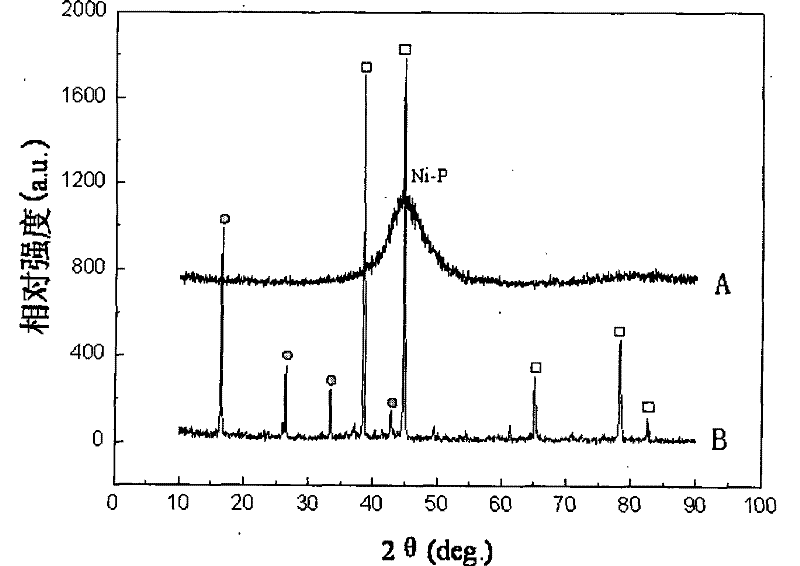

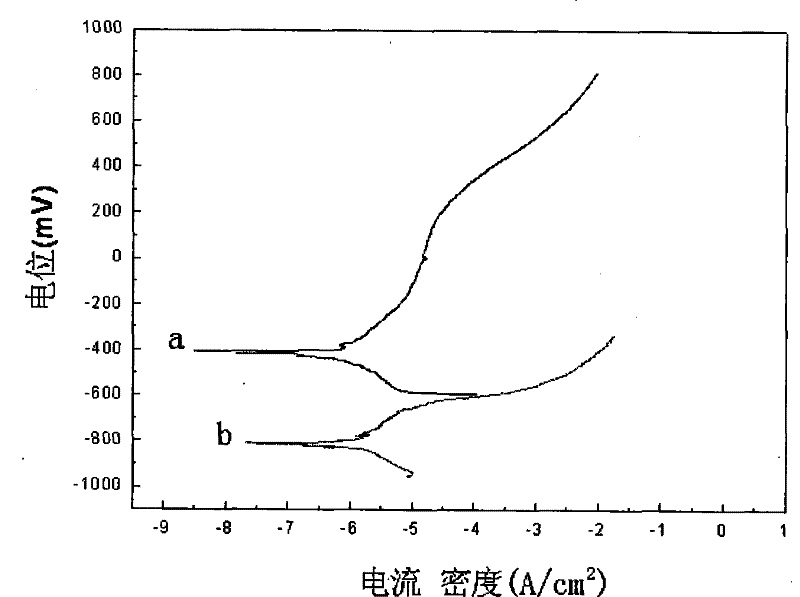

Surface plating Ni-P layer method for improving corrosion resistance of metal-matrix composite material

A technology of composite materials and surface chemistry, which is applied in the field of chemical plating on the surface of metal matrix composite materials, can solve the problems of low bonding strength between the coating and the metal substrate, pretreatment process of coating easy to fall off, uneven coating thickness, etc., and achieve high bonding strength , uniform thickness, and reduced corrosion current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific Embodiment 1: In this embodiment, the method for electroless plating Ni-P layer on the surface of the metal matrix composite material to improve the corrosion resistance is realized by the following steps: 1. Pre-grinding the metal matrix composite material to a surface roughness of 0.01-10 μm, Then place it in absolute ethanol for ultrasonic cleaning for 1-5 minutes, then rinse it with deionized water for 10-30 seconds, and then place it in acetone for ultrasonic cleaning for 1-5 minutes, then rinse it with deionized water for 10-30 seconds; The metal matrix composite material is placed in a NaOH solution with a concentration of 0.5-3mol / L for 1-180s, then ultrasonically cleaned in deionized water for 10-30s, and then placed in an electroless plating solution at 60-100°C After dipping for 1-120min, the electroless Ni-P layer on the surface of the metal matrix composite material is completed; the electroless plating solution in step 2 consists of 0.057-0.152mol / ...

specific Embodiment approach 2

[0010] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the metal matrix composite material is pre-grinded to a surface roughness of 0.05-8 μm, and then ultrasonically cleaned in absolute ethanol for 2-4 minutes. Rinse again with deionized water for 15-25s, place in acetone for ultrasonic cleaning for 2-4min after rinsing, and then rinse with deionized water for 15-25s. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 1, the metal matrix composite material is pre-grinded to a surface roughness of 0.1-6 μm, and then ultrasonically cleaned in absolute ethanol for 2.5-3.5 minutes , and then rinsed with deionized water for 18-22s, and then placed in acetone for ultrasonic cleaning for 2.5-3.5min, and then rinsed with deionized water for 18-22s. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com