Nuclear shell structured packing/polymer-based composite material and preparation method thereof

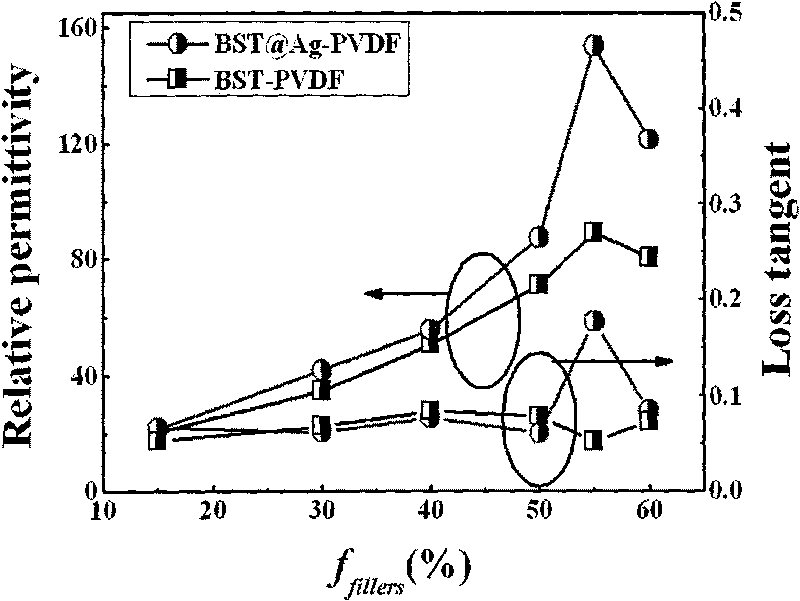

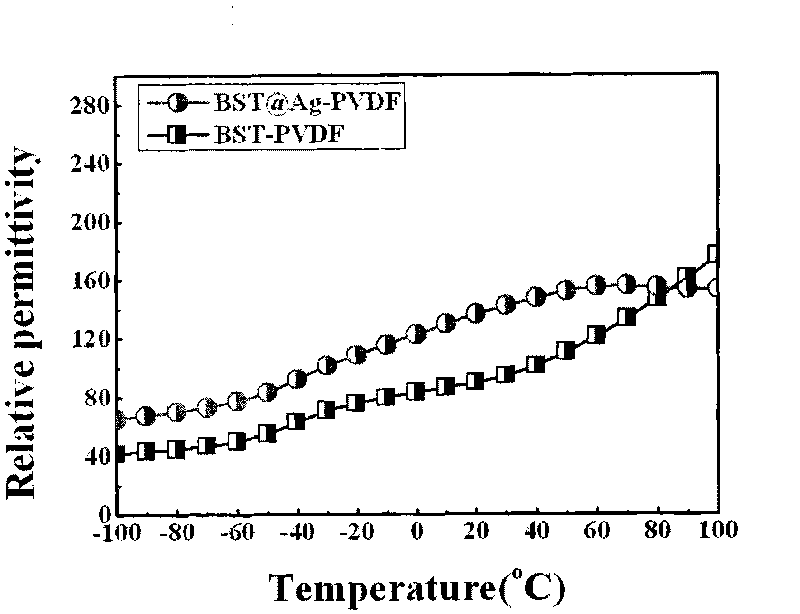

A core-shell structure and composite material technology, applied in fibrous fillers, chemical instruments and methods, dyed low molecular organic compound processing and other directions, can solve the problem that the dielectric constant of composite materials cannot be effectively improved, and achieve process parameters that are easy to control , The effect of increasing the dielectric constant and reducing the dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of ceramic particles: The BST ceramic block is pulverized by a high-energy ball mill to produce ceramic particles with a particle size of 10nm-100nm.

[0041] 2. Surface treatment of ceramic particles: Take 100 parts of crushed BST particles by volume, dry them at 90°C for 36 hours, then add 5 parts of 2mol / l acrylic acid and 100 parts of absolute ethanol to the dried BST particles. The solution was sonicated for 4 hours, so that the surface of the ceramic powder was treated with acrylic acid.

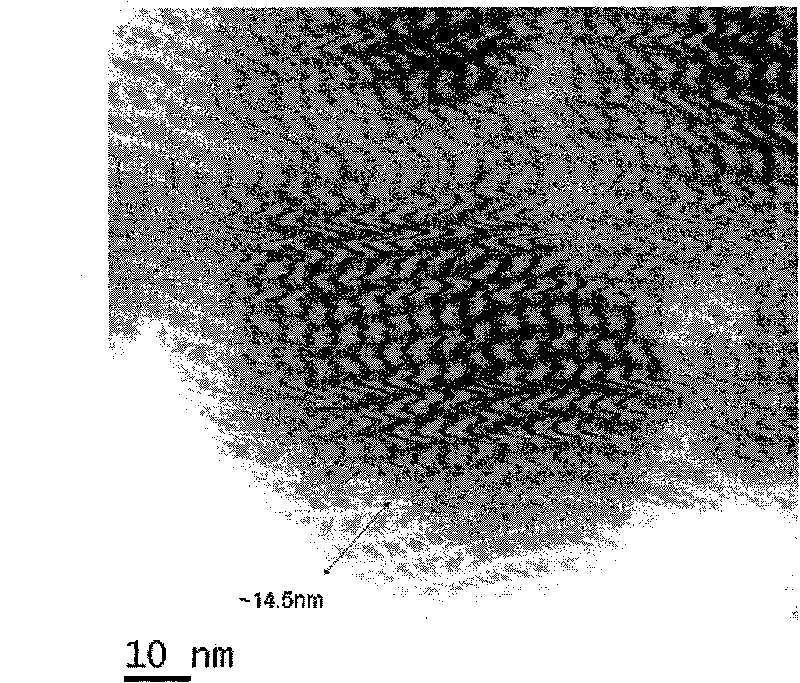

[0042] 3. Preparation of core-shell structure filler: take 20 grams of acrylic acid-treated BST ceramic particles and ultrasonically disperse them in 1 liter of acetone to obtain a suspension containing BST particles; prepare a silver nitrate solution with a concentration of 0.5 mol / liter, and add a concentration of 1 mol / liter of ammonia water to make it a complex solution, add the suspension in step 3 to the complex solution, the volume ratio of the suspension t...

Embodiment 2

[0047] 1. Preparation of ceramic particles: BT ceramic blocks are pulverized by high-energy ball milling to produce ceramic particles with a particle size of 100nm-10um.

[0048] 2. Surface treatment of ceramic particles: take 100 parts of crushed BT particles by volume, dry at 150°C for 12 hours, then add 2 parts of 2mol / l acrylic acid and 50 parts of absolute ethanol to the dried BT particles and mix The surface of the ceramic powder was treated with acrylic acid by sonicating in solution for 1 hour.

[0049] 3. Preparation of core-shell structure filler: Take 20 grams of acrylic acid-treated BT ceramic particles and ultrasonically disperse them in 1 liter of acetone to obtain a suspension containing BT particles; prepare a silver nitrate solution with a concentration of 0.5 mol / liter, and add a concentration of 1 mol / liter of ammonia water to make it a complex solution, add the suspension in step 3 to the complex solution, the volume ratio of the suspension to the complex s...

Embodiment 3

[0053] 1. Preparation of ceramic particles: BT ceramic blocks are pulverized by high-energy ball milling to produce ceramic particles with a particle size of 100nm-10um.

[0054] 2. Surface treatment of ceramic particles: take 100 parts of crushed BT particles by volume, dry at 150°C for 12 hours, then add 2 parts of 2mol / l acrylic acid and 50 parts of absolute ethanol to the dried BT particles and mix The surface of the ceramic powder was treated with acrylic acid by sonicating in solution for 1 hour.

[0055] 3. Preparation of core-shell structure filler: Take 20 grams of acrylic acid-treated BT ceramic particles and ultrasonically disperse them in 1 liter of acetone to obtain a suspension containing BT particles; prepare a silver nitrate solution with a concentration of 0.5 mol / liter, and add a concentration of 1 mol / liter of ammonia water to make it a complex solution, add the suspension in step 3 to the complex solution, the volume ratio of the suspension to the complex s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com