A kind of tantalum disulfide/titanium dioxide composite material and its preparation method and application

A composite material and electrostatic combination technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., to achieve the effect of less energy consumption and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] TiO 2 Preparation of Particle Dispersions. TiO 2 The particles were dispersed in deionized water to obtain TiO 2 particle dispersion, and use an acidic solution to adjust the pH to 2-5, preferably 3-4, to make the surface positively charged. Among them, TiO 2 The concentration of the particle dispersion is 4-10 mg / ml, preferably 7 mg / ml. The acidic solution can be hydrochloric acid or sulfuric acid.

[0054] TaS adjusted to pH 2-5 2 Add (drop in) an appropriate amount of positively charged TiO with a pH of 2 to 5 into the nanosheet dispersion 2 Particle dispersion, and then under continuous stirring, mix the two evenly, and fully and continuously stir for 20 minutes to obtain a suspension. Among them, the control TaS 2 Nanosheets and TiO 2 The mass ratio of the composite material is (0.005-0.1):1, preferably (0.01-0.04):1. The rate of dripping can be 3~6ml / min, do not add too fast, otherwise TiO 2 Particles are not uniformly dispersed in TaS 2 nanosheet surf...

Embodiment 1

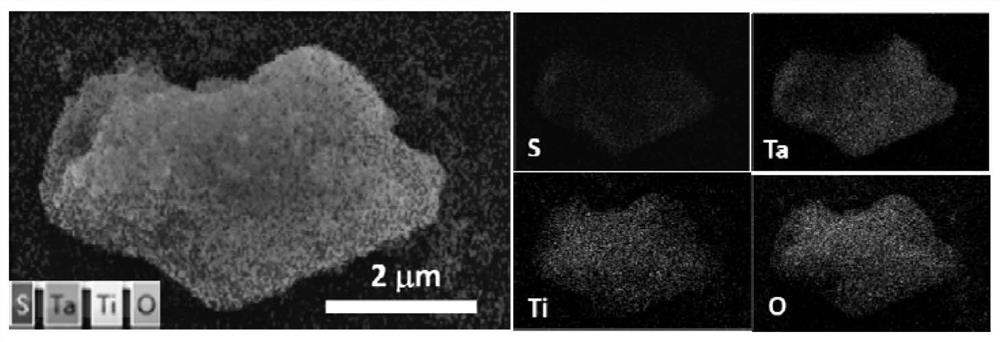

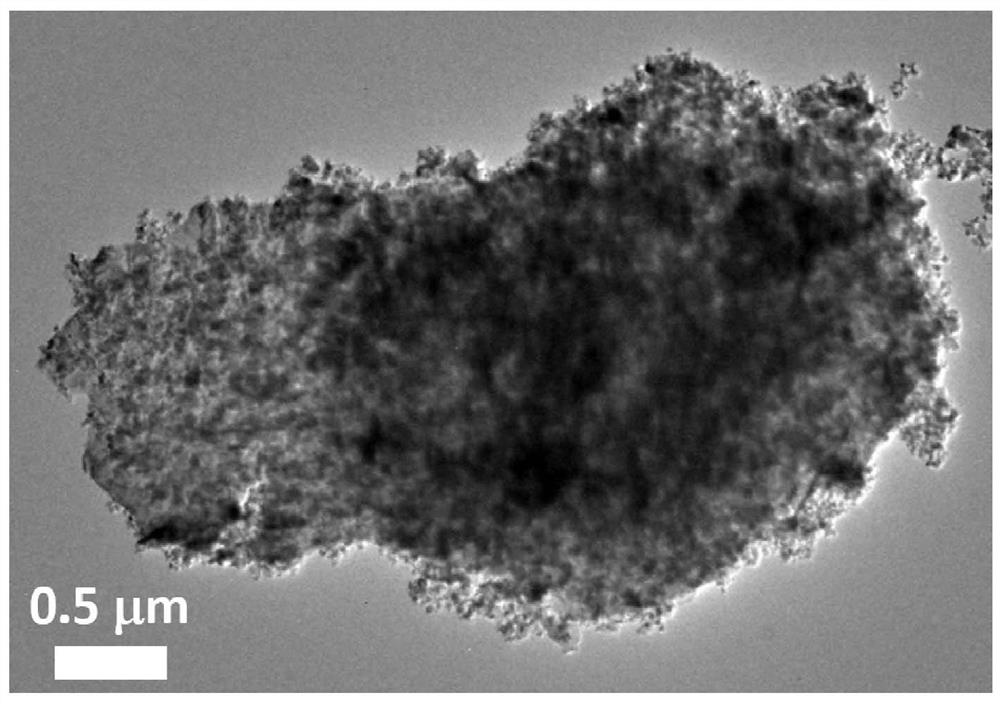

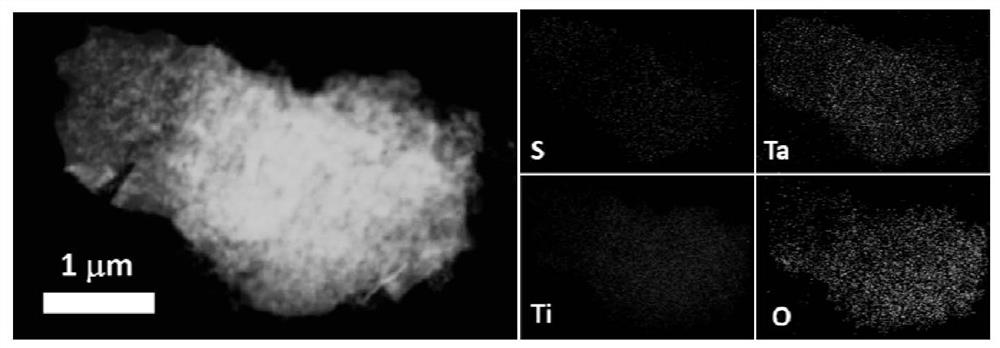

[0063] 1.75 mg of TaS 2 The nanosheets were dispersed in 50ml deionized water for 30 minutes by ultrasonic dispersion to obtain uniform, stable and well-dispersed TaS 2 nanosheet dispersion, and then adjust its pH to about 3 with dilute hydrochloric acid. Similarly, disperse 0.35g of P25 in 50ml of deionized water for ultrasonic dispersion for 30 minutes to obtain uniform, stable and well-dispersed P25 nanoparticles, and then adjust its pH to about 3 with dilute hydrochloric acid. Under the action of magnetic stirring, the P25 nanoparticle dispersion was added dropwise to TaS at a rate of 3-6ml / min. 2 In the nanosheet dispersion, stir for 20 minutes, perform suction filtration, wash three times with deionized water and absolute ethanol, and then place in an oven at 50°C for drying to obtain TaS with uniform and stable morphology 2 / TiO 2 Composite material powder, where TaS 2 The weight ratio of nanosheets is 0.5%. see figure 2 , when the pH is around 3, TaS 2 The surf...

Embodiment 2

[0067] 3.5mg of TaS 2 The nanosheets were dispersed in 50ml deionized water for 30 minutes by ultrasonic dispersion to obtain uniform, stable and well-dispersed TaS 2 nanosheet dispersion, and then adjust its pH to about 3 with dilute hydrochloric acid. Similarly, disperse 0.35g of P25 in 50ml of deionized water for ultrasonic dispersion for 30 minutes to obtain uniform, stable and well-dispersed P25 nanoparticles, and then adjust its pH to about 3 with dilute hydrochloric acid. Under the action of magnetic stirring, the P25 nanoparticle dispersion was added dropwise to TaS at a rate of 3-6ml / min. 2 In the nanosheet dispersion, stir for 20 minutes, perform suction filtration, wash three times with deionized water and absolute ethanol, and then place in an oven at 50°C for drying to obtain TaS 2 / TiO 2 Composite material powder, where TaS 2 The weight ratio of the nanosheets was 1%. see figure 2 , when the pH is around 3, TaS 2 The surface carries a negative charge, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com