Silicon-carbon composite material, preparation method thereof and negative pole for lithium-ion battery

A technology of silicon-carbon composite materials and carbon materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high cost and high price, and achieve the effects of low production cost, low equipment requirements, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1: Using wheat straw as raw material to prepare biomass source carbon material

[0074] 1) The wheat straw material was crushed, reacted with 4 mol / L hydrochloric acid at 150 degrees Celsius for 10 h, washed three times with deionized water and dried. Then carry out carbonization treatment at 600 degrees Celsius under the protection of an inert gas such as nitrogen, and then wash with 3mol / L hydrofluoric acid and stir for 1-6h. Finally, the wheat straw biomass source carbon material is obtained by washing and drying with deionized water.

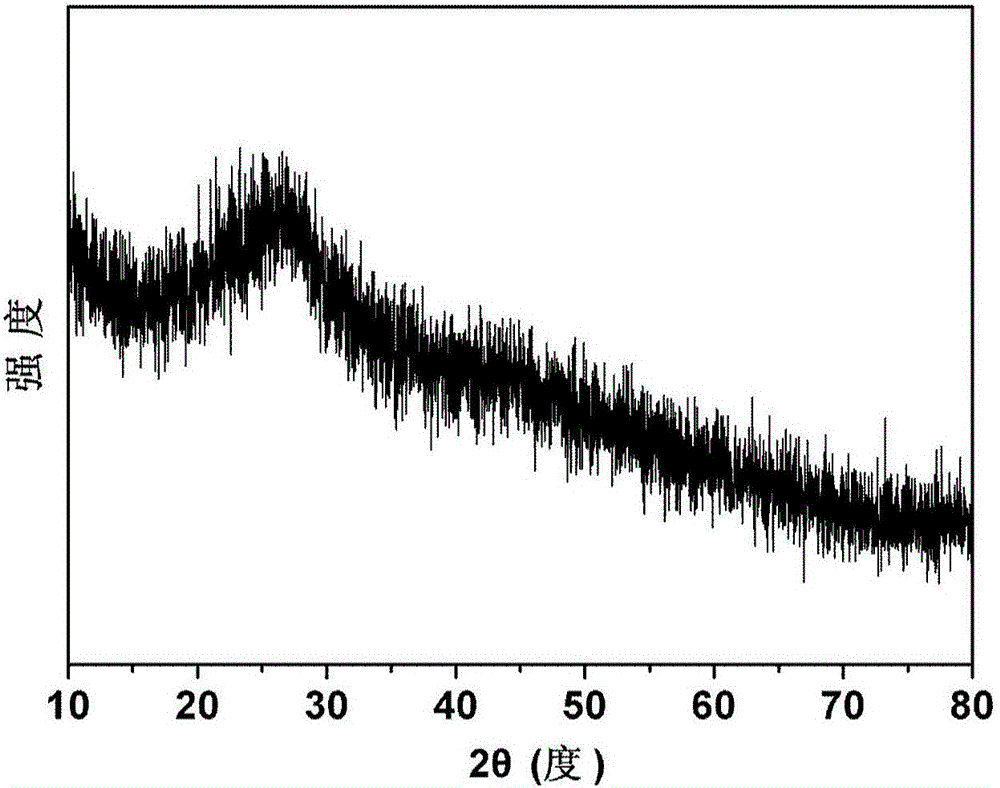

[0075] 2) Carry out X-ray diffraction analysis with an X-ray powder diffractometer (Philips X'Pert Super diffract meter), figure 1 It is the X-ray diffraction spectrum of the powder obtained in this embodiment. It can be seen from the figure that there is no clear and sharp diffraction peak at 2θ in the range of 10-80 degrees in the X-ray diffraction spectrum, and a steamed bun peak appears between 20 and 30 degrees, which m...

Embodiment 2

[0077] Example 2: Using the biomass-sourced carbon material prepared from wheat straw in Example 1 as a substrate, a silicon-carbon composite material was prepared by vapor deposition.

[0078] 1) Put the prepared biomass-sourced carbon material into the reaction chamber. Commercially available acetylene (mixed gas of acetylene and argon, volume ratio Ar:C 2 h 2 = 9: 1) loaded silicon tetrachloride (the volume ratio of commercially available acetylene and silicon tetrachloride is 20: 1) passes in the reaction chamber, heats 550 degrees centigrade in the gas atmosphere containing acetylene and silicon tetrachloride, keeps After 8 hours, the silicon-carbon composite material was prepared after the reaction.

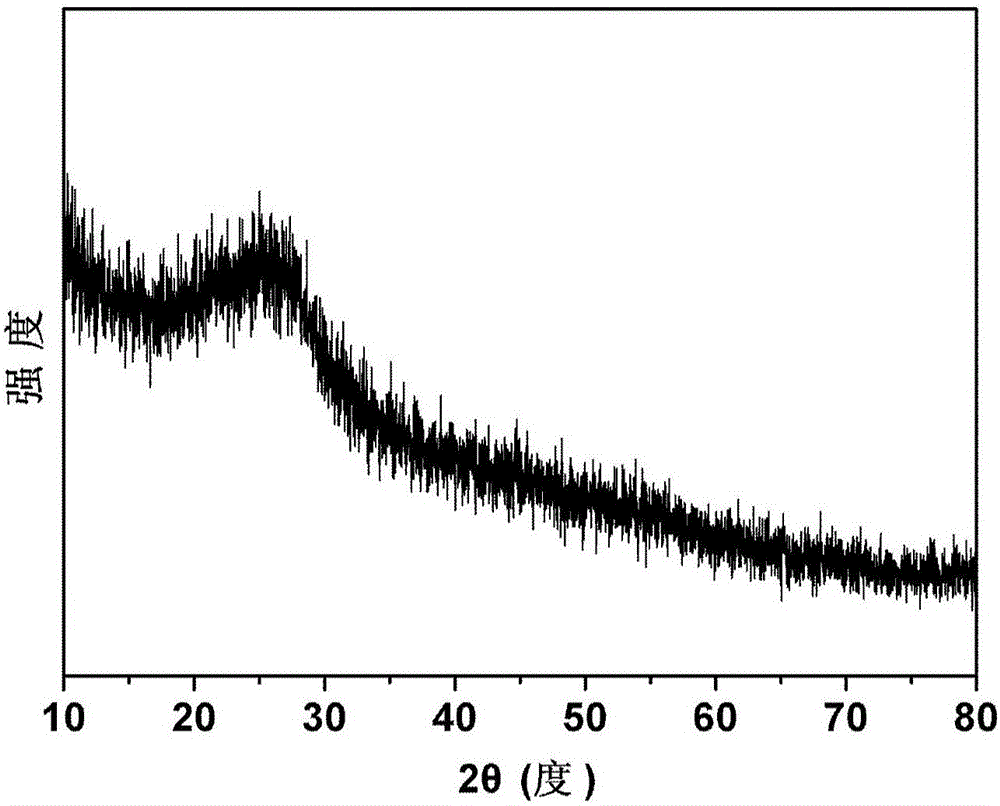

[0079] 2) image 3 It is the X-ray diffraction spectrum of the powder obtained in this embodiment. The spectrogram shows that the powder is an amorphous phase, and no other impurities are formed.

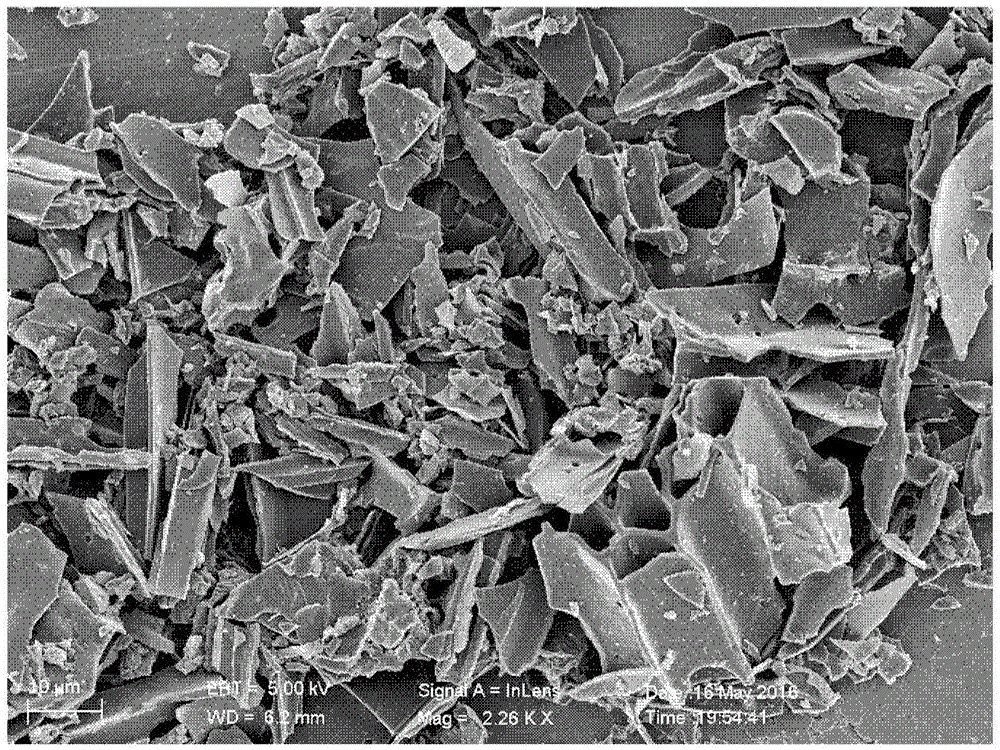

[0080] 3) Figure 4 It is an energy dispersive X-ray detection element...

Embodiment 3

[0081] Example 3: Applying the silicon-carbon composite material obtained in Example 2 to the performance research of lithium-ion battery anode materials

[0082] The products in the above-mentioned Example 2 are packed into CR2016 button cells (Shenzhen Pengxiang Yunda Machinery Technology Co., Ltd.), respectively, with the lithium sheet as the counter electrode, the polyolefin porous film (Celgard 2500) as the diaphragm, and the LiPF 6 A mixed solution of ethylene carbonate (EC) and dimethyl carbonate (DMC) (volume ratio 1:1) was used as the electrolyte, and the CR2016 battery was completed in an argon atmosphere glove box. The silicon carbon electrode is made of 60% by weight of the biomass silicon carbon composite material in Example 2, 20% by weight of sodium carboxymethylcellulose adhesive, 20% of conductive carbon black, and water. The lining of the electrode film The bottom is metal copper foil. Conduct electrical performance tests at a test temperature of 25 degrees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com