3D foil material, preparation method and application of positive plate and negative plate containing same

A positive electrode sheet and foil technology, which is applied in the field of positive and negative electrode sheet preparation, can solve the problems of affecting battery capacity, limiting slurry coating thickness and coating amount, affecting battery rate and cycle performance, etc., so as to improve cycle performance , The effect of shortening the electron transmission distance and increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

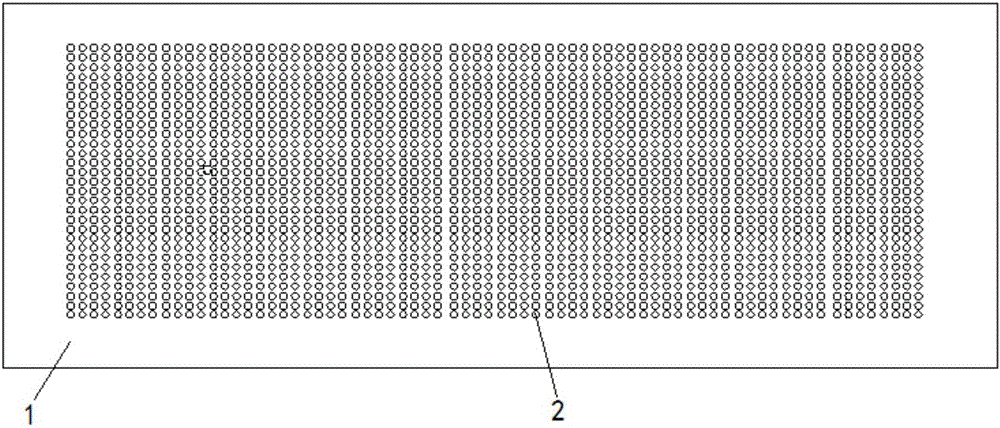

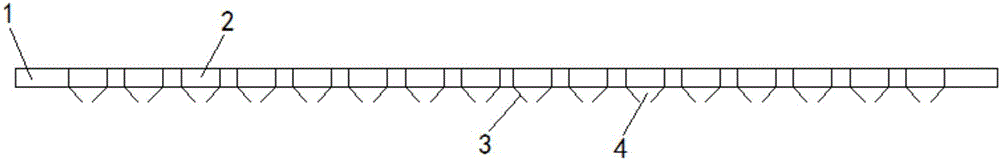

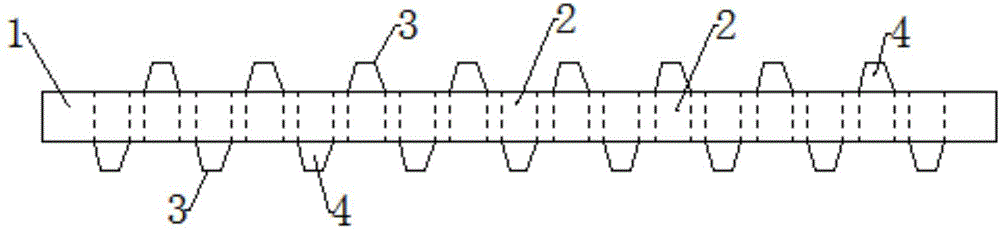

[0041] Such as figure 1 and figure 2 As shown, a 3D foil material includes a base material 1, a plurality of first through holes 2 are arranged in the middle of the base material 1, and protrusions 3 are arranged around the first through holes 2 on the base material 1, and the protrusions 3 are arranged around the first through holes 2. The protrusion 3 is integrally formed with the base material 1; the protrusion 3 is provided with a second through hole 4; the side wall of the second through hole 4 is parallel to the side wall of the protrusion 3, and the second through hole 4 and the first A through hole 2 communicates; the aperture of the first through hole 2 away from the end of the second through hole 4 is greater than or equal to the aperture at the junction of the first through hole 2 and the second through hole 4, and the first through hole 2 and the second through hole The diameter of the joint of the hole 4 is larger than the diameter of the second through hole 4 a...

Embodiment 2

[0050] The other parts of this embodiment are the same as those of Embodiment 1, except that: the substrate 1 is copper foil, the length of the substrate is 800mm, and the width is 285mm.

Embodiment 3

[0052]A preparation method of a positive electrode sheet comprising the 3D foil as described in Example 1: coating 500g of positive electrode slurry on the upper surface of the 3D foil, drying at 90°C, and then rolling to 190 μm , that is, the positive plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com