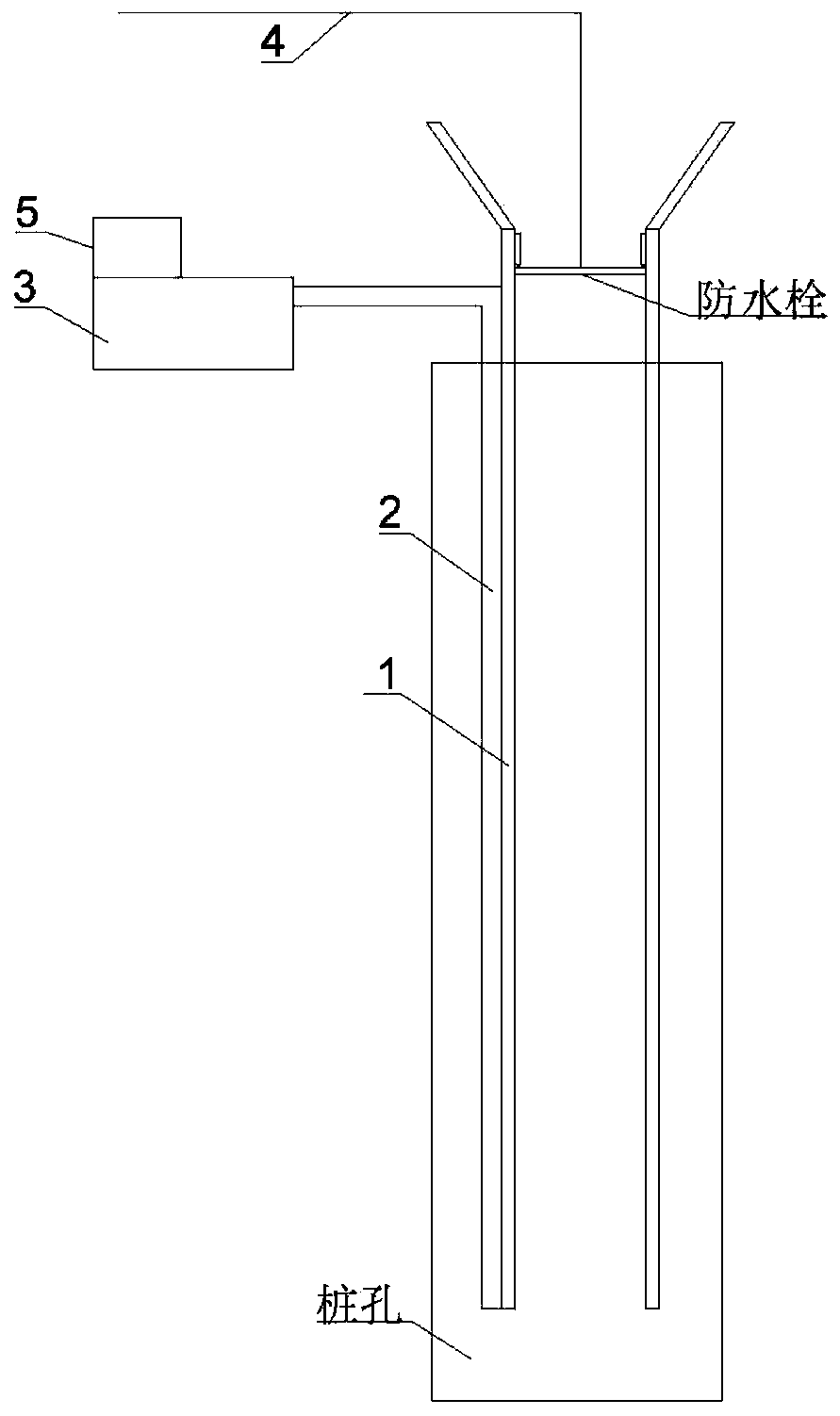

Sediment-free construction device for cast-in-place bored pile

A technology of bored piles and construction devices, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems affecting the quality of piles, achieve the effects of improving the quality of pile foundations, shortening the impact distance, and improving the disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

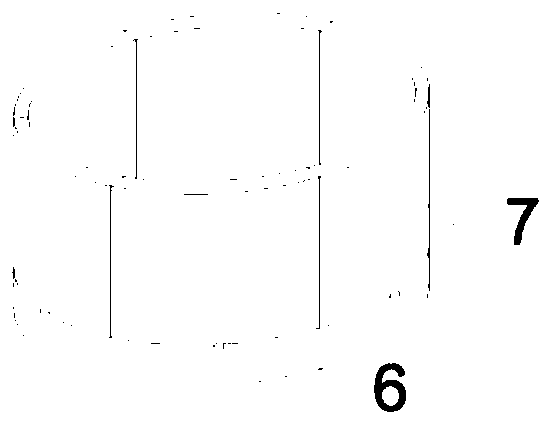

[0030] refer to image 3In this embodiment 1, the waterproof plug is specifically composed of a base 6 and a plurality of arc-shaped enclosures 7, but when the waterproof plug is stably installed in the cast-in-situ pile 1, the moisture in the upper part of the concrete can easily pass through the arc-shaped enclosure. Seepage from the joint between the plate 7 and the base 6 is not conducive to maintaining the water-material ratio of the concrete in the pouring bucket, and affects the quality of the concrete. Therefore, in order to overcome the above defects, a bored pile without sediment construction is provided in this embodiment The device and equipment structure are basically the same as those in Example 1, the main difference being the waterproof plug.

[0031] In this embodiment, the base 6 of the waterproof plug is specifically composed of a bottom plate 8 and a cylindrical baffle 9 fixedly installed on the top thereof, and the arc-shaped enclosure 7 is rotatably conne...

Embodiment 3

[0035] combine Figure 4 , in Example 2, the bottom of the bottom plate 8 is a horizontal plane, so that when it falls out of the bottom of the cast-in-place pile 1 and contacts the sediment muddy liquid, the impact force is too large, which is unfavorable for it to fall into the water smoothly, and the muddy liquid is easy to mix with the concrete, reducing the concrete at the bottom of the pile. Therefore, in order to overcome the above-mentioned defects, a bored pile without sediment construction device is provided in this embodiment. The structure of this device is basically the same as that of Embodiment 2, except that the bottom plate 8 in this embodiment is specifically inverted conical structure.

[0036] Through the above arrangement, when the bottom plate 8 impacts the turbid liquid, the turbid liquid can be guided by the bottom tip of the bottom plate 8, reducing the impact force between the two, so that the concrete flowing out of the cast-in-place pile 1 at the be...

Embodiment 4

[0038] In Examples 1-3, the bottom of the cast-in-place pile 1 always maintains a certain position with the bottom of the pile. The purpose is to allow the concrete to flow out effectively in the later stage and fill the pile hole, so as to realize the purpose of pouring into a pile. The concrete at the bottom of cast-in-situ pile 1 has a certain distance from the bottom of the pile all the time, so that the concrete must have the possibility of impact mixing with the scum and turbid liquid. After the two are mixed, the quality of the pile bottom of the pile must be affected. Therefore, in order to further To improve the quality of piles, this embodiment provides a construction device for bored piles without sediment. The equipment structure is basically the same as that of Embodiment 3, and the main difference is that in this embodiment:

[0039] combine Figure 5 The bottom end of the cast-in-place pile 1 is connected to the diversion enclosure 10 sleeved on its outer wall t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com