Composite cement grinding aid

A technology of compounding cement and grinding aids, which is applied in the field of cement additives, can solve the problems that cement enterprises cannot save costs, the grinding efficiency of cement grinding aids is low, and the enhancement effect is not obvious, so as to achieve good energy-saving effect and reduce over-grinding phenomenon, the effect of optimizing cement particle gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Each component is weighed according to the following percentage by weight: triethanolamine 10%, diisoalcohol isopropanolamine 25%, polyalcohol amine 18%, sodium polyphosphate 7%, lignosulfonate 15%, molasses 8% and Water 17%, weighed and put into the same beaker to mix and stir evenly to obtain a composite cement grinding aid.

[0017] The lignosulfonate is a mixture of 60% calcium lignosulfonate and 40% magnesium lignosulfonate in parts by weight.

Embodiment 2

[0019] Each component is weighed according to the following percentage by weight: triethanolamine 12%, diisoalcohol isopropanolamine 24%, polyalcohol amine 17%, sodium polyphosphate 8%, lignosulfonate 14%, molasses 9% and 16% water, weighed and put into the same beaker to mix and stir evenly to obtain a composite cement grinding aid.

[0020] The lignosulfonate is a mixture of 60% calcium lignosulfonate and 40% magnesium lignosulfonate in parts by weight.

Embodiment 3

[0022] Each component is weighed according to the following percentage by weight: triethanolamine 14%, diisoalcohol isopropanolamine 20%, polyalcohol amine 15%, sodium polyphosphate 9%, lignosulfonate 16%, molasses 10% and 16% water, weighed and put into the same beaker to mix and stir evenly to obtain a composite cement grinding aid.

[0023] The lignosulfonate is a mixture of 60% calcium lignosulfonate and 40% magnesium lignosulfonate in parts by weight.

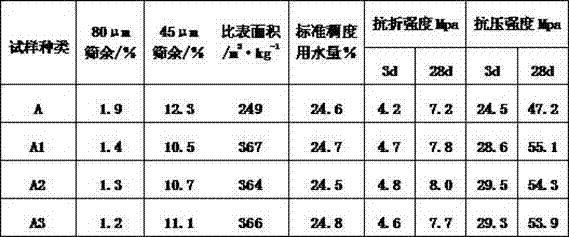

[0024] The cement raw material is used for the test small grinding. The weight percentage of each component of the cement raw material is: clinker 75%, fly ash 10%, slag 10% and gypsum 5%, take the same proportion of materials, no cement grinding aid is added The blank sample is denoted as A, and 0.03% of the composite cement grinding aids described in embodiment one, embodiment two and embodiment three are mixed, and are respectively denoted as A1, A2 and A3, and the grinding time is 25 minutes, and the obtained cement T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com