Preparation method of preoxidation modified high-nickel ternary cathode material

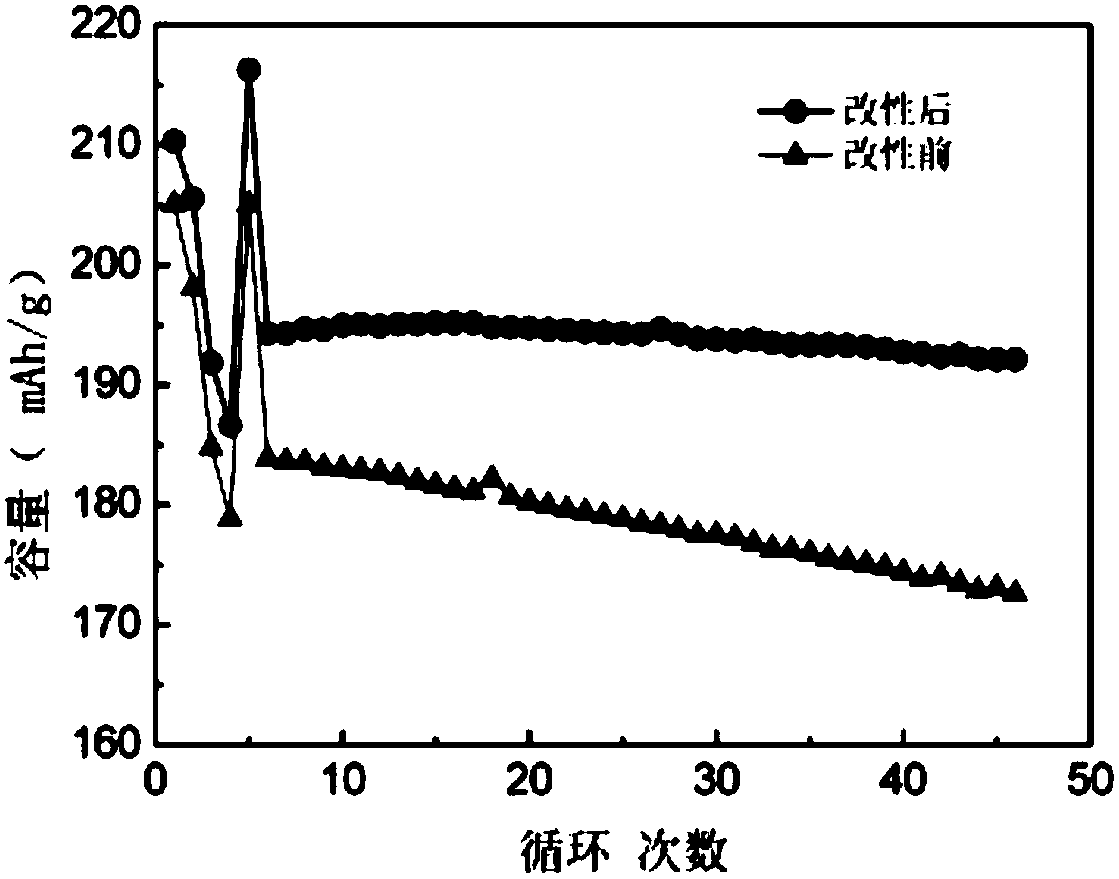

A positive electrode material and pre-oxidation technology, applied in chemical instruments and methods, positive electrodes, active material electrodes, etc., can solve the problems of increased cation mixing, affecting the capacity and cycle performance of high-nickel materials, and achieve reversible capacity increase, improve The first effect and cycle performance, the effect of reducing the degree of mixing of lithium and nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of the high-nickel ternary cathode material that the present invention proposes, comprises the steps:

[0028] S1, 100g high-nickel ternary precursor material Ni 0.85 co 0.1 mn 0.05 (OH) 2 Dissolve 0.5g of manganese nitrate in a deionized water solvent, control the solid content at 30wt% to obtain a slurry; stir the slurry for 1h, then spray dry, and pre-sinter at 400°C for 5h in an air atmosphere to obtain preoxidized High nickel ternary precursor material;

[0029] S2. Mix the pre-oxidized high-nickel ternary precursor material with lithium hydroxide at a Li / Ni molar ratio of 1.03:1, and sinter at 780°C for 15 hours in a pure oxygen atmosphere to obtain pre-oxidized modified high-nickel Ternary cathode material LiNi 0.85 co 0.1 mn 0.05 o 2 ;

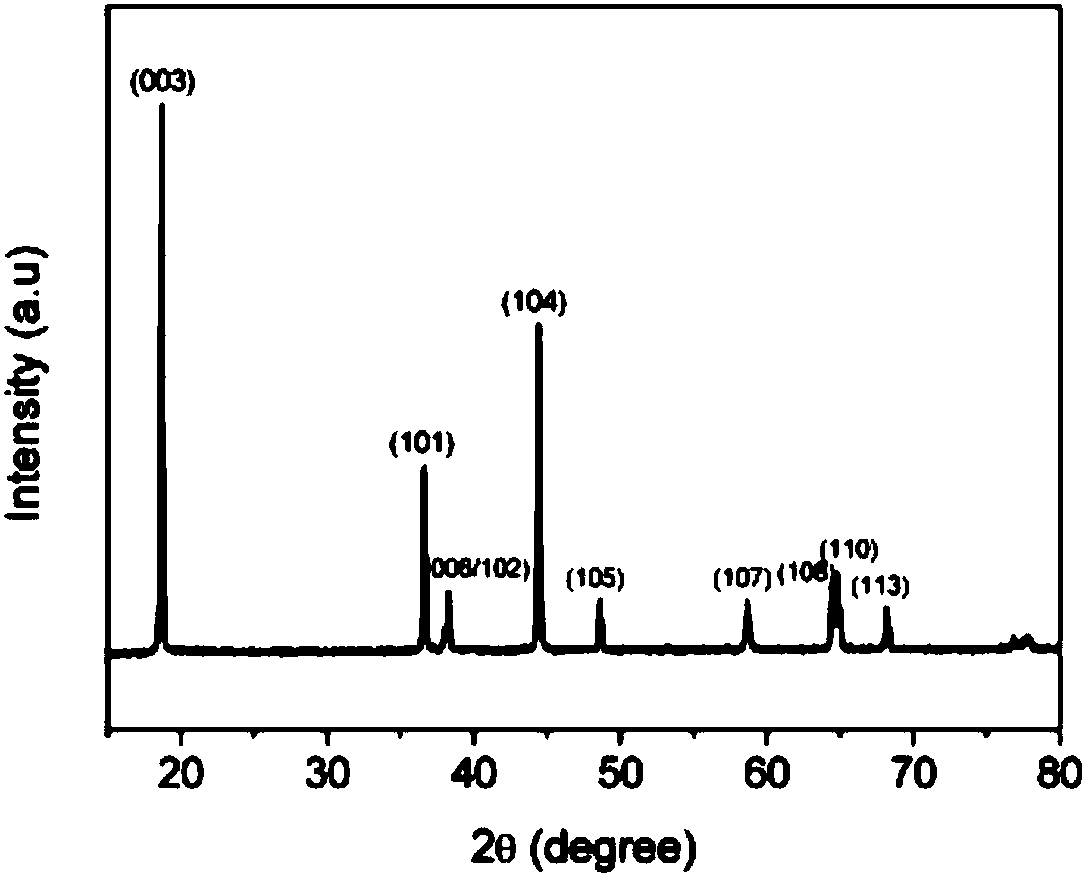

[0030] Carry out XRD and SEM test to the high-nickel ternary positive electrode material of pre-oxidation modification obtained in this embodiment, its XRD is as follows figure 1 As shown, ...

Embodiment 2

[0036] A kind of preparation method of the high-nickel ternary cathode material that the present invention proposes, comprises the steps:

[0037] S1, 100g high-nickel ternary precursor material Ni 0.85 co 0.1 mn 0.05 (OH) 2 Dissolve 2g of cobalt nitrate in an ethanol solvent, control the solid content at 50wt% to obtain a slurry; stir the slurry for 2 hours, then dry it by rotary evaporation, and pre-sinter at 500°C for 3 hours in a pure oxygen atmosphere to obtain a pre-oxidized high Nickel ternary precursor material;

[0038] S2. Mix the pre-oxidized high-nickel ternary precursor material with lithium nitrate according to the Li / Ni molar ratio of 1.05:1, and sinter at 730°C for 20 hours in a pure oxygen atmosphere to obtain a pre-oxidized modified high-nickel ternary Cathode material.

Embodiment 3

[0040] A kind of preparation method of the high-nickel ternary cathode material that the present invention proposes, comprises the steps:

[0041] S1, 100g high-nickel ternary precursor material Ni 0.8 co 0.1 mn 0.1 (OH) 2 Dissolve 5g of potassium nitrate in a deionized water solvent, control the solid content at 40wt% to obtain a slurry; stir the slurry for 2 hours, then dry it by rotary evaporation, and pre-sinter at 500°C for 10 hours in a pure oxygen atmosphere to obtain pre-oxidation High-nickel ternary precursor material;

[0042] S2. Mix the pre-oxidized high-nickel ternary precursor material with lithium carbonate according to the Li / Ni molar ratio of 1.05:1, and sinter at 760°C for 15 hours in a pure oxygen atmosphere to obtain a pre-oxidized modified high-nickel ternary Cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com