Preparation method of corrosion-resistant Cr3C2-NiCr-aluminum-silicon siloxane composite coating on surface of crystallizer copper plate

A crystallizer copper plate and composite coating technology, which is applied to the surface coating liquid device, coating, metal material coating process, etc., can solve the problems of poor corrosion resistance, high porosity, etc., to improve corrosion performance, The effect of high density and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

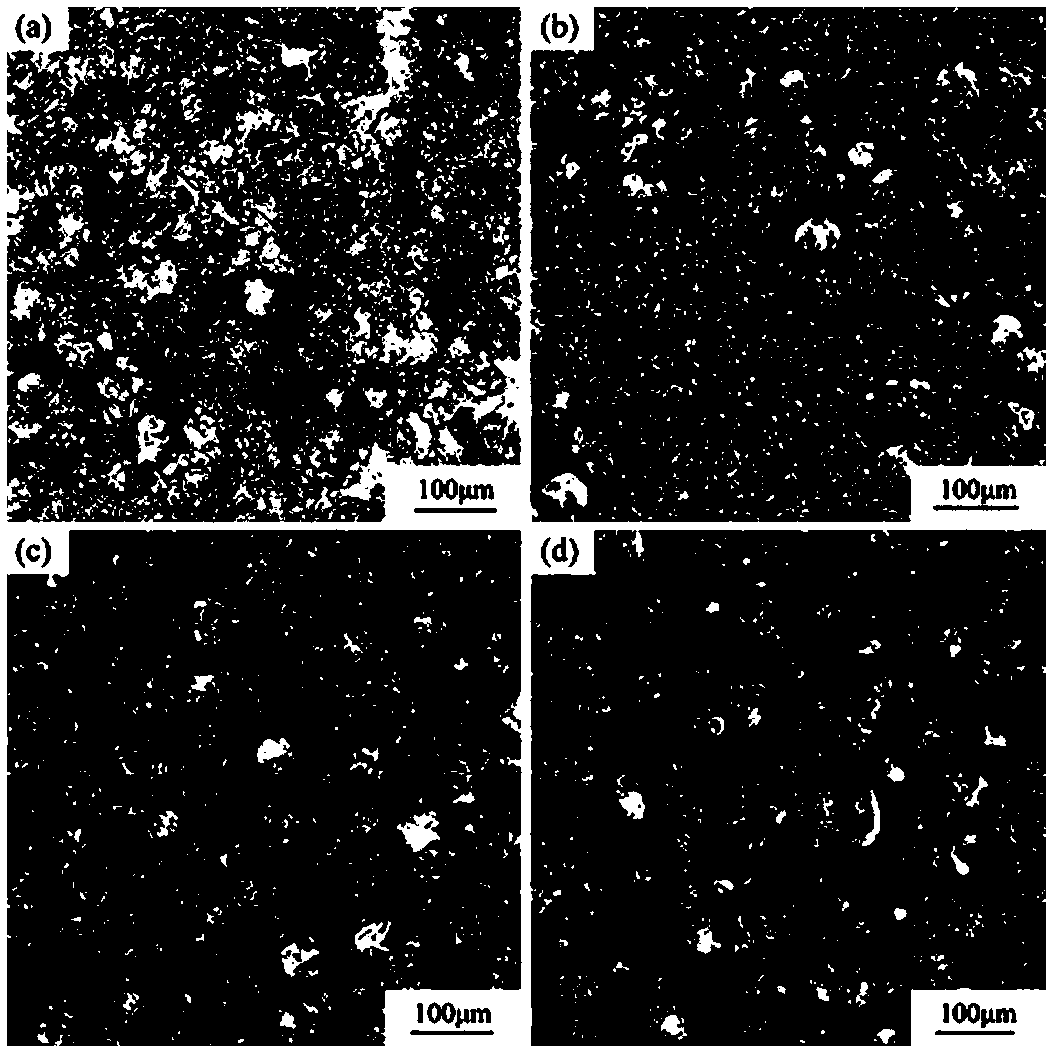

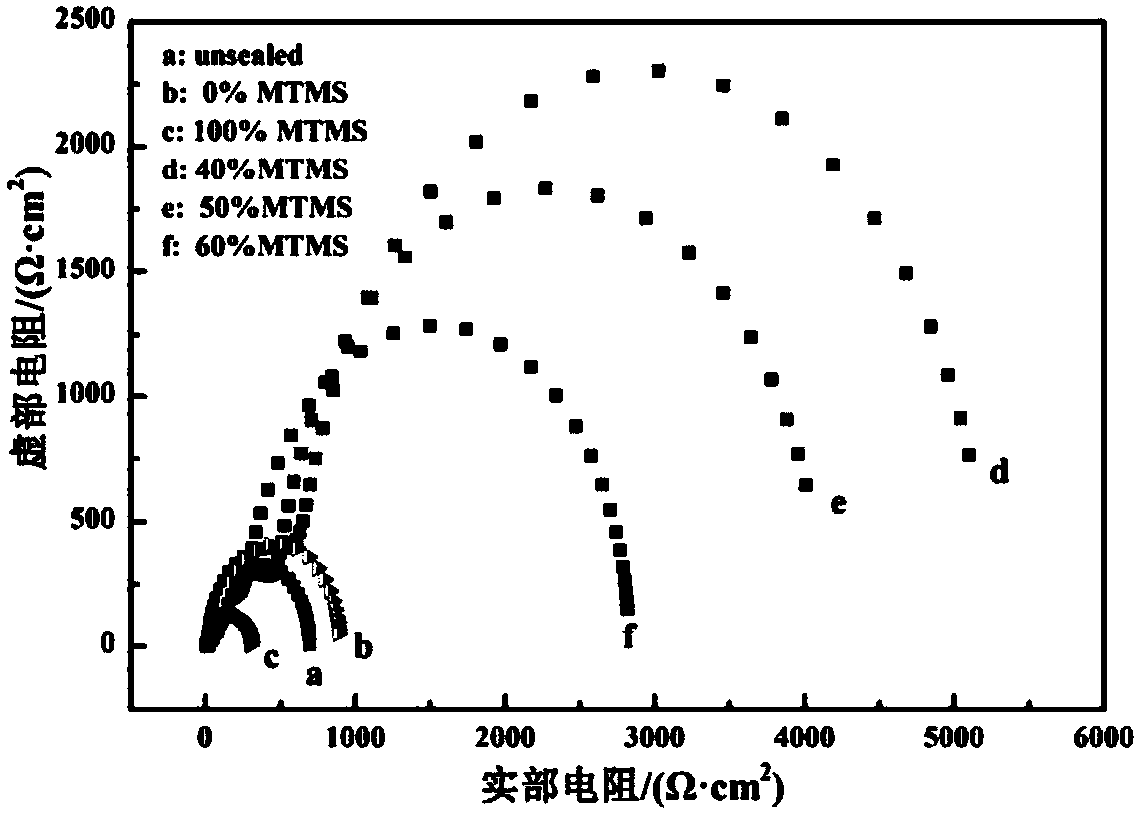

[0017] (1) First use supersonic flame spraying (HVOF or HVAF) to prepare Cr 3 C 2 -NiCr layer, mix aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane (MTMS) according to the mass ratio: 100:66.7 and stir for 4 to 6 hours to prepare aluminum-silicon composite sol (pH﹤1) and Methyltrimethoxysilane mixture.

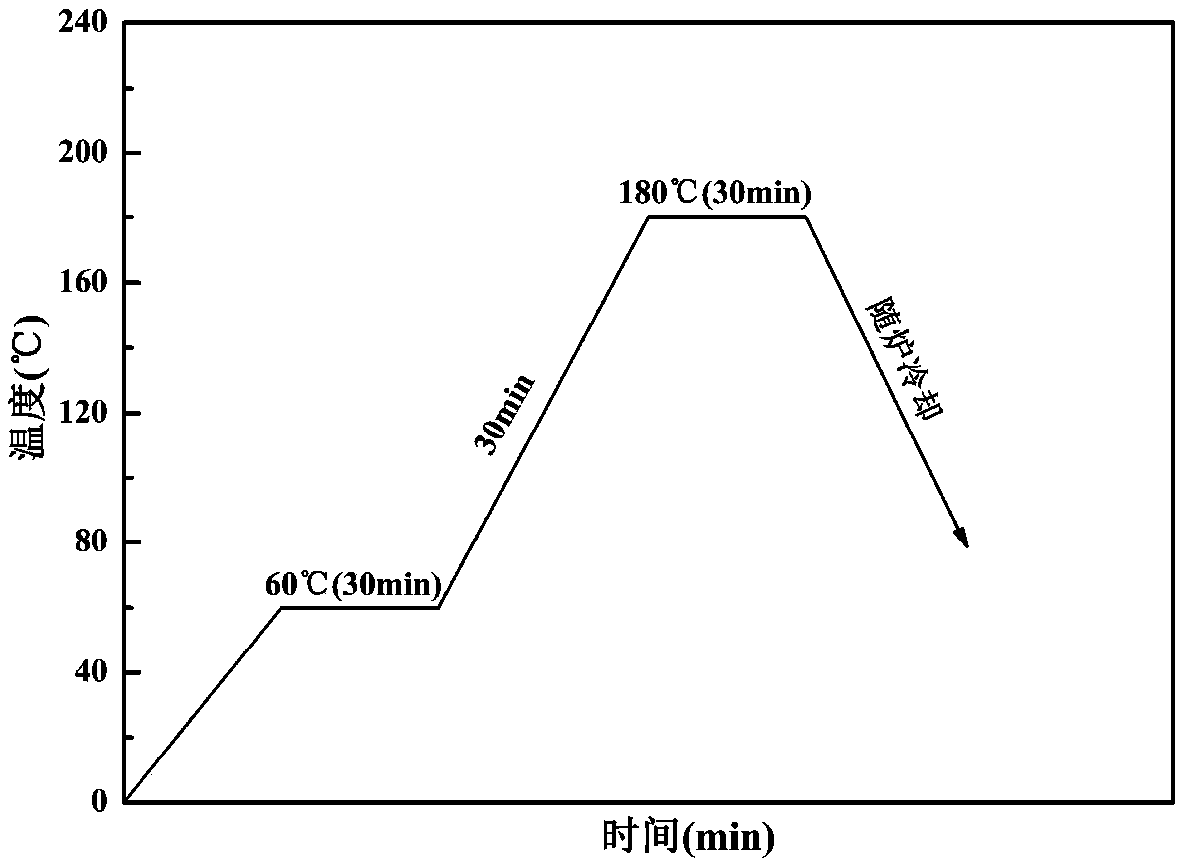

[0018] (2) The mixture of aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane was uniformly coated on Cr by dipping and pulling method. 3 C 2 -NiCr coating surface, stand and age at room temperature for 4 to 6 hours, and then cover Cr with aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane mixture 3 C 2 -NiCr coating was kept at 60°C for 0.5 hours, and then cured at 180°C for 0.5h to obtain Cr 3 C 2 -NiCr-aluminum silicon composite siloxane composite coating.

Embodiment 2

[0020] (1) First use supersonic flame spraying (HVOF or HVAF) to prepare Cr 3 C 2 -NiCr layer, mix aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane (MTMS) according to the mass ratio: 100:100 and stir for 4 to 6 hours to prepare aluminum-silicon composite sol (pH﹤1) and Methyltrimethoxysilane mixture.

[0021] (2) The mixture of aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane was uniformly coated on Cr by dipping and pulling method. 3 C 2 -NiCr coating surface, stand and age at room temperature for 4 to 6 hours, and then cover Cr with aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane mixture 3 C 2 -NiCr coating was kept at 60°C for 0.5 hours, and then cured at 180°C for 0.5h to obtain Cr 3 C 2 -NiCr-aluminum silicon composite siloxane composite coating.

Embodiment 3

[0023] (1) Firstly, the Cr3C2-NiCr layer is prepared by supersonic flame spraying (HVOF or HVAF), and the aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane (MTMS) are mixed and stirred according to the mass ratio: 100:150 After 4 to 6 hours, a mixture of aluminum-silicon composite sol (pH<1) and methyltrimethoxysilane is prepared.

[0024] (2) The mixture of aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane was uniformly coated on Cr by dipping and pulling method. 3 C 2 -NiCr coating surface, stand and age at room temperature for 4 to 6 hours, and then cover Cr with aluminum-silicon composite sol (pH﹤1) and methyltrimethoxysilane mixture 3 C 2 -NiCr coating was kept at 60°C for 0.5 hours, and then cured at 180°C for 0.5h to obtain Cr 3 C 2 -NiCr-aluminum silicon composite siloxane composite coating.

[0025] like figure 1 shown as Cr 3 C 2 - Curing curves of NiCr-aluminum-silicon composite siloxane composite coatings during preparation. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com