High-rate lithium ion battery graphite cathode material and preparation method thereof

A lithium-ion battery and graphite negative electrode technology, applied in battery electrodes, secondary batteries, hybrid capacitor electrodes, etc., can solve the problems of limited rate performance improvement, blocked lithium ion channels, limited economic value, etc., to achieve high first efficiency and high capacity Large, stable product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

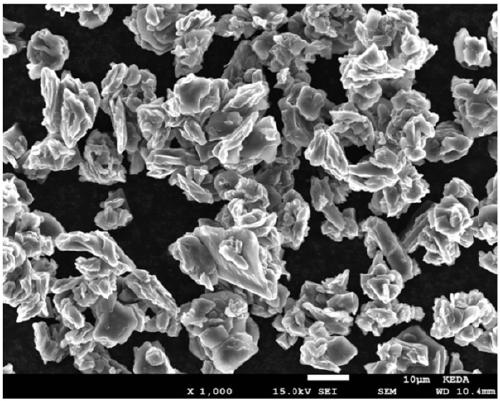

Image

Examples

Embodiment 1

[0029] Preparation method of high rate graphite negative electrode material:

[0030] (1) Crushing and shaping of raw materials: crushing and shaping the needle coke until the particle size D50 is 4-8 μm;

[0031] (2) Graphitization: carry out graphitization high-temperature treatment at 2900° C. for 48 hours on the crushed and shaped material in step (1);

[0032] (3) demagnetization screening: the graphitized sample of step (2) is demagnetized and screened, and the screening adopts a 100-300 mesh vibrating screen;

[0033] (4) Liquid-phase coating granulation: Mix the sieved material with binder and solvent uniformly at a certain ratio at room temperature, then add it to a fusion machine (rotating speed 500 rpm, time 20 minutes) for treatment, and place Carbonization treatment in a carbonization furnace, the carbonization temperature and time are 800 ° C, 4 hours; the material accounts for 80% of the total mass; the binder is petroleum pitch, the solvent is n-hexane, and it...

Embodiment 2

[0037] Preparation method of high rate graphite negative electrode material:

[0038] (1) Crushing and shaping of raw materials: crushing and shaping the needle coke until the particle size D50 is 4-8 μm;

[0039] (2) Graphitization: carry out graphitization high-temperature treatment at 3000° C. for 48 hours on the crushed and shaped material in step (1);

[0040] (3) demagnetization screening: the graphitized sample of step (2) is demagnetized and screened, and the screening adopts a 100-300 mesh vibrating screen;

[0041] (4) Liquid-phase coating granulation: mix the sieved material with binder and solvent uniformly at a certain ratio at room temperature, add it to a fusion machine (800 rpm, 40 minutes) for processing, and place Carbonization treatment in a carbonization furnace, the carbonization temperature and time are 1000 ° C, 4 hours; the material accounts for 90% of the total mass; the binder is phenolic resin, the solvent is ethanol, and its mass ratio is 1:4, acco...

Embodiment 3

[0045] Preparation method of high rate graphite negative electrode material:

[0046] (1) Crushing and shaping of raw materials: crushing and shaping the petroleum coke until the particle size D50 is 4-8 μm;

[0047] (2) Graphitization: carry out graphitization high-temperature treatment at 3100° C. for 48 hours on the crushed and shaped material in step (1);

[0048] (3) demagnetization screening: the graphitized sample of step (2) is demagnetized and screened, and the screening adopts a 100-300 mesh vibrating screen;

[0049] (4) Liquid-phase coating granulation: mix the sieved material with binder and solvent uniformly at a certain ratio at room temperature, add it to a fusion machine (800 rpm, 40 minutes) for processing, and place Carbonization treatment in a carbonization furnace, the carbonization temperature and time are 1000 ° C, 2 hours; the material accounts for 90% of the total mass; the binder is phenolic resin, the solvent is ethanol, and its mass ratio is 1:3, acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com