Aluminate cement-based carbon dioxide corrosion resistant cement system for cementing of well

A technology of aluminate cement and carbon dioxide, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve potential safety hazards, poor temperature resistance and anti-pollution performance, and cannot meet the requirements of long-term sealing of oil and gas wells, etc. problems, to achieve the effects of prolonging service life, improving cementing quality, and excellent CO2 corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

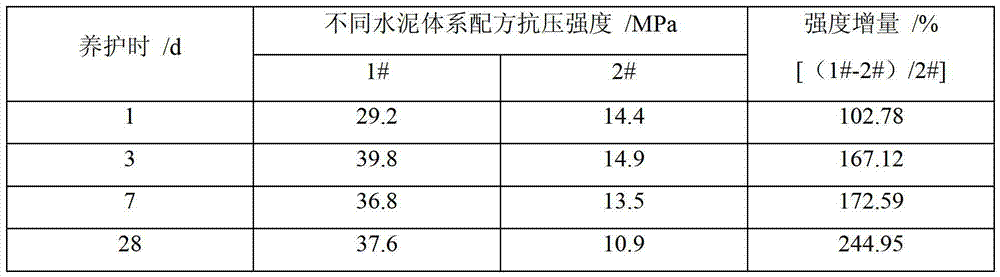

Embodiment 1

[0024] An aluminate cement-based carbon dioxide corrosion-resistant cement system for well cementing: 100 parts of aluminate cement, 40 parts of water, 10 parts of sodium hexametaphosphate, 0.5 part of oil well cement defoamer, and no retarder. The sample number of the cement system is 1#. Among them, the aluminate cement is produced by Zhengzhou Zhongfa Special Cement Melt Co., Ltd., and the model is CA-50. The influence of sodium hexametaphosphate on aluminate cement has not been tested, and no retarder is added to this system.

Embodiment 2

[0026] An aluminate cement-based carbon dioxide corrosion-resistant cement system for well cementing: 100 parts of aluminate cement, 40 parts of water, 10 parts of sodium hexametaphosphate, 0.5 parts of oil well cement defoamer, and 3 parts of sodium silicate. The sample number of the cement system is Z1#. This system is compared with Example 1, in order to test the impact of retarder on the compressive strength of 1# system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com