Corrosion inhibitor for inhibiting corrosion of high-temperature high-pressure carbon dioxide and preparation method thereof

A carbon dioxide, high temperature and high pressure technology, applied in the field of corrosion inhibitor and its preparation, can solve the problems of poor effect and high concentration of use, and achieve the effect of less use, corrosion prevention and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

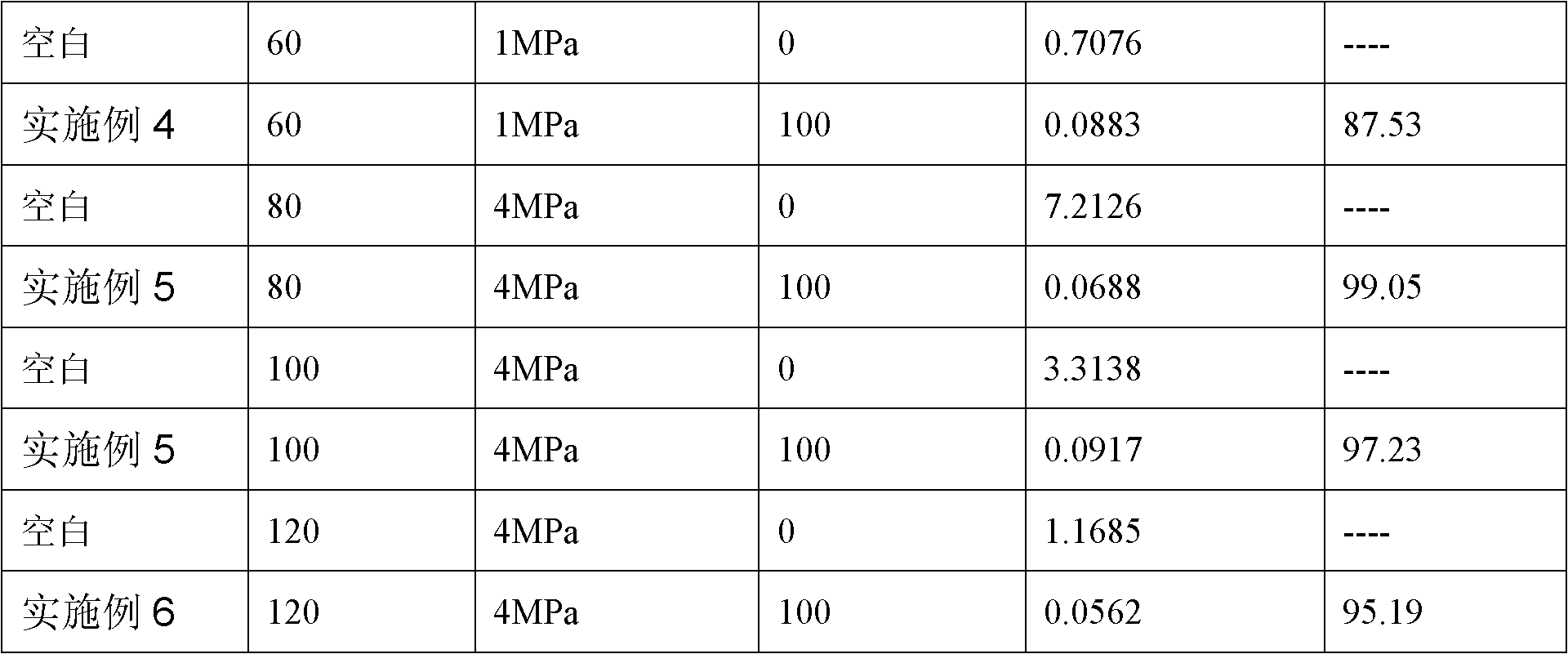

Examples

Embodiment 1

[0036] This example is used to prepare corrosive media.

[0037] Add 2 grams of sodium bicarbonate, 0.3 g of sodium sulfate, 0.2 g of calcium chloride, 0.2 g of magnesium chloride, and 13 g of sodium chloride into 1000 g of water, and stir to completely dissolve the sodium chloride to obtain a 3.0% by weight sodium chloride solution as a corrosive medium.

Embodiment 2

[0039] This example is used to prepare thioimidazolone derivatives

[0040] Put 120g of ethylenediamine and 40g of ethanol into a 500ml reaction kettle, and slowly add 160g of carbon disulfide dropwise at room temperature under the conditions of reflux condensation and stirring. After completion, turn on the power, heat to 60°C, and reflux for 10 hours. The obtained product was cooled in an ice bath, and the precipitate was washed with acetone to obtain a thioimidazolone derivative.

Embodiment 3

[0042] This example is used to prepare thioalkyl quaternary ammonium salt

[0043] Put 120g of octadecylamine, 50g of ethanol, and 60g of benzyl chloride into a 500ml reaction kettle. Under the condition of reflux condensation and stirring, react at 100°C for 4 hours, cool down, add 70g of ethanol solvent and stir, after cooling The product obtained is the alkyl quaternary ammonium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com