Rod blockage prevention liquid for carbon dioxide huff-puff enhanced oil recovery and injection method thereof

A technology of carbon dioxide and enhanced oil recovery, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of wax deposition on the inner wall of oil pipes, affecting production, polluting formations, etc., and achieves low price, simple method, The effect of reducing the sticking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The following components are prepared according to the mass percentage ratio of the anti-stick liquid: 40% ethylene glycol, 3% carbon dioxide corrosion inhibitor, 5% anti-swelling agent, 2% anti-scaling agent, 2% surfactant, and the balance is water, and mix the components evenly to prepare the anti-stick liquid.

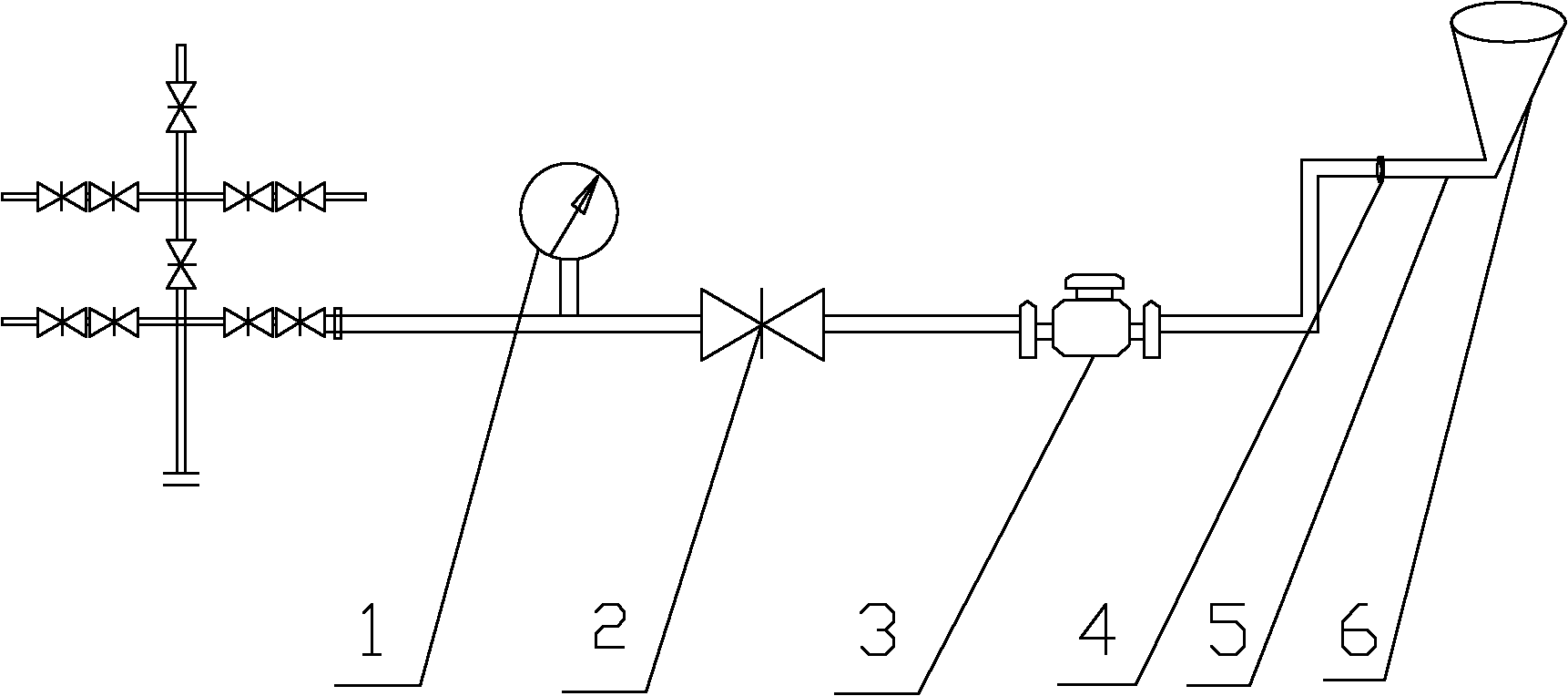

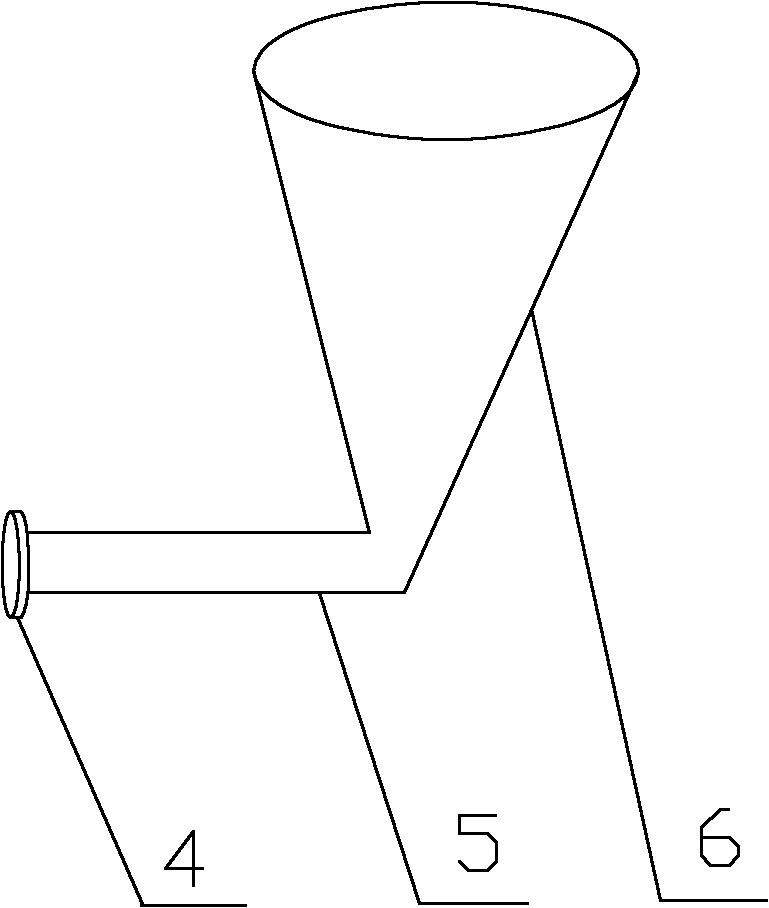

[0023] like figure 1 , figure 2 As shown, first open the wellhead casing gate to vent the casing gas; install pressure gauge 1, check valve 2, valve 3, and chemical inflow device at the wellhead casing mouth, and the two ends of valve 3 are fixed and sealed by clamps and clamp pieces , a pressure gauge is installed to observe the bottom-hole pressure to prevent the bottom-hole pressure from being too large; the above-mentioned anti-rod sticking liquid of the prepared medicine is added into the medicine inflow device, and the structure of the medicine inflow device is that the upper part is a dosing funnel 6 , the bottom opening of the dosing funnel 6 is r...

Embodiment 2

[0025] The following components are prepared in the proportioning ratio of the following components to prevent sticking liquid: 50% ethylene glycol, 5% carbon dioxide corrosion inhibitor, 5% anti-swelling agent, 2% anti-scaling agent, and 2% surfactant. Divide and mix evenly to prepare anti-rod stuck liquid.

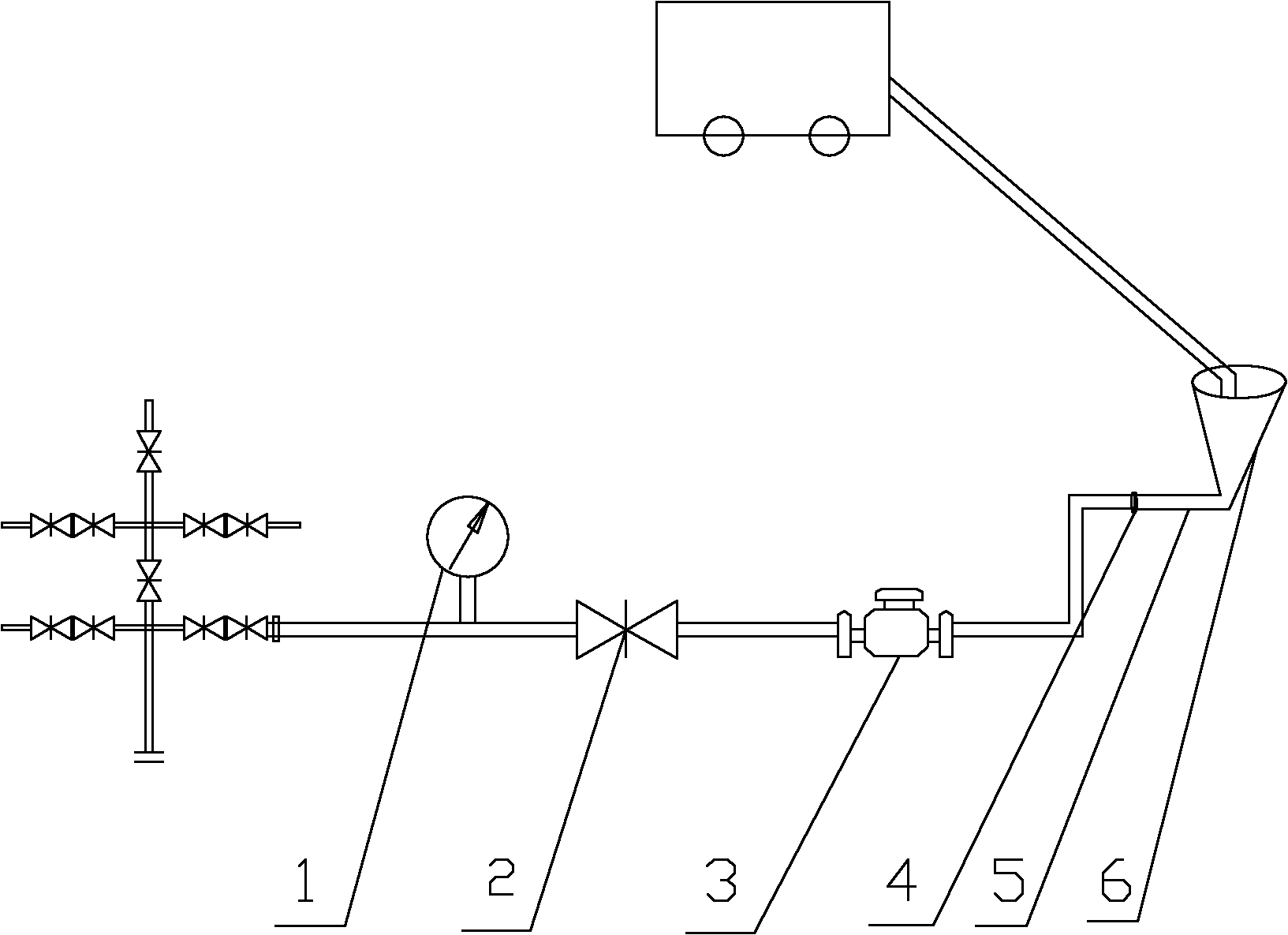

[0026] First, open the wellhead casing gate to vent the casing gas; install a pressure gauge, a check valve, a valve, and a chemical inflow device at the wellhead casing mouth, and the two ends of the valve are fixed and sealed by clamps and clamp pieces; image 3 As shown, use a tank truck to transport the medicine, put the liquid outlet of the tank truck into the inflow device, and add the above prepared medicine anti-rod jam liquid into the medicine inflow device through the liquid outlet of the tank car, during the process of filling the medicine The medium pumping unit does not stop. When a large amount of anti-rod jam fluid appears at the wellhead, stop the pumping...

Embodiment 3

[0028] The following components are proportioned according to mass percentage to prepare the anti-stick liquid: 45% ethylene glycol, 4% carbon dioxide corrosion inhibitor, 5% anti-swelling agent, 2% anti-scaling agent, 2% surfactant, and the balance is water, and mix the components evenly to prepare the anti-stick liquid.

[0029] First, open the wellhead casing gate to vent the casing gas; install a pressure gauge, a check valve, a valve, and a chemical inflow device at the wellhead casing port, and the two ends of the valve are fixed and sealed by clamps and clamp pieces; Add the anti-rod jam fluid into the agent inflow device, and the pumping unit does not stop during the injection process. When a large amount of anti-rod jam fluid appears at the wellhead, stop the pumping unit at the bottom dead center; then remove the device for injecting the agent, Close the wellhead casing.

[0030] All the compounds used in the above examples are commercially available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com