A fuel cell power generation system using liquid hydrogen as fuel

A fuel cell and liquid hydrogen technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problem that liquid hydrogen cannot be directly used for power generation by fuel cells, and achieve the effects of light weight, compact structure, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

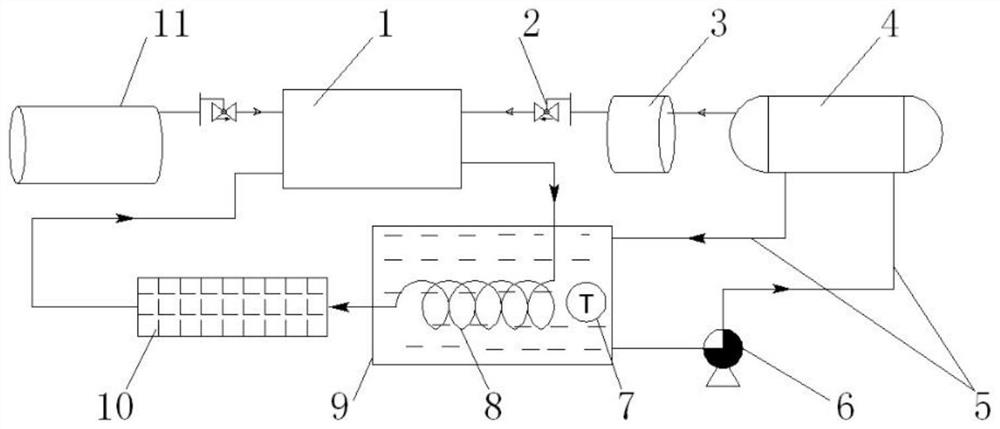

[0019] A schematic flow chart of Embodiment 1 of a fuel cell power generation system using liquid hydrogen as fuel is shown in figure 1 Shown: This process is applicable to the proton exchange membrane fuel cell system of static drainage technology. This embodiment mainly considers the characteristics of the static drainage technology of the fuel cell, separates the thermal management of the fuel cell itself from the thermal management of the liquid hydrogen system, and uses a heat exchanger to realize the excess of thermal energy.

[0020] combine figure 1 , the present invention is composed of a fuel cell module 1, a control valve 2 (such as a solenoid valve), a buffer tank 3, a liquid hydrogen storage tank 4, a circulating water pipeline 5, a circulating water pump 6, a monitoring unit 7, a heat exchanger 8, and a water tank 9, radiator 10, oxygen supply system 11 composition.

[0021] The fuel cell module 1, the heat exchanger 8 and the radiator 10 constitute a thermal m...

Embodiment 2

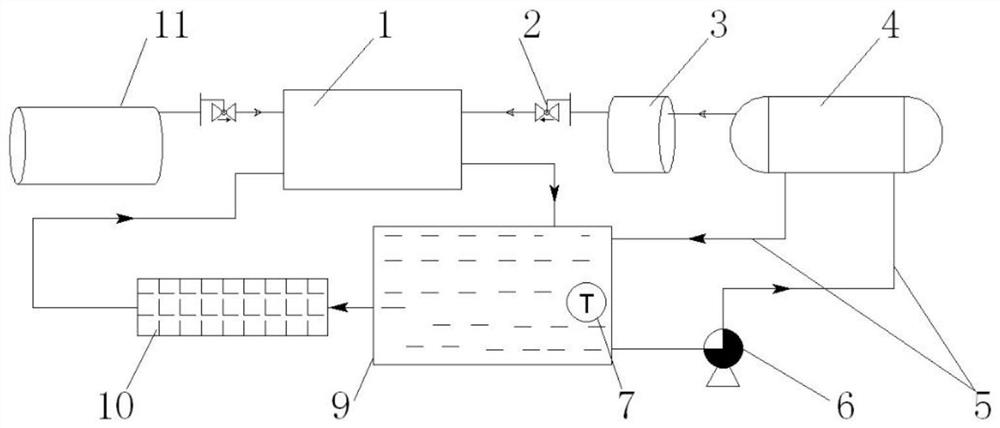

[0026] A schematic flow chart of Embodiment 2 of a fuel cell power generation system using liquid hydrogen as fuel is shown in figure 2 Shown: This process is applicable to the proton exchange membrane fuel cell system with dynamic drainage technology. Considering the own characteristics of the fuel cell dynamic water drainage technology, combining the fuel cell’s own heat management waterway with the liquid hydrogen system’s heat management waterway, the system will omit the heat exchanger 8 in Embodiment 1, and all water circulation lines are at normal pressure Pipeline, the system is simpler. The specific implementation steps are as follows:

[0027] combine figure 2 , the present invention is composed of a fuel cell module 1, a control valve 2 (such as a solenoid valve), a buffer tank 3, a liquid hydrogen storage tank 4, a circulating water pipeline 5, a circulating water pump 6, a monitoring unit 7, a water tank 9, and a radiator 10 , The oxygen supply system 11 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com