Packer liquid capable of reducing carbon dioxide corrosion at high temperature under high pressure and preparation method thereof

A technology of carbon dioxide, high temperature and high pressure, applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of not reducing carbon dioxide packer fluid, increasing corrosiveness, and not meeting packer fluid anticorrosion Requirements and other issues, to achieve the effect of easy completion operation, low corrosion, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares the packing fluid of the present invention according to the following steps:

[0027] (1) Compound salt weighting agent preparation: Take 850g of potassium pyrophosphate and 150g of sodium diethylenetriaminepentamethylene phosphonate, stir and mix evenly to prepare a compound salt weighting agent;

[0028] (2) Packing fluid preparation: add 3g NaOH to 1000g fresh water, stir for 5 minutes to fully dissolve; then add 940g compound salt weighting agent, stir for 30 minutes to fully dissolve; finally add 2g sodium sulfite oxygen scavenger and 50g 1-aminoethyl-1 - Carboxymethyl-2-heptadecenyl imidazoline chloride corrosion inhibitor, stir evenly, settle and filter at rest, and obtain a density of 1.45g / cm 3 the packing fluid.

Embodiment 2

[0029] Embodiment 2 prepares the packing fluid of the present invention according to the following steps:

[0030] (1) Compound salt weighting agent preparation: Take 800g of potassium pyrophosphate and 200g of potassium hexamethylenediamine tetramethylene phosphonate, stir and mix evenly to prepare a compound salt weighting agent;

[0031] (2) Packing fluid preparation: add 2g NaOH to 1000g fresh water, stir for 5 minutes to fully dissolve; then add 760g compound salt weighting agent, stir for 30 minutes to fully dissolve; finally add 2g sodium sulfite oxygen scavenger and 30g 1-aminoethyl-1 - Carboxymethyl-2-heptadecenyl imidazoline chloride corrosion inhibitor, stir evenly, settle and filter at rest to obtain a density of 1.25g / cm 3 the packing fluid.

Embodiment 3

[0032] Embodiment 3 prepares the packing fluid of the present invention according to the following steps:

[0033] (1) Compound salt weighting agent preparation: Take 850g of potassium pyrophosphate and 150g of sodium diethylenetriaminepentamethylene phosphonate, stir and mix evenly to prepare a compound salt weighting agent;

[0034] (2) Packing fluid preparation: add 5g NaOH to 1000g fresh water, stir for 5 minutes to fully dissolve; then add 1400g compound salt weighting agent, stir for 30 minutes to fully dissolve; finally add 3g sodium sulfite oxygen scavenger and 50g 1-aminoethyl-1 -Carboxymethyl-2-heptadecenyl imidazoline chloride corrosion inhibitor, stir evenly, settle and filter at rest, and obtain a density of 1.60g / cm 3 the packing fluid.

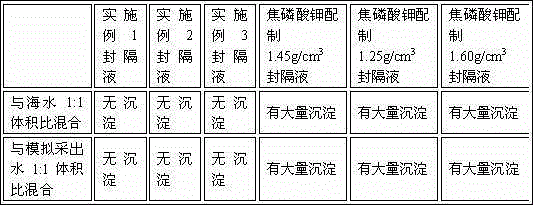

[0035] 1. Compatibility evaluation of packer fluid with seawater and produced water: Mix the packer fluid prepared in Examples 1-3 with seawater and simulated produced water at a volume ratio of 1:1, observe the occurrence of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com