Preparation method of caky-structure nano zinc oxide material

A nano-zinc oxide, cake-like technology, applied in the field of preparation of zinc oxide materials, can solve the problems of unfavorable zinc oxide charge and discharge rate and electrode stability, unfavorable lithium ion intercalation and deintercalation, and long electron path, so as to reduce the electron space The effect of high hole recombination rate, low requirement for reaction equipment and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

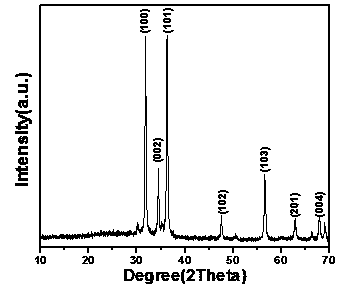

[0011] A method for preparing nano-zinc oxide material with a cake-like structure, and proceed as follows: 1. Prepare a hexamethylene tetramine (HMT) aqueous solution of 0.1 mol / L of zinc nitrate with an equimolar ratio in the solution Add the surfactant compounded with alkylammonium bromide and Tween 80, the molar ratio of the two is 1:1, and the molar concentration of alkylammonium bromide is 1 mmol / L; 2. Use nitric acid to adjust the pH of the solution to 6.5; 3. The solution is placed in the reactor, the reactor is lined with polytetrafluoroethylene, and the glass electrode coated with ITO (ITO is indium tin oxide, a transparent conductive film) is added while the solution is added to the reactor, so that the zinc oxide is on the electrode 4. Keep the reaction kettle at 96°C in a constant temperature box and react for 3 hours; 5. Anneal the obtained electrode with zinc oxide in a sintering furnace at 400°C for 2 hours to obtain a special assembly shape Electrode or powder o...

Embodiment 2

[0013] A method for preparing nano-zinc oxide material with a cake-like structure, and proceed as follows: 1. Prepare a hexamethine tetraethyl (HMT) aqueous solution of zinc nitrate with an equimolar ratio of 0.05 mol / L in the solution Add the surfactant compounded with cationic and nonionic surfactants, the molar ratio of the two is 2:1, the molar concentration of the cationic surfactant is 0.01mmol / L; 2. Use nitric acid to adjust the pH of the solution to 5; 3. , Put the solution in the reactor, the reactor is lined with polytetrafluoroethylene, keep at 80℃ in a constant temperature device, and the reaction will proceed for 2 hours; 4. While the solution is added to the reactor, place the ITO glass electrode where zinc oxide needs to be deposited. The zinc oxide is grown on the electrode, washed and dried to obtain a powder; 5. The obtained electrode with zinc oxide or powder zinc oxide is annealed in a sintering furnace at 150° C. for 1 hour.

Embodiment 3

[0015] The difference between this embodiment and embodiment 1 is that the concentration of zinc nitrate and HMT in step 1 is 0.1 mol / L; in step 4, no electrode is added, and the precipitated zinc oxide is directly washed and dried to obtain the powder directly. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com