Preparation method for modified graphene and application of modified graphene to positive materials for lithium batteries

A graphene and modification technology, applied in the direction of active material electrodes, positive electrodes, battery electrodes, etc., can solve the problems of easy agglomeration of graphene, deterioration of graphene dispersion performance, increase of graphene layer thickness, etc., and achieve good dispersion. , The effect of increasing the electric capacity and charging and discharging rate, and adding less amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

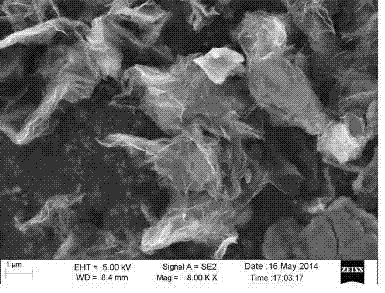

[0031] Preparation of modified graphene:

[0032] (1) Graphene oxide slurry is obtained by reacting natural flake graphite with strong oxidant potassium permanganate and 98% concentrated sulfuric acid;

[0033] (2) Weigh the graphene oxide slurry prepared above, wash with distilled water until neutral and dry;

[0034] (3) Reduce the dried graphene oxide at 400°C under the protection of nitrogen to obtain graphene;

[0035] (4) Ultrasound the graphene in hydrogen peroxide solution with 30% oxidant for 2 hours, the proportion of graphene and hydrogen peroxide solution is 1g / L, take it out, wash and dry it;

[0036] (5) Prepare cetyltrimethylammonium bromide with a concentration of 0.5mg / mL;

[0037] (6) Add graphene to cetyltrimethylammonium bromide solution according to the mass ratio of graphene and cetyltrimethylammonium bromide as 1:5, after ultrasonication, suction filtration, vacuum at 60°C drying to obtain the sample;

[0038] (7) Measure its powder resistivity to be...

Embodiment 2

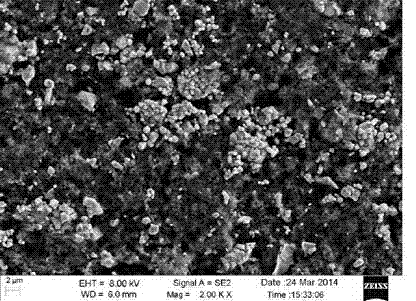

[0041] Preparation of modified graphene:

[0042] (1) Graphene oxide slurry is obtained by reacting natural flake graphite with strong oxidant potassium permanganate and 98% concentrated sulfuric acid;

[0043] (2) Weigh the graphene oxide slurry prepared above, wash with distilled water until neutral and dry;

[0044] (3) Reduce the dried graphene oxide at 600°C under the protection of nitrogen to obtain graphene;

[0045] (4) Ultrasound the graphene in hydrogen peroxide solution with 30% oxidant for 3 hours, the proportion of graphene and hydrogen peroxide solution is 3g / L, take it out, wash and dry it;

[0046] (5) Prepare octadecyltrimethylammonium chloride with a concentration of 0.5mg / mL;

[0047] (6) Add graphene to octadecyltrimethylammonium chloride solution according to the mass ratio of graphene and octadecyltrimethylammonium chloride of 2:5, after ultrasonication, suction filtration, vacuum at 60°C drying to obtain the sample;

[0048] (7) Measure its powder re...

Embodiment 3

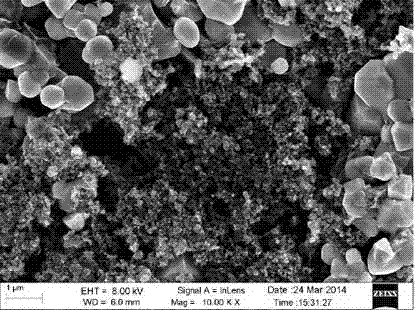

[0051] Preparation of modified graphene:

[0052] (1) Graphene oxide slurry is obtained by reacting natural flake graphite with strong oxidant potassium permanganate and 98% concentrated sulfuric acid;

[0053] (2) Weigh the graphene oxide slurry prepared above, wash with distilled water until neutral and dry;

[0054] (3) Reduce the dried graphene oxide at 800°C under the protection of nitrogen to obtain graphene;

[0055] (4) Ultrasound the graphene in oxidant 10% nitric acid solution for 4 hours, the proportion of graphene and nitric acid solution is 8g / L, take it out, wash and dry;

[0056] (5) Prepare tetradecyltrimethylammonium chloride with a concentration of 0.5mg / mL;

[0057] (6) Add graphene to tetradecyltrimethylammonium chloride solution according to the mass ratio of graphene and tetradecyltrimethylammonium chloride at 2:1, after ultrasonication, suction filtration, vacuum at 60°C drying to obtain the sample;

[0058] (7) Measure its powder resistivity to be 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com