Pole piece film and preparation method and application thereof

A pole piece and electrode technology, applied in the field of pole piece film and its preparation, can solve the problems of cumbersome process steps, high risk, and strict requirements of mixing process, so as to improve safety performance, simplify process steps, and avoid solvent reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

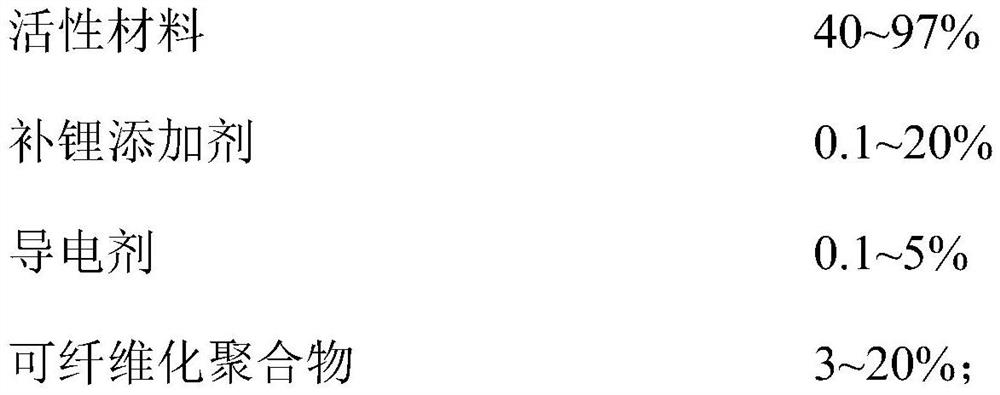

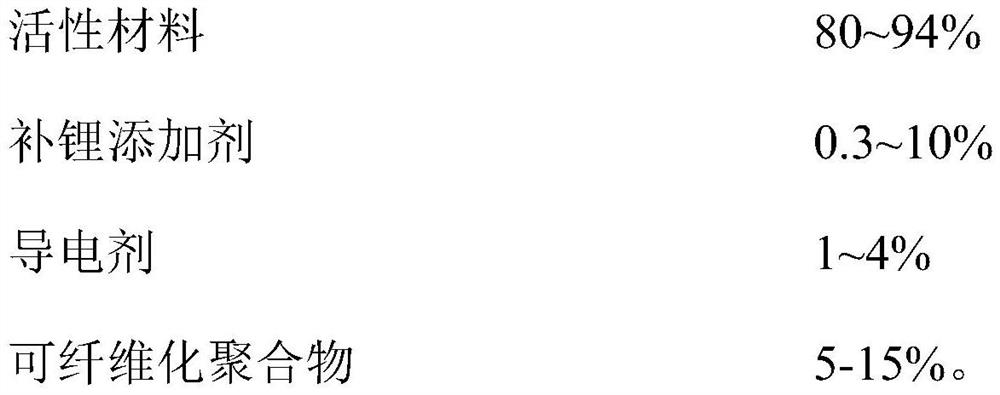

Method used

Image

Examples

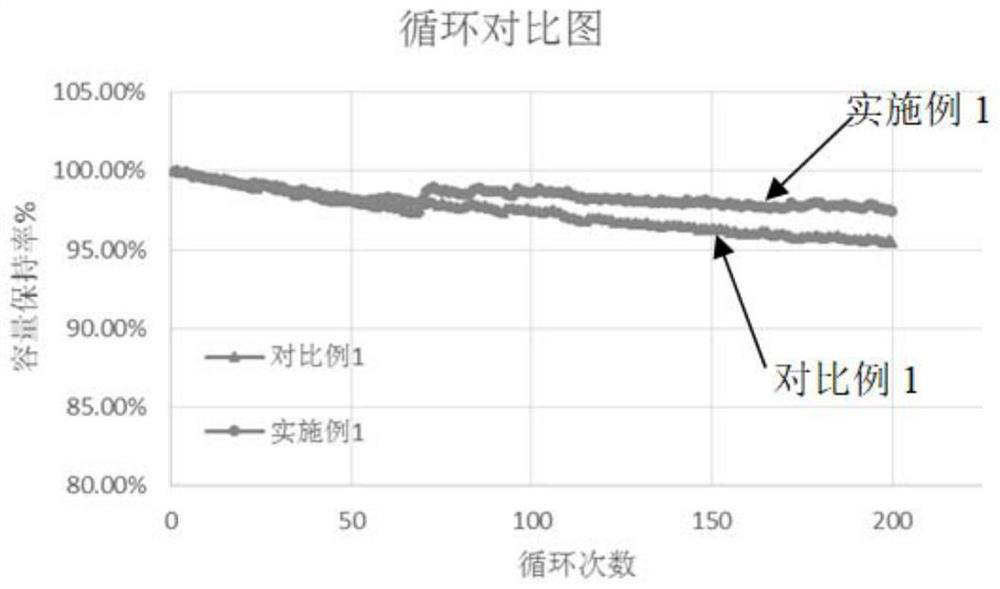

Embodiment 1

[0096] The preparation method of lithium supplement negative electrode:

[0097] In the atmosphere of inert gas Ar gas protection, Si (2.58g), SiO x -SL1600A (2.58g), graphite Gr (31.84g), conductive agent SP (0.8g), CNT (0.2g) and lithium powder (0.5g), with a stirring speed of 20000rpm, stirring and dispersing time 5min, make the powder between Fully contact with each other and mix evenly; then add PTFE (3.2g) firstly at a stirring speed of 2000rpm, stirring and dispersing for 5min, so that the powder and the polymer are fully mixed evenly; then carry out high-speed shear stirring at a speed of 20000rpm, using pulse Stirring method, the single stirring time is 1min, the rest time is 1min, the total stirring time is 20min, and the dry mixed powder is obtained;

[0098] Take an appropriate amount of dry mixed powder and place it on the rolling equipment with adjustable roller gap. The temperature of the roller is set at 80°C, with a roller gap of 80μm and a rolling speed of 5...

Embodiment 2

[0103] The preparation method of lithium supplement negative electrode:

[0104] In an atmosphere protected by inert gas Ar, the SiO x -SL1600A (2.58g), graphite Gr (31.84g), conductive agent SP (0.8g), CNT (0.2g) and lithium silicon alloy Li 12 Si 7 (2.98g), with a stirring speed of 15000rpm, the stirring and dispersing time is 6min, so that the powders are fully contacted and uniformly mixed; then add PTFE (3.2g) with a stirring speed of 2500rpm, and the stirring and dispersing time is 5min, so that the powder and The polymers are fully mixed and evenly mixed; then high-speed shear stirring is performed at a speed of 22000rpm, and pulse stirring is adopted. The single stirring time is 1min, the rest time is 1min, and the total stirring time is 30min; the dry mixed powder is obtained;

[0105] Take an appropriate amount of dry-mixed powder and place it on the roller press equipment with adjustable roller gap. The roller temperature is set at 130°C, with a roller gap of 75μm...

Embodiment 3

[0110] The difference between this embodiment and embodiment 1 is that after adding PTFE, high-speed shearing is carried out directly at a speed of 20000 rpm, and other parameters and conditions are exactly the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com