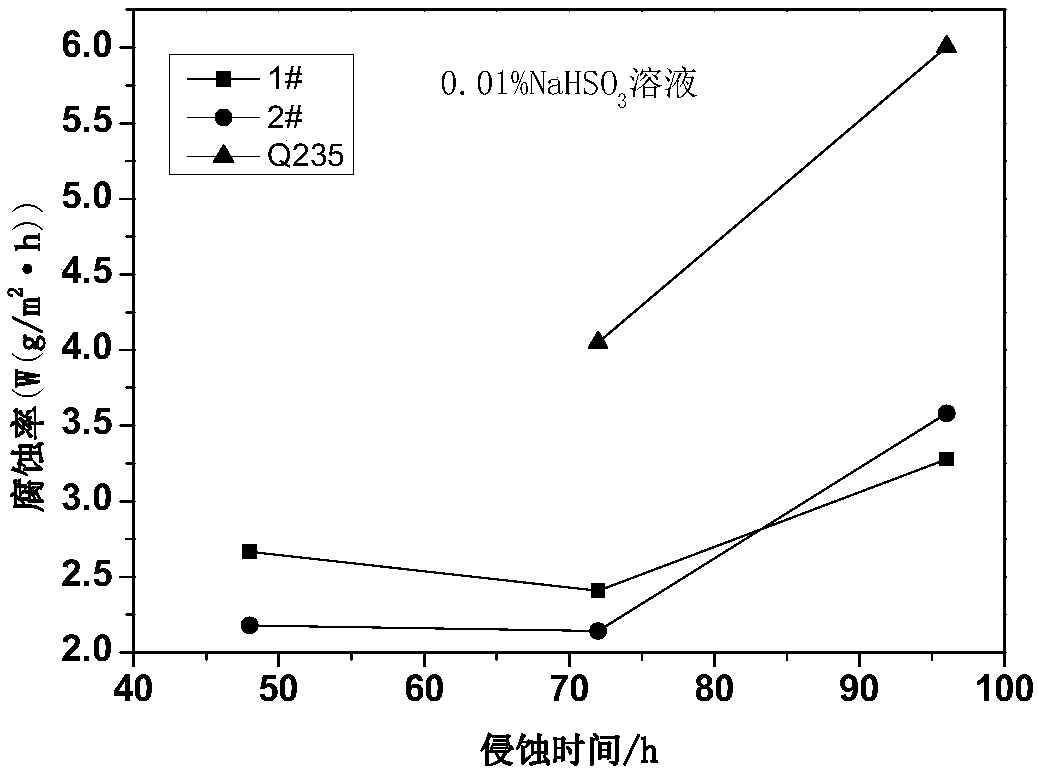

Industrial atmospheric corrosion resistant steel bar and preparation method thereof

An atmospheric corrosion and corrosion-resistant technology, applied in the field of industrial atmospheric corrosion-resistant steel bars, can solve the problems of unsatisfactory anti-corrosion effect, difficult construction and high cost, and achieve the effect of good industrial general corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical route adopted in the present invention: 70-ton ultra-high-power electric furnace—LF ladle refining—tapping deoxidation alloying—argon blowing treatment—4 machines, 4 streams, 165 billet continuous casting—regenerative walking heating furnace—18 racks Twist-free tandem rolling unit—water cooling—finishing—packing—storage.

[0035] (1) Adopt electric furnace hot charging molten iron process, the proportion of molten iron and scrap steel is 50%, energize and melt, strengthen oxygen supply and decarburization, control the slagging process, dephosphorize, remove harmful impurities in steel, and reach the tapping condition (molten steel temperature: 1630~1650℃), slag-free tapping at the eccentric furnace bottom, and alloying in the ladle. According to the calculated alloy addition amount, add low-carbon ferrochrome, copper plate, molybdenum iron, nickel plate, vanadium nitrogen, phosphorus ferro, into the ladle in advance, and during the tapping process of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| carbon equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com