Compounded carbon dioxide corrosion inhibitor

A technology of carbon dioxide and corrosion inhibitor, which is applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of oil field production economic loss, environmental pollution, high perforation rate, etc., to reduce consumption, prevent corrosion, and improve corrosion inhibition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Compound the corrosion inhibitor with other substances according to the formula in Table 1. The listed percentages are all mass percentages, and the balance is distilled water. Among them, the corrosion inhibitor A can be obtained by using oleic acid and diethylenetriamine as raw materials, through intermolecular amidation and intramolecular cyclodehydration. Concrete reaction equation is as follows:

[0016] Wang Xia, Shangguan Changhuai, Hu Zhiqiang. Evaluation of corrosion inhibition performance of 2-aminoethyl heptadecenyl imidazoline[J]. Fine Petrochemical Industry, 2010,27(1):39.

[0017]

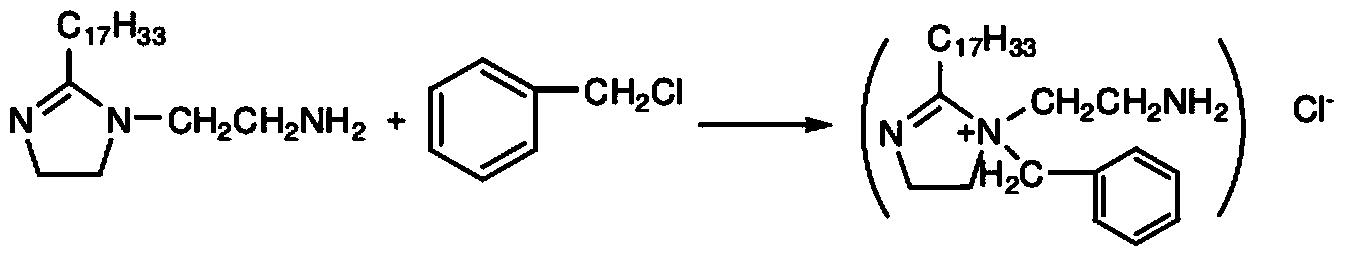

[0018] R is for C 17 h 33 ; Corrosion inhibitor A and benzyl chloride are quaternized to obtain corrosion inhibitor B. Concrete reaction equation is as follows:

[0019]

[0020] Table 1 Combination of compound corrosion inhibitors

[0021]

Embodiment 2

[0023] Corrosion test: The material used in the test is Q235 steel, and its chemical composition (%, w) is C0.17, Si0.20, Mn0.45, P0.01, S0.03, and Fe balance. The size of the test piece is 50mm×10mm×3mm. Use analytical reagent and distilled water to prepare 12 parts of NaCl solution with a mass fraction of 3.5%. The first part is a blank solution without adding any corrosion inhibitor; the second to fifth parts are respectively added with 50mg / L corrosion inhibitors A~D; Add 50mg / L composite corrosion inhibitor a~g to 7 parts respectively.

[0024] Scrub the test piece with decontamination powder first, rinse it with distilled water, then wash it with acetone and absolute ethanol, dry it with hot air and weigh it, hang the steel piece in the above 12 solutions respectively, and pass through 1h CO 2 The solution was saturated and the experimental temperature was 60 °C. After soaking for 72 hours, take the test piece out, soak it in the post-treatment solution for 3 minutes, ...

Embodiment 3

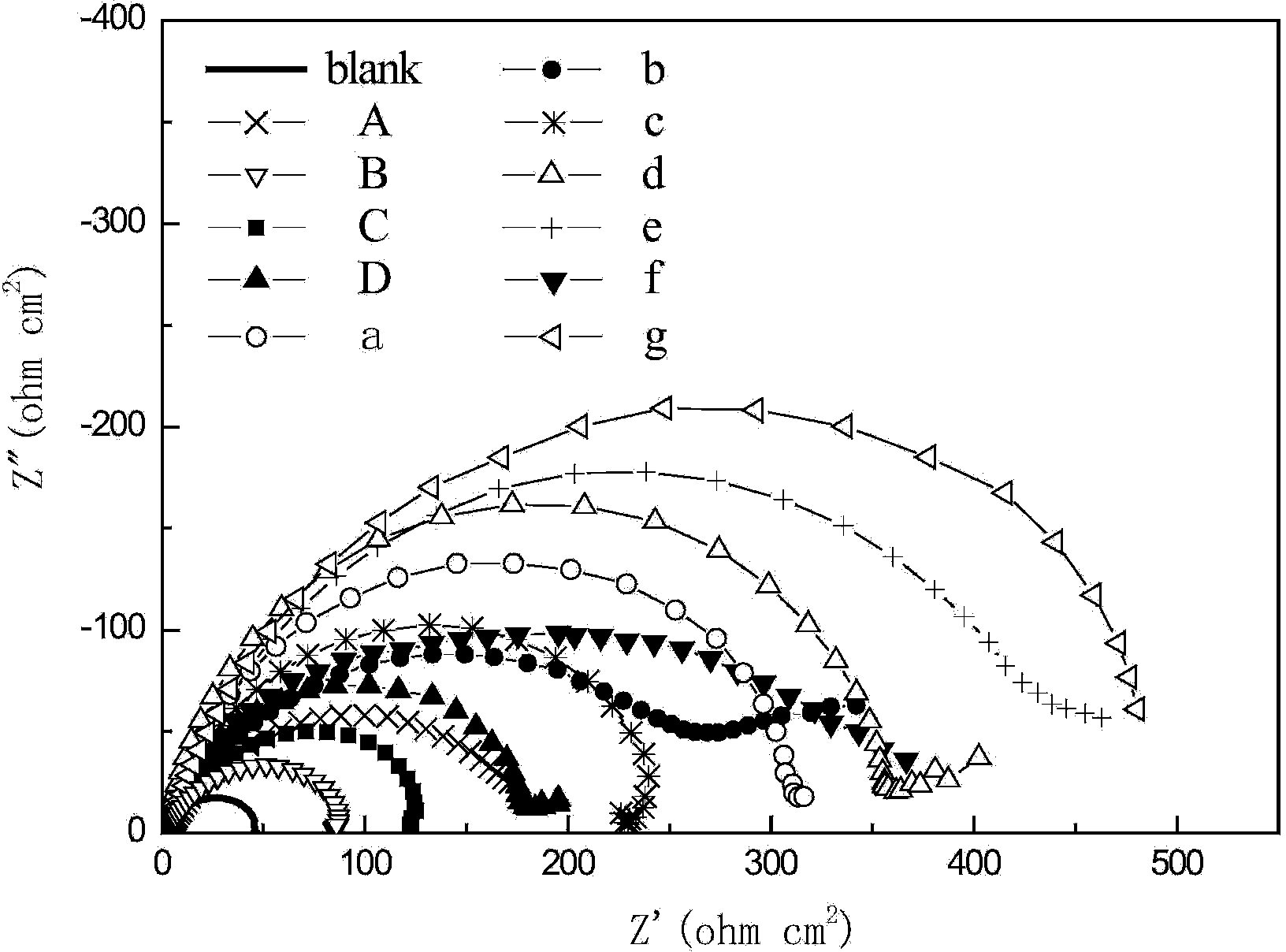

[0029] Use analytical reagent and distilled water to prepare 12 parts of NaCl solution with a mass fraction of 3.5%. The first part is a blank solution without adding any corrosion inhibitor; the second to fifth parts are respectively added with 50mg / L corrosion inhibitors A~D; Add 50mg / L composite corrosion inhibitor a~g to 7 parts respectively.

[0030] Electrochemical impedance test: The traditional three-electrode system is adopted, the working electrode material is Q235 steel, the auxiliary electrode is a platinum electrode, and the reference electrode is a saturated calomel electrode (SCE). The perturbation potential amplitude of electrochemical impedance spectroscopy is ±5mV, scanning from high frequency to low frequency, and the scanning frequency range is 100kHz-0.01Hz. The electrochemical impedance test parameters are shown in Table 3:

[0031] Table 3: CO Added with Different Corrosion Inhibitors 2 N measured in saturated brine y quist spectrum fitting parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com