Pipeline steel resistant to carbon dioxide corrosion and preparation method thereof

A technology of carbon dioxide and pipeline steel, which is applied in the field of pipeline steel and its manufacturing, can solve the problems of early corrosion failure, rare corrosion-resistant carbon dioxide corrosion-resistant materials, pipeline pitting and perforation, etc., and achieve good comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

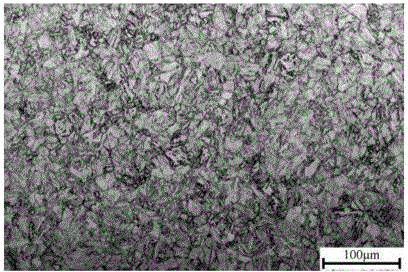

Image

Examples

specific Embodiment

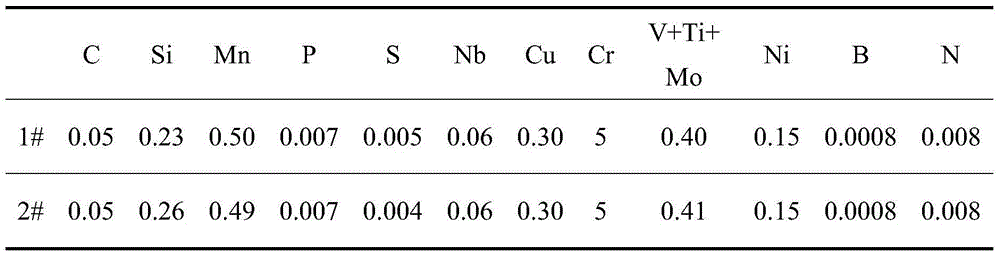

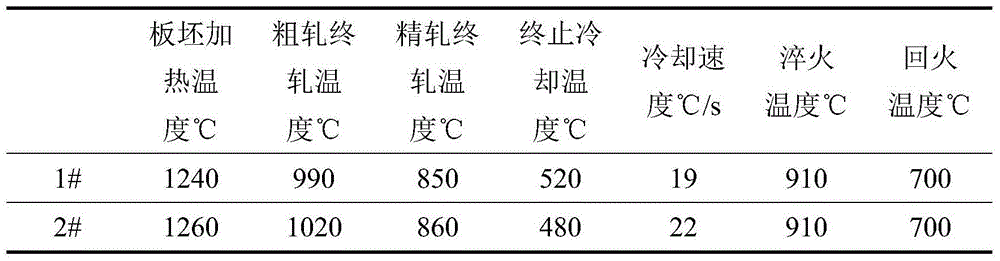

[0054] See Table 1-1 for the chemical composition mass ratios of the carbon dioxide corrosion-resistant pipeline steel examples, and the specific implementation methods of the examples include the following steps:

[0055] The first step is to smelt and cast steel billets according to the above composition and put them into the heat preservation pit to cool slowly to room temperature;

[0056] The second step, heating: the billet is heated at 1100°C to 1250°C, and kept for 2 to 3 hours to ensure the uniformity of the temperature and structure of the billet;

[0057] The third step, rough rolling: the rough rolling temperature is guaranteed to be between 940-1100°C, and the cumulative reduction rate is 65-75%;

[0058] The fourth step, finish rolling: the finish rolling temperature is guaranteed to be between 800-920°C, and the cumulative reduction rate is 60-70%;

[0059] The fifth step, cooling: the cooling rate is 10-30°C / s, and the final cooling temperature is in the range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com