performing graphitization treatment at 2900°C for 48h, mixing and sieving to obtain a fast-charging graphite negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com