Method for determining corrosion rate of natural gas injection and production well pipe column under erosion-carbon dioxide corrosion coupling action

A technology of corrosion rate and carbon dioxide, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of little discussion and inapplicability of electrochemical corrosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

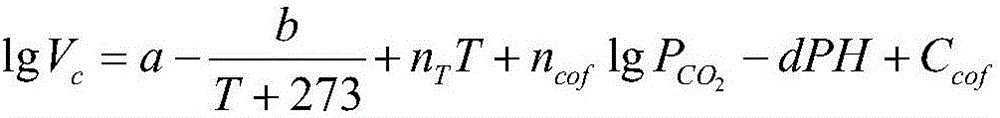

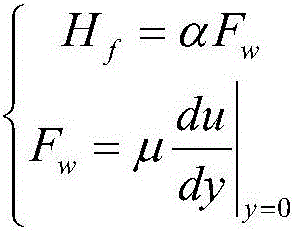

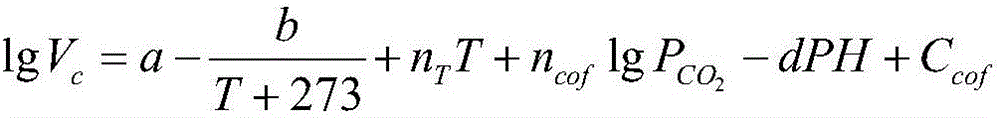

[0027] Example 1: A method for determining the corrosion rate of a natural gas injection-production well pipe string under the coupled action of erosion-carbon dioxide corrosion. First, based on the theory of fluid mechanics and the state of motion involved in natural gas injection and production, a mathematical model of the flow field is established using a theoretical analysis method ; then according to the carbon dioxide corrosion theory, on the basis of detailed analysis of the natural gas well corrosion data, the carbon dioxide corrosion model is established; then according to the carbon dioxide corrosion theory, on the basis of the detailed analysis of the natural gas well corrosion data, the carbon dioxide corrosion model is established; finally the above The model is written into a user-defined function and imported into commercial software for simulation calculation. The inventive method comprises the steps:

[0028] Step 1: According to the theory of fluid mechanics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com