Method for predicting corrosion degree of natural gas pipeline under gas-liquid two-phase flow

A technology for natural gas pipelines and prediction methods, which is applied in the field of prediction of corrosion degree of natural gas pipelines under gas-liquid two-phase flow, and can solve problems such as corrosion, reduction of medium flow rate, and increased consumption of power and energy for pipeline transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a method for predicting the corrosion degree of a natural gas pipeline under gas-liquid two-phase flow, including the following steps:

[0024] Step 1) Collect natural gas pipeline operating condition information, including temperature, pressure, medium composition, gas-liquid ratio, carbon dioxide content, and flow rate of each phase;

[0025] Step 2) establish the momentum equation, energy equation, and mass equation of each component, and establish the gas-liquid two-phase fluid model of the natural gas pipeline;

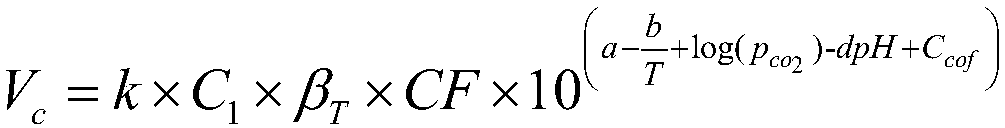

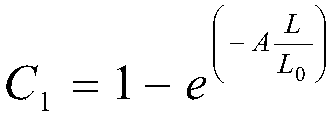

[0026] Step 3) Based on the gas-liquid two-phase fluid model of the natural gas pipeline, on the basis of the collection and analysis of the working condition information of the natural gas pipeline, through modeling, the numerical simulation of the two-phase flow flow pattern and flow state change of the fluid in the pipeline is carried out to obtain the pipeline section Temperature, pressure, carbon dioxide partial pressure, flow...

Embodiment 2

[0029] On the basis of Example 1, this example provides a method for predicting the corrosion degree of a gas-liquid two-phase flow natural gas pipeline, and the specific steps are as follows:

[0030] Step 1) Collect natural gas pipeline operating condition information, including temperature, pressure, medium composition, gas-liquid ratio, carbon dioxide content, and flow rate of each phase;

[0031] Step 2) According to the theory of fluid mechanics and the state of motion involved in the two-phase flow of natural gas pipelines, the gas-liquid two-phase fluid model of natural gas pipelines is established by theoretical analysis. The models include momentum, energy, and mass models, and the momentum conservation equations, energy conservation equations, and Mass conservation equations and mass transfer models;

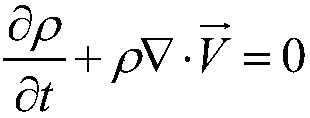

[0032] (1) Establish mass conservation equation (continuity equation):

[0033]

[0034] In the formula, ρ is the fluid density, V is the fluid velocity, Tensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com