High-performance steel plate resistant to corrosion of marine total immersion zone and production method of high-performance steel plate

A production method and high-performance technology, applied in the field of metal materials, can solve the problems of poor low-temperature impact toughness, small thickness specification of steel plate, biological corrosion, etc., and achieve the effect of stable corrosion performance, large thickness specification range, and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

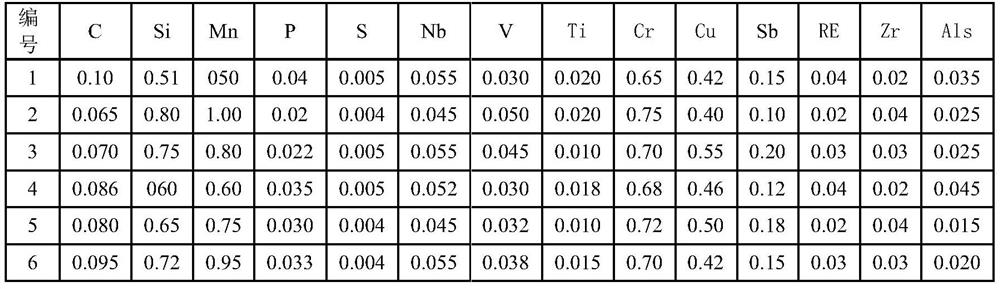

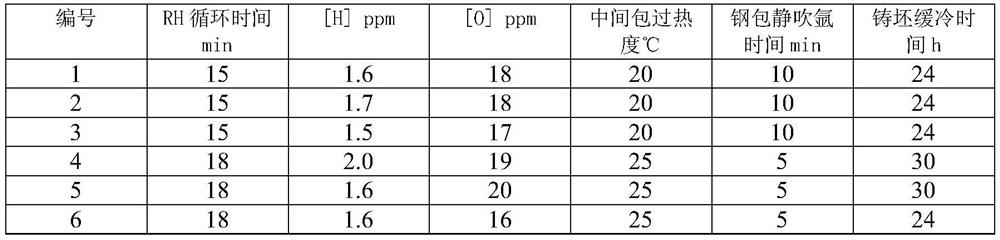

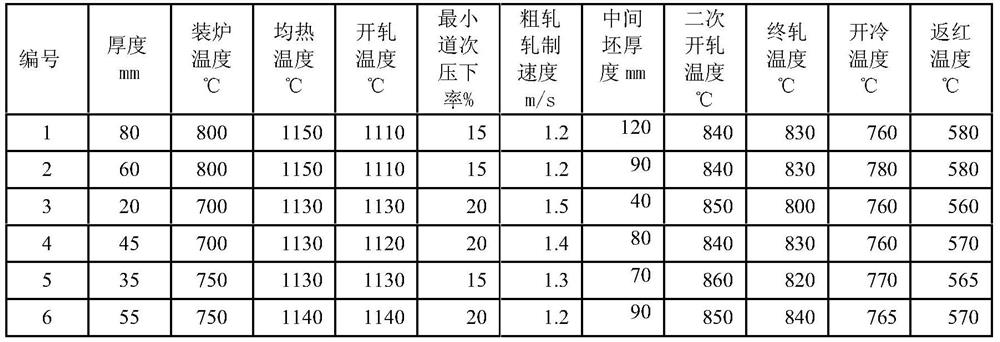

[0038] According to the above-mentioned chemical composition and production process, the actual smelting composition of the present invention is shown in Table 1, the actual smelting and continuous casting process parameters of the present invention are shown in Table 2, the rolling process parameters are shown in Table 3, and the physical properties are shown in Table 4.

[0039] Table 1 Smelting composition, Wt%

[0040]

[0041] Table 2 Smelting and continuous casting process parameters

[0042]

[0043] Table 3 rolling process parameters

[0044]

[0045] Table 4 physical properties

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com