Degradable biomedical Mg-Zn-Zr-Nd alloy material and preparation method thereof

A biomedical and alloy material technology, applied in medical science, surgery, etc., can solve the problems of fast corrosion rate of magnesium alloy, insufficient mechanical properties, and no consideration of material biocompatibility, etc., to achieve good mechanical properties and processing properties, preparation The method is simple and avoids the effect of premature failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

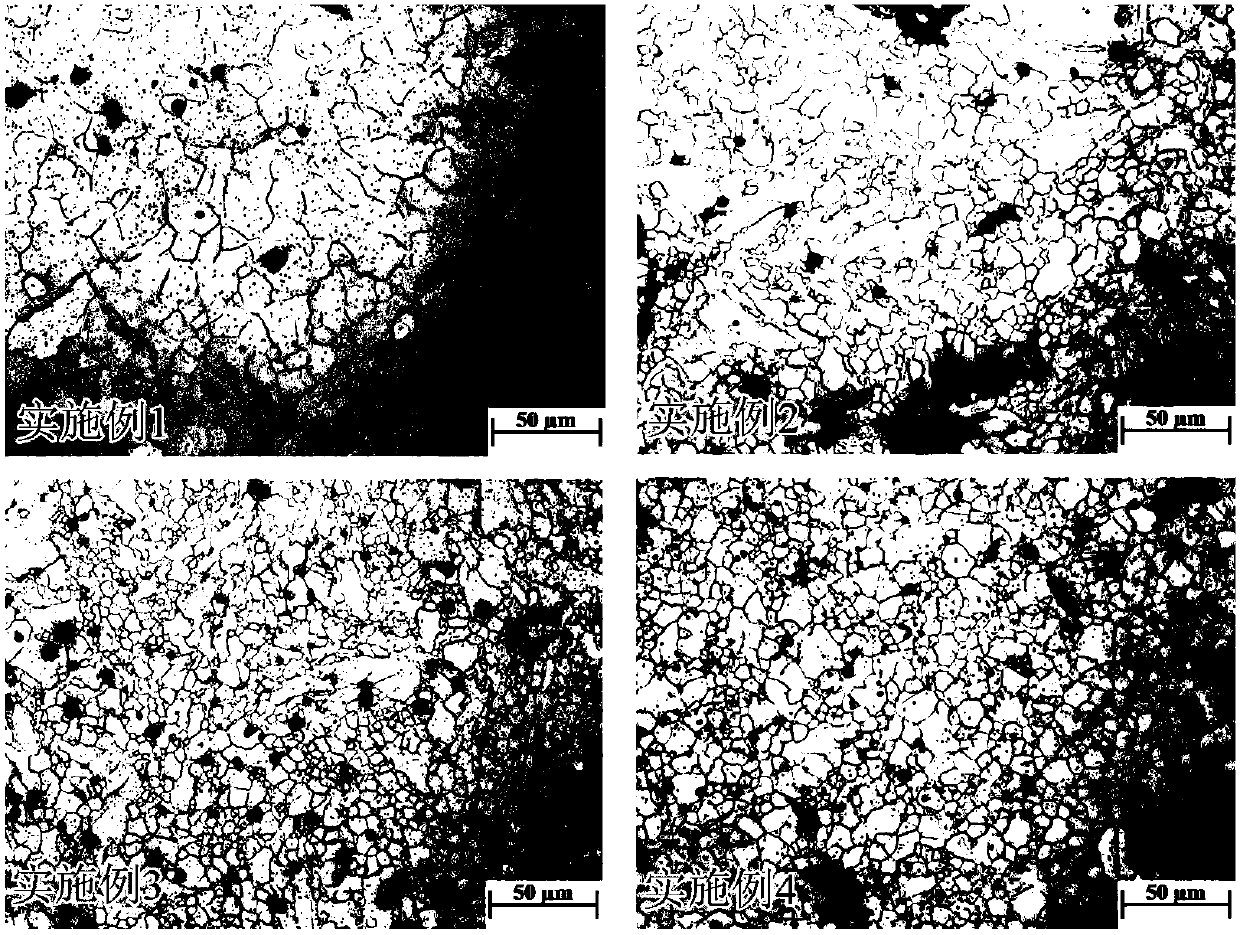

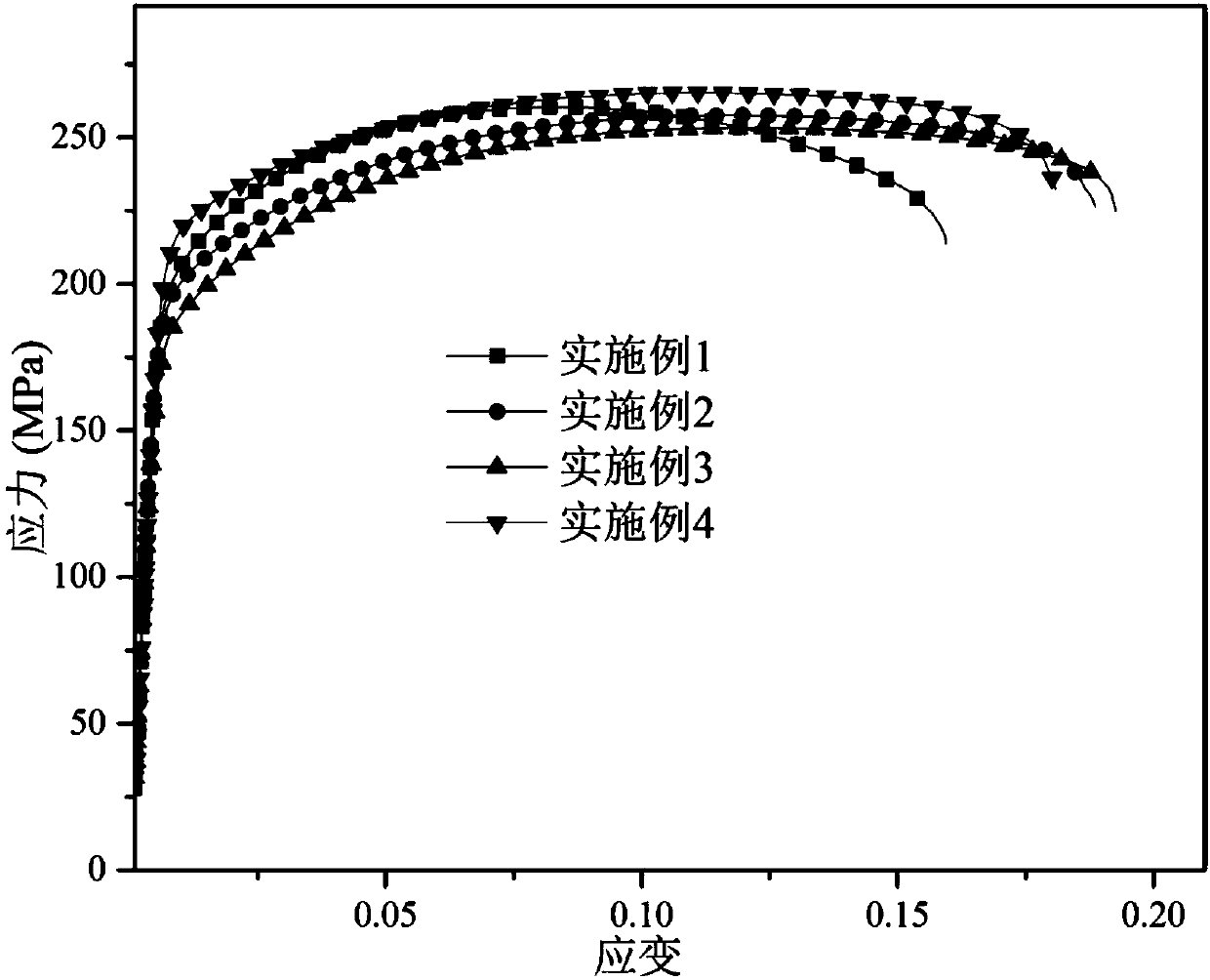

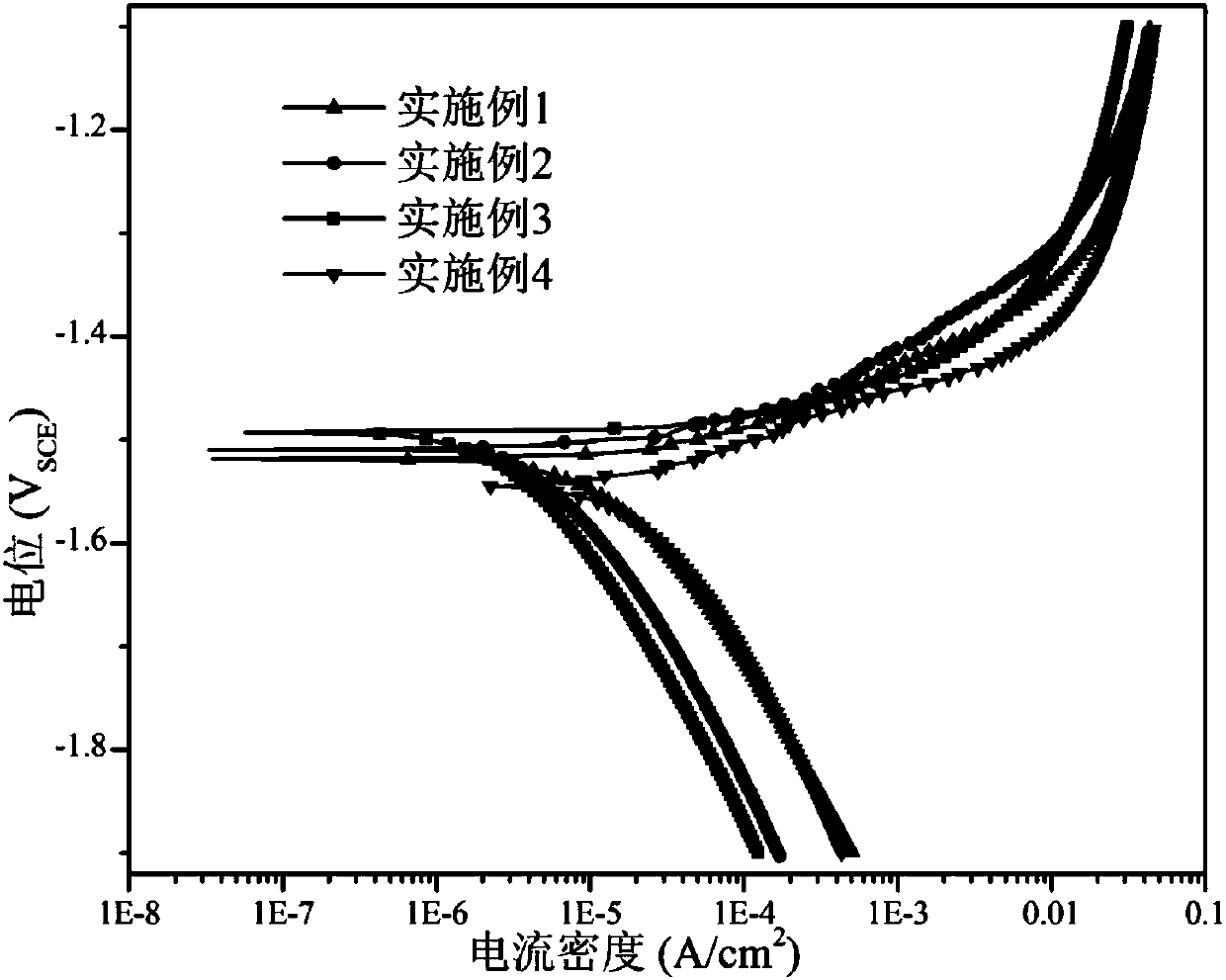

Embodiment 1

[0024] The degradable biomedical Mg-Zn-Zr-Nd alloy material in this example is prepared from the following components according to the mass percentage: Zn 1.8%, Zr 0.6%, Nd 0.1%, and the rest are Mg and unavoidable impurity elements .

[0025] Concrete preparation steps are as follows:

[0026] (1) Weigh the raw materials according to the proportioning ratio. The above-mentioned raw materials adopt high-purity magnesium alloy (Mg≥99.99%), high-purity zinc ingot (Zn≥99.995%), Mg-30% Zr master alloy (Zr: 29.6%, impurity content 0.008%, The balance is Mg) and Mg-30% Nd master alloy (Nd: 29.2%, the impurity content is 0.005%, and the balance is Mg). The above raw materials are smelted in a vacuum induction furnace under the protection of argon, and kept at 780°C 20 minutes, after the above raw materials are all melted, stir for 2 minutes, then cool down to 740°C and refine for 8 minutes, after refining, raise the temperature to 750°C and let it stand for 6 minutes, and cast it in...

Embodiment 2

[0031] The degradable biomedical Mg-Zn-Zr-Nd alloy material in this example is prepared from the following components according to the mass percentage: Zn 2.0%, Zr 0.5%, Nd 0.3%, and the rest are Mg and unavoidable impurity elements .

[0032] Concrete preparation steps are as follows:

[0033] (1) Weigh the raw materials according to the proportioning ratio. The above-mentioned raw materials adopt high-purity magnesium alloy (Mg≥99.99%), high-purity zinc ingot (Zn≥99.995%), Mg-30% Zr master alloy (Zr: 29.6%, impurity content 0.008%, The balance is Mg) and Mg-30% Nd master alloy (Nd: 29.2%, the impurity content is 0.005%, and the balance is Mg). The above raw materials are smelted in a vacuum induction furnace under the protection of argon, and kept at 780°C 20 minutes, after the above raw materials are all melted, stir for 2 minutes, then cool down to 740°C and refine for 8 minutes, after refining, raise the temperature to 750°C and let it stand for 6 minutes, and cast it in...

Embodiment 3

[0038] The degradable biomedical Mg-Zn-Zr-Nd alloy material in this example is prepared from the following components according to the mass percentage: Zn 1.9%, Zr 0.6%, Nd 0.7%, and the rest are Mg and unavoidable impurity elements .

[0039] Concrete preparation steps are as follows:

[0040] (1) Weigh the raw materials according to the proportioning ratio. The above-mentioned raw materials adopt high-purity magnesium alloy (Mg≥99.99%), high-purity zinc ingot (Zn≥99.995%), Mg-30% Zr master alloy (Zr: 29.6%, impurity content 0.008%, The balance is Mg) and Mg-30% Nd master alloy (Nd: 29.2%, the impurity content is 0.005%, and the balance is Mg). The above raw materials are smelted in a vacuum induction furnace under the protection of argon, and kept at 790°C 25min, after the above raw materials are melted, stir for 3min, then cool down to 750°C and refine for 10min, after refining, raise the temperature to 760°C and let stand for 8min, then cast into ingot at 720°C;

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com