Nickeling liquid and nickeling method for metal-matrix composite

A technology of composite materials and metal materials, applied in the field of nickel plating solution and nickel plating, can solve the problem of low corrosion resistance of the film, and achieve the effect of good combination and simple and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Embodiment 1: In this embodiment, the nickel plating solution per liter of metal matrix composite material consists of 0.1-0.5 mol of NiSO 4 ·6H 2 O, 0.01-0.1mol of NiCl 2 ·6H 2 O, 0.02-0.10mol of H 3 PO 4 , 0.05~0.2mol of H 3 PO 3 , 0.01~0.05mol of C 6 h 8 o 7 ·H 2 O and the balance of water.

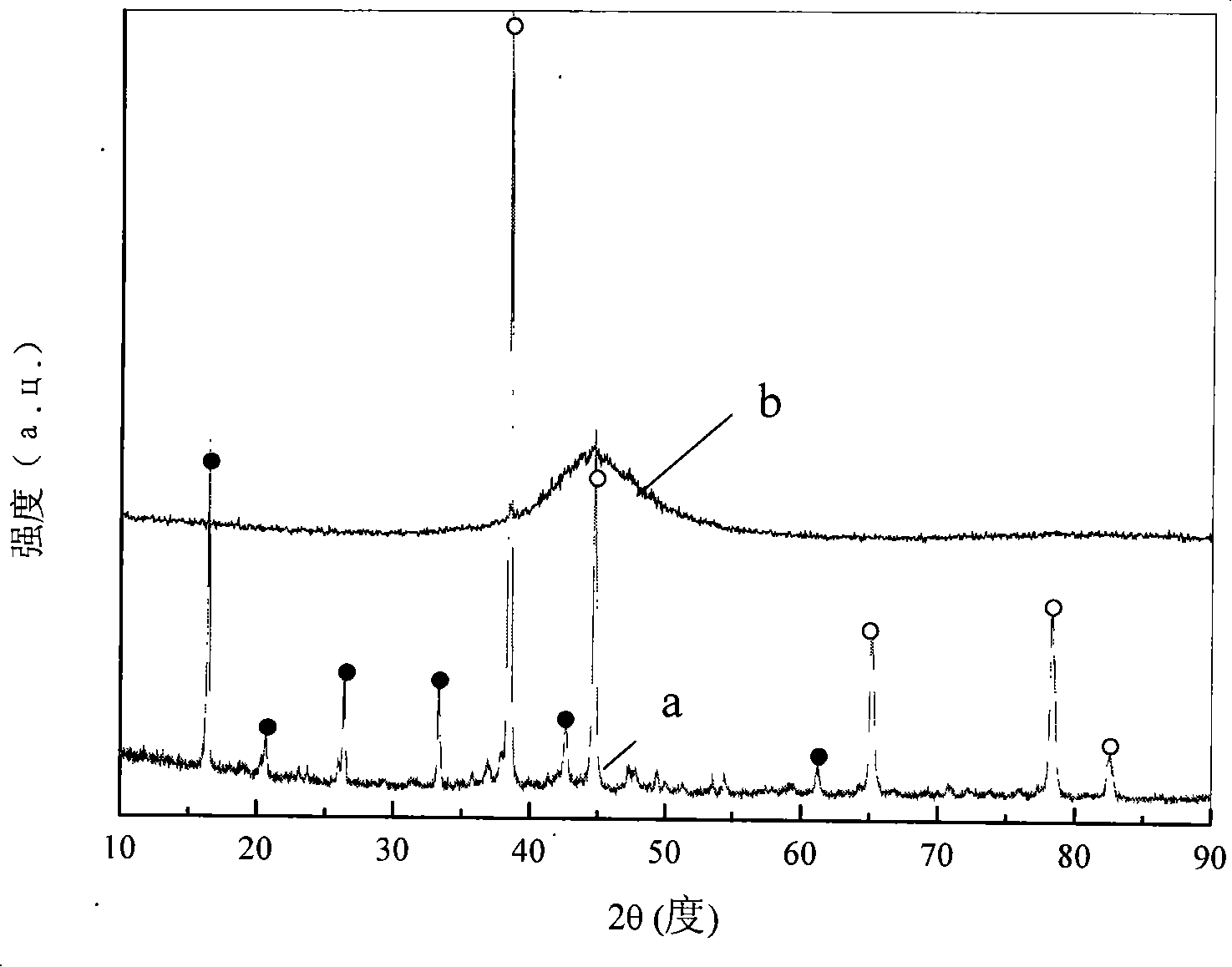

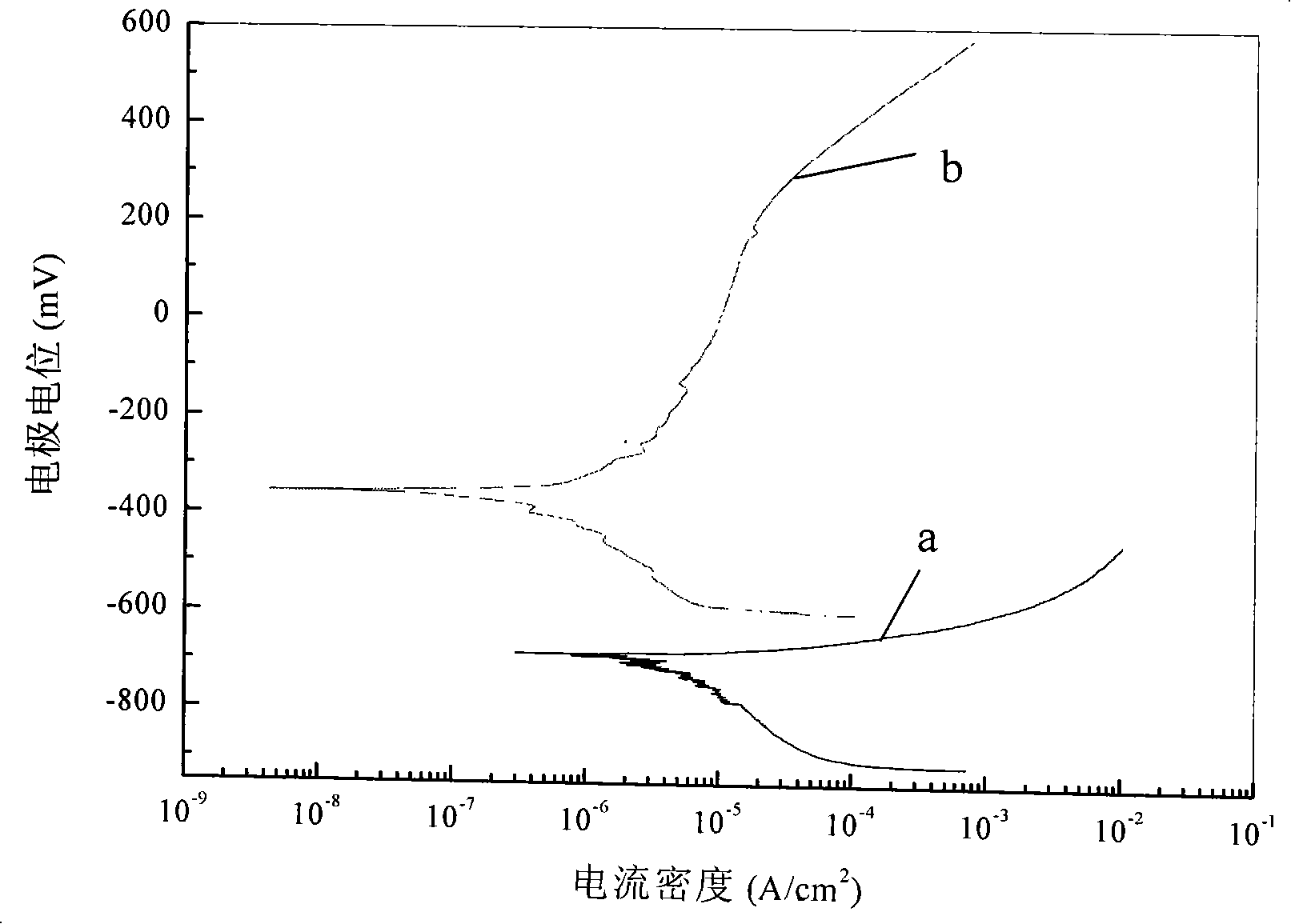

[0010] The metal matrix composite material in this embodiment adopts Al with a diameter of 1-10 μm and a length of 10-30 μm. 18 B 4 o 33 Whiskers are reinforcements. The chemical composition (mass%) is: 2024 aluminum alloy with 4.4% Cu, 1.5% Mg, 0.5% Mn, 0.5% Si and less than 0.5% Fe as the base. Al with a volume fraction of about 20% was prepared by squeeze casting 18 B 4 o 33 / 2024Al composite. At a current density of 1000A / m 2 , the solution pH value is 2, under the condition of 55 ℃, use NiSO 4 ·6H 2 The concentration of O is 0.46mol / L, NiCl 2 ·6H 2 O concentration is 0.08mol / L, H 3 PO 4 The concentration is 0.08mol / L, H 3 PO 3 Plating solution wit...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the nickel plating solution per liter of metal matrix composite material consists of 0.15-0.2 mol of NiSO 4 ·6H 2 O, 0.02-0.04mol of NiCl 2 ·6H 2 O, 0.03-0.05mol of H 3 PO 4 , 0.06~0.09mol of H 3 PO 3 , 0.015~0.02mol of C 6 h 8 o 7 ·H 2 O and the balance of water. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the nickel plating solution per liter of metal matrix composite material consists of 0.25-0.3 mol of NiSO 4 ·6H 2 O, 0.05-0.09mol of NiCl 2 ·6H 2 O, 0.06-0.09mol of H 3 PO 4 , 0.1~0.19mol of H 3 PO 3 , 0.03~0.04mol of C 6 h 8 o 7 ·H 2 O and the balance of water. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com