High-strength rare earth-doped up-conversion luminescence nanometer material and preparation method thereof

A nano-material, rare earth doping technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low efficiency, complicated operation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Take 2.5mL0.4M 78%Y(NO 3 ) 3 ,20%Yb(NO 3 ) 3 ,2%Er(NO 3 ) 3 Put the aqueous solution in a beaker, add 16mL of deionized water and 18.5mL of ethanol, then add 7ml of oleic acid, stir to form solution A. Weigh 504 mg of NaF and dissolve it in 10 mL of water and 10 mL of ethanol, and stir to form solution B. After stirring A for 30 minutes, add solution B dropwise to A under stirring. After the dropwise addition, sonicate for half an hour, transfer to a 75mL hydrothermal kettle, screw the lid on, and heat in an oven at a heating temperature of 200 degrees. React for 10 hours, cool down, pour off the supernatant, collect the solid below, wash twice with a mixture of ethanol and water, centrifuge, and dry to obtain NaYF complexed with oleic acid ligands 4 : Yb, Er.

Embodiment 2~7

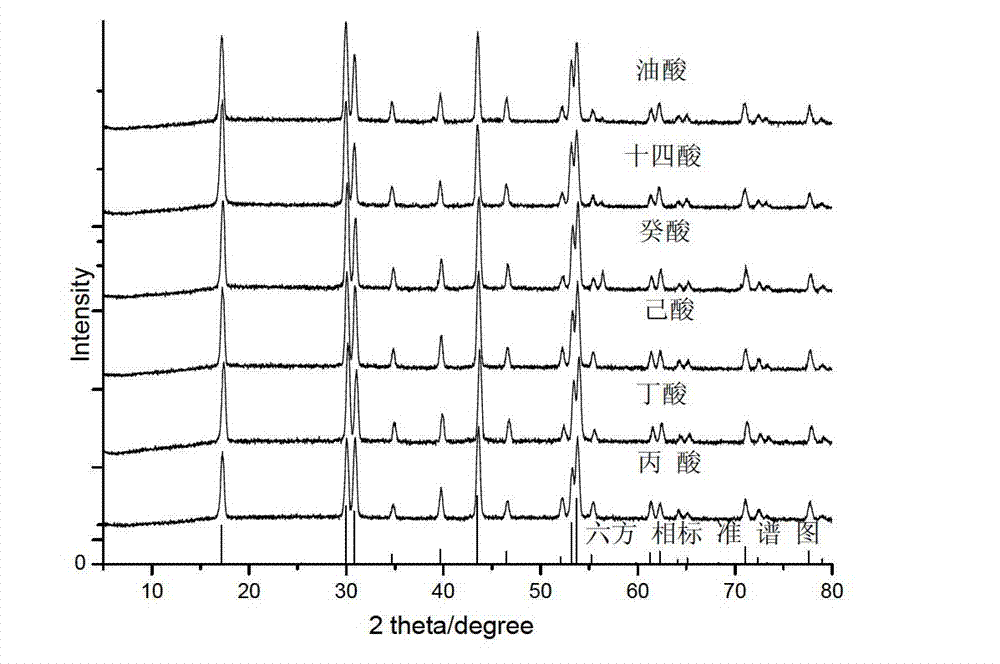

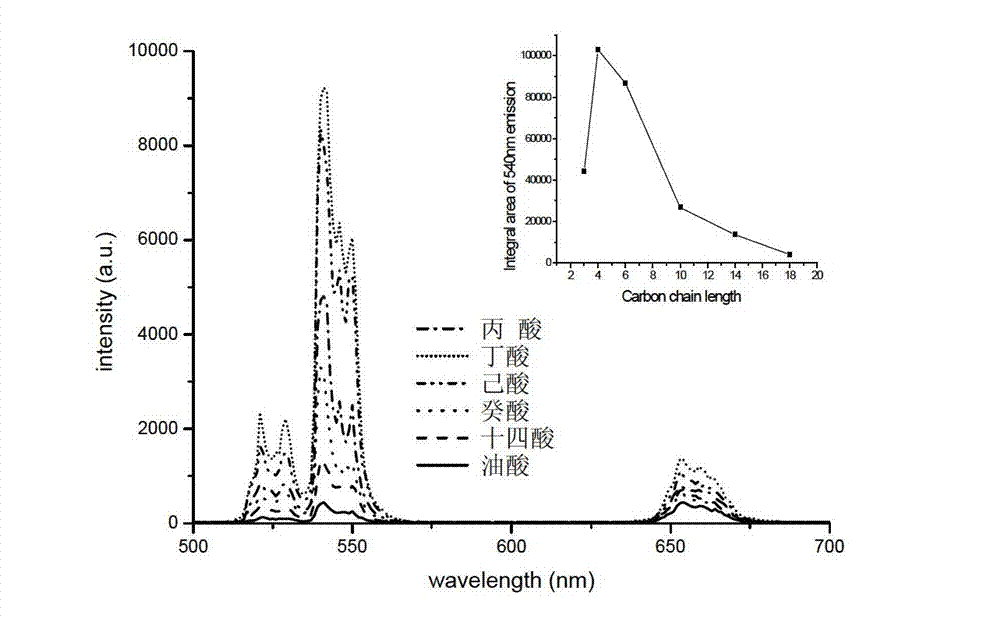

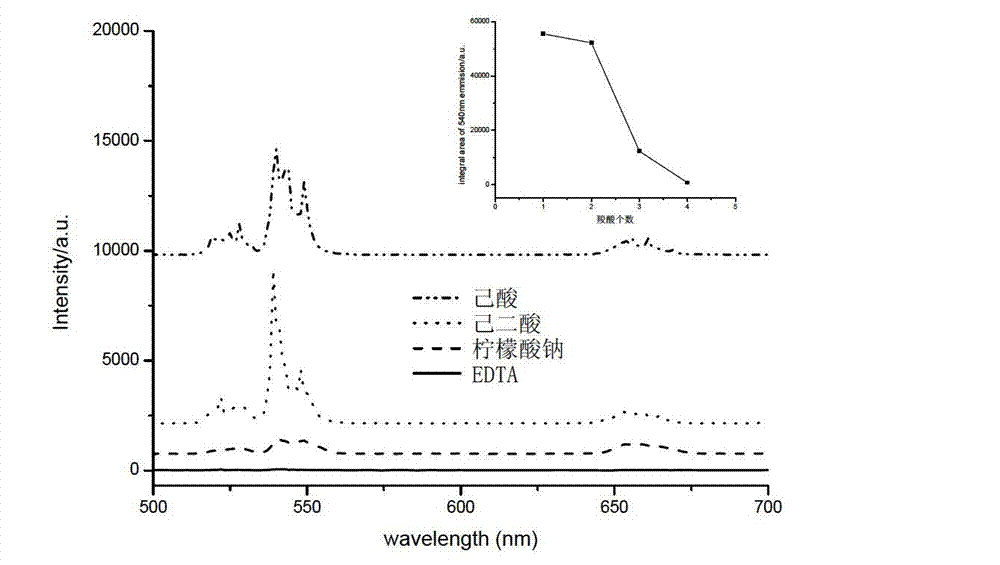

[0082] Take 2.5mL0.4M 78%Y(NO 3 ) 3 ,20%Yb(NO 3 ) 3 ,2%Er(NO 3 ) 3 Put the aqueous solution in a beaker, add 14mL of deionized water and 16.5mL of ethanol, add 7ml of propionic acid, butyric acid, hexanoic acid, capric acid, myristic acid or oleic acid and 0.7g of NaOH, and stir to form solution A. Weigh 504 mg of NaF and dissolve it in 10 mL of water and 10 mL of ethanol, and stir to form solution B. After stirring A for 30 minutes, add solution B dropwise to A under stirring. After the dropwise addition, sonicate for half an hour, transfer to a 75mL hydrothermal kettle, screw the lid on, and heat in an oven at a heating temperature of 200 degrees. React for 7 hours, cool down, pour off the supernatant, collect the solid below, wash twice with a mixture of ethanol and water, centrifuge, and dry to obtain NaYF complexed with carboxylic acid ligands of different carbon chain lengths 4 : Yb, Er nanocrystals.

Embodiment 8~9

[0084] Take 2.5mL0.4M 78%Y(NO 3 ) 3 ,20%Yb(NO 3 ) 3 ,2%Er(NO 3 ) 3 Aqueous solution in a beaker, add 17.5mL of deionized water and 20mL of ethanol, add 1mmol of benzoic acid or salicylic acid to form solution A. Weigh 504 mg of NaF and dissolve it in 10 mL of water and 10 mL of ethanol, and stir to form solution B. After stirring A for 30 minutes, add solution B dropwise to A under stirring. After the dropwise addition, sonicate for half an hour, transfer to a 75mL hydrothermal kettle, screw the lid on, and heat in an oven at a heating temperature of 200 degrees. React for 7 hours, cool down, pour off the supernatant, collect the solid below, wash twice with a mixture of ethanol and water, centrifuge, and dry to obtain NaYF complexed with benzoic acid or salicylic acid 4 : Yb, Er nanocrystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com