Method for chemically modifying inorganic filler with graphene oxide, product and application

A technology of inorganic fillers and graphene chemistry, applied in chemical instruments and methods, inorganic pigment processing, fibrous fillers, etc. It is vulnerable to damage and other problems, and achieves the effect of improving affinity, good application prospects, and enhancing interfacial adhesion and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

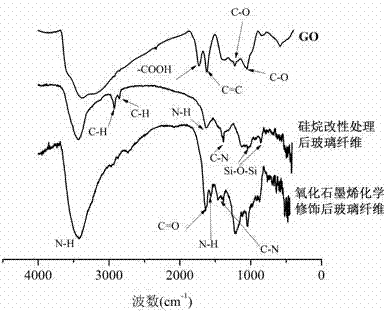

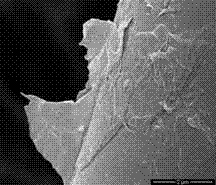

[0059] 1. Surface hydroxylation modification: Make a mixed solution of 98wt% concentrated sulfuric acid and 30wt% hydrogen peroxide at a volume ratio of 7:3, add glass fiber with a solution mass of 10wt% to it, and soak at 90°C for 30 minutes. Wash the glass fiber three times with deionized water, and dry it in an oven at 100°C until constant weight.

[0060] 2. Coupling agent modification: Prepare a solution with water and absolute ethanol at a mass ratio of 45:5, and adjust the pH of the solution to 6.0 with glacial acetic acid. Add the coupling agent dropwise to the solution while stirring until the concentration of the coupling agent in the solution is 0.5wt%, and continue stirring for 1.5h to make it hydrolyze. Adjust the hydrolyzed coupling agent solution to pH = 6.0, add 10wt% glass fiber to it, stir at 60°C for 40min, filter with suction, rinse with deionized water for 3 times, and dry in an oven at 100°C until constant weight.

[0061] 3. Preparation of GO aqueous s...

Embodiment 2

[0065] 1. The preparation of GO solution, the surface hydroxylation of glass fiber and the modification method of coupling agent are the same as in Example 1.

[0066] 2. Chemical modification of glass fiber surface by GO: Add GO solution to MES buffer solution with a concentration of 1mol / L, adjust the pH of the mixture to 5.8-6.0, and adjust the concentration of GO in the mixture to 2.0mg / ml ; According to the content of -COOH in the measured GO, and according to -COOH:EDC (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride):NHS (N-hydroxysuccinyl imine) at a molar ratio of 1:15:20, EDC and NHS were added to the solution in sequence, and the mixed solution was sonicated for 2 h.

[0067] Add glass fiber treated with silane coupling agent with 10% solution mass, and stir magnetically for 36 h at room temperature to carry out amidation reaction. After the reaction, let it stand still, filter, wash the glass fiber three times with deionized water, and finally dry it i...

Embodiment 3

[0069] 1. The surface hydroxylation of glass fibers and the modification method of coupling agent are the same as in Example 1.

[0070] 2. Preparation of GO aqueous solution: Add 1.5g of sodium nitrate, 3g of graphite powder and 138g of concentrated sulfuric acid (98%) into the there-necked flask under ice bath conditions, stir for 30 min, then slowly add 9g of potassium permanganate into the there-necked flask , stirred for 30 min. Heated to 35 °C and stirred thoroughly for 24 h to obtain a brown suspension. Slowly add 150ml of deionized water to the suspension, stir, raise the temperature, continue the reaction at 98°C for 10min, and cool to room temperature. Pour the reaction solution into 500ml deionized water while stirring, add 15ml H 2 o 2 (30%) solution, let stand for 24h. The precipitate in the lower layer was taken out, and centrifuged and washed three times with deionized water at 8000 r / min, each time for 8 min. The product was dialyzed against deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com