Method for employing copper-steel composite board to prevent adhesion corrosion of marine organisms and preparation method for copper-steel composite board

A technology of marine organisms and composite boards, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of difficult construction and high cost of copper shell protection, and achieve anti-fouling bio-adhesion and excellent atmospheric resistance and seawater corrosion performance, the effect of low toxicity to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

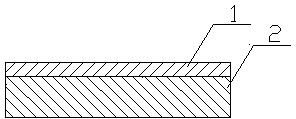

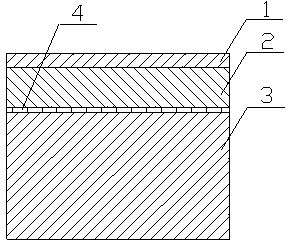

[0044] refer to figure 1 , figure 2 , using copper / steel composite boards to prevent marine organisms from attaching and corroding, using copper / steel composite boards to wrap the outer shell of the facility 3 to be protected; the copper / steel composite boards include an outer copper cladding layer 1 and a steel plate layer 2, The metallurgical bond between the steel plate layer 2 and the outer copper cladding layer 1, wherein the steel plate layer 2 is attached to the facility 3 to be protected. Usually, a welding method can be used to realize the connection of the steel plate layer 2 and the facility 3 to be protected, so as to form the weld 4 , of course, other methods can also be used.

[0045] The preparation method of above-mentioned copper / steel clad plate, main steps are as Figure 5 mentioned, specifically:

[0046] ①. Surface roughening: roughen one surface of the outer copper cladding layer and one surface of the steel plate layer,

[0047] Make the surface ro...

Embodiment 2

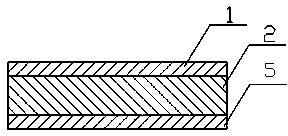

[0056] refer to image 3 , Figure 4 , using copper / steel / copper composite board to wrap the outer shell of the facility 3 that needs to be protected; the copper / steel / copper composite board includes an outer copper cladding layer 1, an inner copper cladding layer 5, and a steel plate layer 2, and the steel plate Layer 2 is sandwiched between the outer copper cladding layer 1 and the inner copper cladding layer 5, between the steel plate layer 2 and the outer copper cladding layer 1, and between the steel plate layer 2 and the inner copper cladding layer 5 Metallurgical bonding.

[0057] The preparation method of above-mentioned copper / steel / copper clad plate, main steps are as Figure 5 mentioned, specifically:

[0058] ①. Surface roughening: one surface of the outer copper cladding, one surface of the inner copper cladding and two sides of the steel plate

[0059] Texture treatment is carried out on each surface, so that the surface roughness Rz of the outer copper clad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com