Novel preparation method for mono ethanol diisopropanolamine

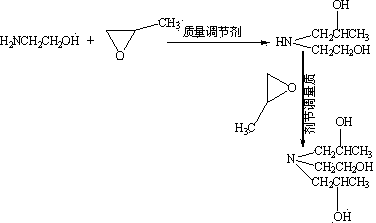

A technology of ethanoldiisopropanolamine and ethanolamine, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of aminohydroxy compounds, etc., can solve the problems of complex preparation process, low yield and high cost, and achieves easy operation, The effect of high yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add 24.4g ethanolamine, 0.021g quality regulator, 9.3g propylene oxide in the 125ml four-neck bottle equipped with mechanical stirring device, circulating condensing device, thermometer, pear-shaped separating funnel, stir evenly, and the temperature to be reacted is at 50~ Between 60°C, turn on the circulating condensing device, drop 37.2g of propylene oxide into the four-necked bottle through the separatory funnel, control the temperature in the reaction bottle at 50~60°C, and keep warm for 1.5 h to obtain the finished product of monoethanol diisopropanolamine. Sampling was carried out for gas chromatographic analysis, and the yield was 97.6%.

Embodiment 2

[0015] Add 24.4g of ethanolamine, 0.042g of quality regulator, and 9.3g of propylene oxide into a 125ml four-necked bottle equipped with a mechanical stirring device, a circulating condensing device, a thermometer, and a pear-shaped separating funnel, and stir evenly until the reaction temperature is 50~ Between 60°C, turn on the circulating condensing device, drop 37.2g of propylene oxide into the four-necked bottle through the separatory funnel, control the temperature in the reaction bottle at 50~60°C, and keep warm for 1.5 h to obtain the finished product of monoethanol diisopropanolamine. Sampling was carried out for gas chromatographic analysis, and the yield was 95.2%.

Embodiment 3

[0017] Add 24.4g ethanolamine, 0.021g quality regulator, 11.6g propylene oxide in the 125ml four-necked bottle equipped with mechanical stirring device, circulating condensing device, thermometer, and pear-shaped separating funnel, stir evenly, and wait for the reaction temperature to be at 50~ Between 60°C, turn on the circulating condensing device, drop 34.9g of propylene oxide into the four-necked bottle through the separatory funnel, control the temperature in the reaction bottle at 50~60°C, and keep warm for 1.5 h to obtain the finished product of monoethanol diisopropanolamine. Sampling was carried out for gas chromatographic analysis, and the yield was 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com