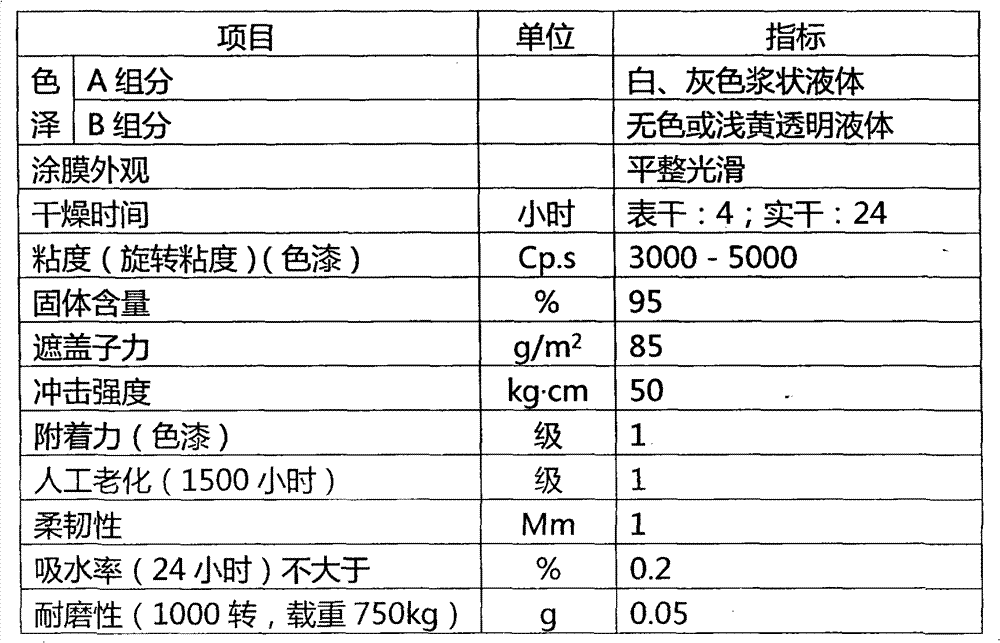

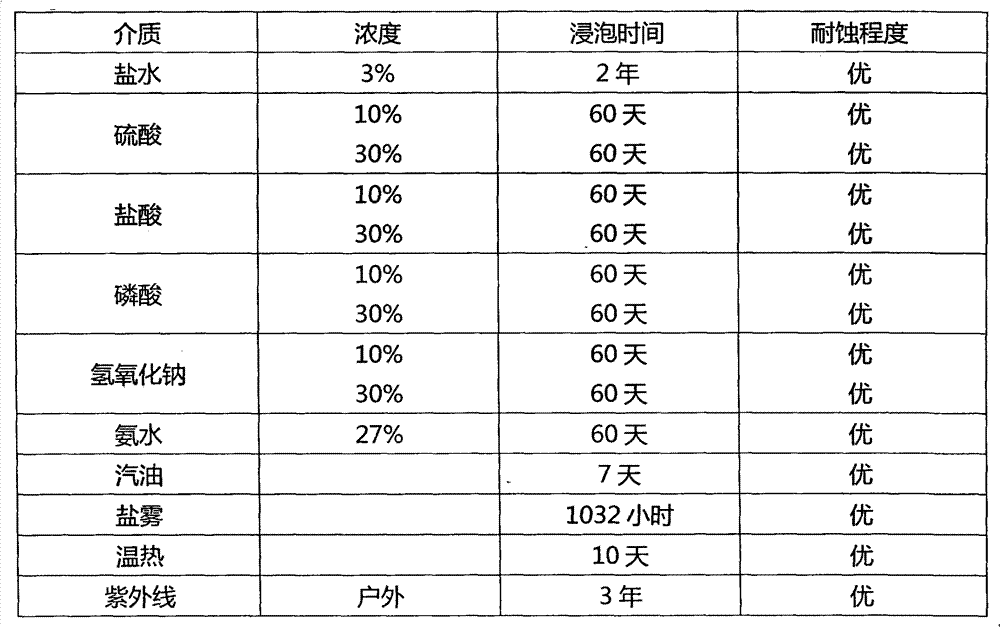

GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating and its preparation method

A 1. GZ-12, epoxy coating technology, applied in the field of coatings, can solve problems such as unfavorable, affecting the health of officers and soldiers, and improving combat effectiveness, and achieve the effect of simple construction, fast drying, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

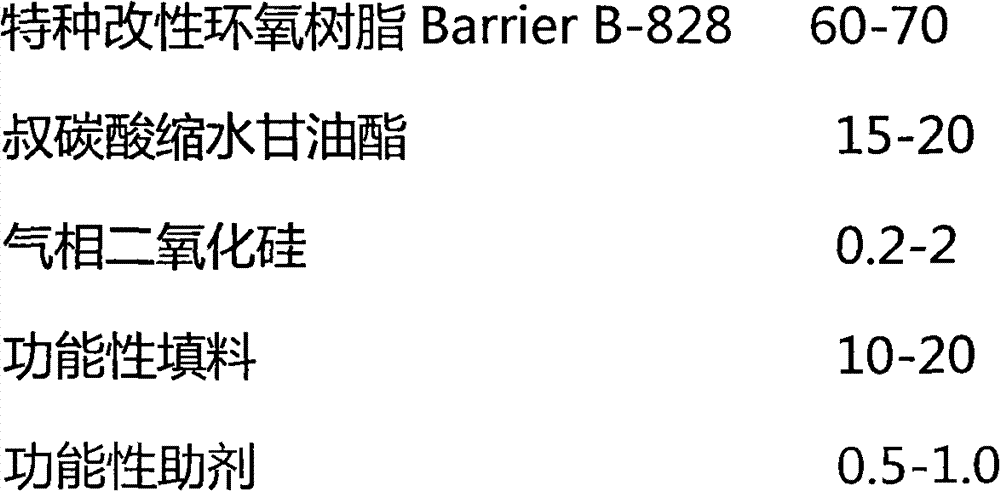

Embodiment 1

[0030] 1) Synthesize Barrier B-828 resin, react epichlorohydrin, unsaturated monomer unsaturated organic acid, and metal drier in a four-necked flask according to the proportion, control the reaction temperature at 110-120 degrees, until the acid value drops to The reaction is completed below 12mgKOH / g, and Barrier B-828 special modified epoxy resin is obtained;

[0031] 2) Pre-disperse the resin, glycidyl tert-carbonic acid ester, functional additives, etc. according to the ratio at a speed of 650-750 rpm, and make it uniform for 20-40 minutes;

[0032] 3) Put the functional filler into the above stock solution according to the proportion, and then disperse at a high speed of 1200-1400 rpm for 60-90 minutes;

[0033] 4) Toning;

[0034] 5) Routine inspection;

[0035] 6) Filtration, filter the qualified paint with a 50-100 μm filter or a 160-mesh metal screen, and pack it separately to obtain the component A product of the present invention.

[0036] The weight ratio of co...

Embodiment 2

[0038] 1) Synthesize Barrier B-828 resin, react epichlorohydrin, unsaturated monomer unsaturated organic acid, and metal drier in a four-necked flask according to the proportion, control the reaction temperature at 110-120 degrees, until the acid value drops to Finish the reaction below 15mgKOH / g to obtain Barrier B-828 special modified epoxy resin;

[0039] 2) Pre-disperse the resin, glycidyl tert-carbonic acid ester, functional additives, etc. according to the ratio at a speed of 650-750 rpm, and make it uniform for 20-40 minutes;

[0040] 3) Put the functional filler into the above stock solution according to the proportion, and then disperse at a high speed of 1200-1400 rpm for 60-90 minutes;

[0041] 4) Toning;

[0042] 5) Routine inspection;

[0043] 6) Filtration, filter the qualified paint with a 50-100 μm filter or a 160-mesh metal screen, and pack it separately to obtain the component A product of the present invention.

[0044] The weight ratio of component A to ...

Embodiment 3

[0046] 1) Synthesize Barrier B-828 resin, react epichlorohydrin, unsaturated monomer unsaturated organic acid, and metal drier in a four-necked flask according to the proportion, control the reaction temperature at 110-120 degrees, until the acid value drops to The reaction is completed below 20mgKOH / g, and Barrier B-828 special modified epoxy resin is obtained;

[0047] 2) Pre-disperse the resin, glycidyl tert-carbonic acid ester, functional additives, etc. according to the ratio at a speed of 650-750 rpm, and make it uniform for 20-40 minutes;

[0048] 3) Put the functional filler into the above stock solution according to the proportion, and then disperse at a high speed of 1200-1400 rpm for 60-90 minutes;

[0049] 4) Toning;

[0050] 5) Routine inspection;

[0051] 6) Filtration, filter the qualified paint with a 50-100 μm filter or a 160-mesh metal screen, and pack it separately to obtain the component A product of the present invention.

[0052] The weight ratio of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com