Carbon dioxide corrosion resisting cement system for oil-gas well cementation

A carbon dioxide, well cementing technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of increasing the risk and cost of cementing operations, shortening the thickening time of cement systems, and poor anti-pollution performance of high-alumina cement, etc. problems, to achieve good resistance to Portland cement pollution, excellent CO2 corrosion resistance, and improve the effect of cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

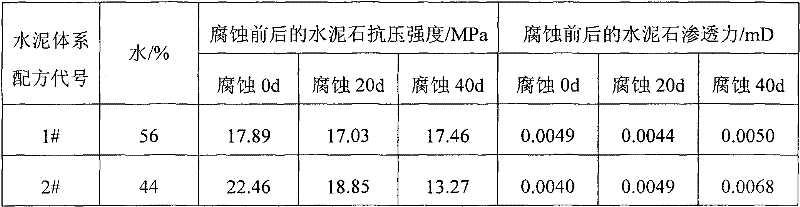

[0023] Embodiment 1, the corrosion resistance performance evaluation of the carbon dioxide corrosion resistant cement system for oil and gas well cementing of the present invention

[0024] The formula of the carbon dioxide corrosion-resistant cement system for oil and gas well cementing of the present invention: aluminophosphate cement, 15% sodium hexametaphosphate, 3.25% sodium tetraborate, and 9% bentonite. The code name is 1#.

[0025] Portland cement-based carbon dioxide corrosion-resistant cement system formula: Jiahua G grade cement, 8% silica fume, 1% fluid loss reducer JS-2 (polyvinyl alcohol), 1% dispersant SWJZ-1 ( aldehydes and ketones). Code-named 2# for comparison.

[0026] Prepare cement slurry according to GB / T 19139-2003 standard for oil well cement test methods, wherein water and other components in the cement system formula are respectively proportioned by mass percentage based on the total weight of aluminophosphate cement or Jiahua G grade; Then pour th...

Embodiment 2

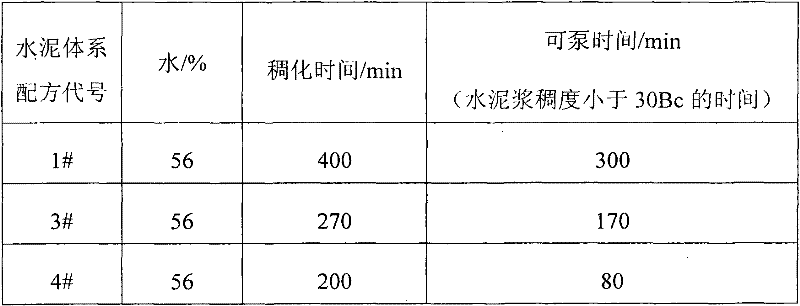

[0029] Example 2, the anti-pollution performance evaluation of the carbon dioxide corrosion-resistant cement system for oil and gas well cementing of the present invention

[0030] 1# cement system formula: aluminophosphate cement, 15% sodium hexametaphosphate, 3.25% sodium tetraborate, 9% bentonite.

[0031] 3# cement system formula: add 5% of Jiahua G-grade Portland cement (proportioned by mass percentage based on the total weight of aluminophosphate cement) on the basis of the 1# cement system formula.

[0032] 4# cement system formula: Add 10% of Jiahua G-grade Portland cement (proportioned by mass percentage based on the total weight of aluminophosphate cement) on the basis of the 1# cement system formula.

[0033] Prepare cement slurry according to GB / T 19139-2003 standard for oil well cement test methods, in which water is proportioned by mass percentage based on the total weight of aluminophosphate cement. Test 1#, 3# and 4# cement system formulations at 75 ° C , Thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com