High-performance flame-retardant silane modified polyether sealant and preparation method thereof

A technology of silane-modified polyether and sealant, which is applied in the field of sealant, can solve the problems of poor compatibility of sealant matrix resin, reduce the mechanical properties of materials, destroy the atmospheric ozone layer, etc., achieve fast curing speed, reduce surface drying time, Ease of promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of polysiloxane comprises the steps:

[0034] (1) React γ-aminopropylmethyldiethoxysilane with deionized water (volume ratio 1:1) at 85°C for 4 hours to obtain aminosilane hydrolyzate, in which γ-aminopropylmethyldiethoxysilane The volume ratio of oxysilane to deionized water is 1:1;

[0035] (2) After dehydration of 12 parts by weight of aminosilane hydrolyzate obtained in step (1), with 94 parts by weight of octamethylcyclotetrasiloxane, 0.6 parts by weight of hexamethyldisiloxane and 0.1 parts by weight of potassium hydroxide React at 140°C for 5h to obtain polysiloxane.

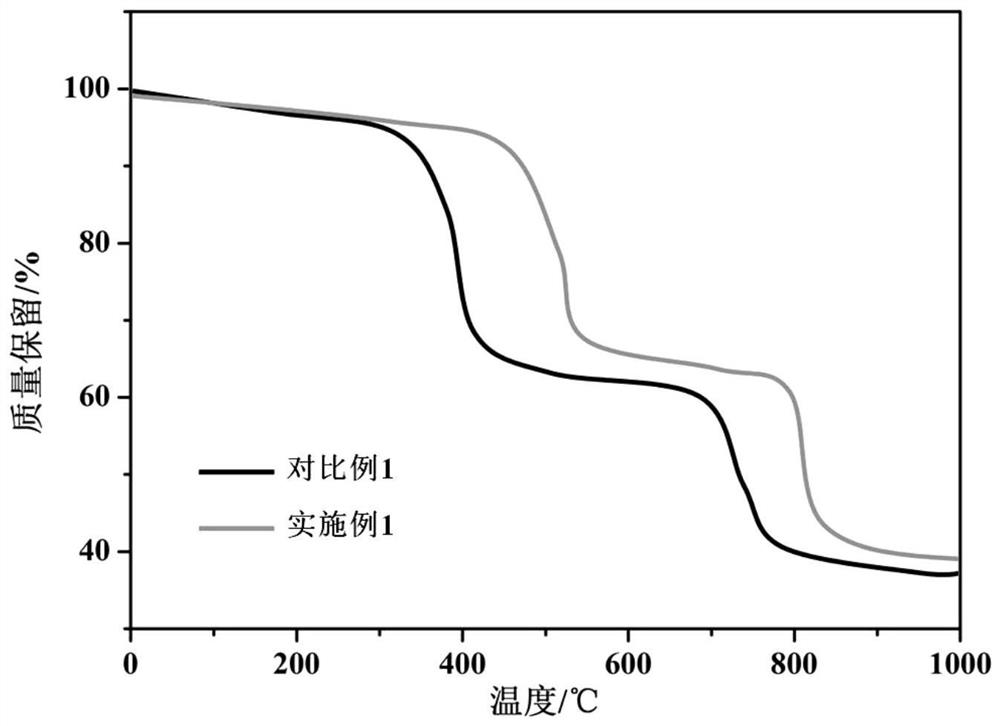

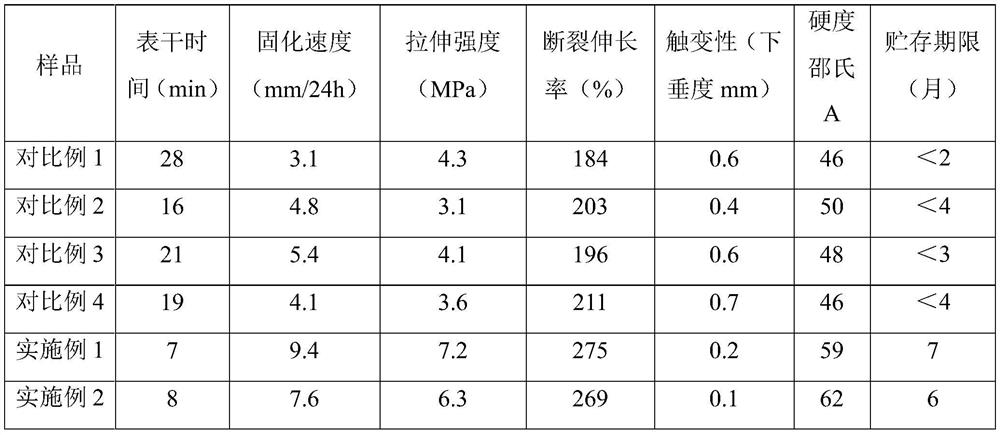

Embodiment 1

[0037] The preparation of pine lingxin acid anhydride:

[0038] Take pinesinic acid and put it into a four-neck flask equipped with stirring, thermometer and nitrogen protection, and turn on the oil bath. Start nitrogen protection and heat to 260°C, and keep the temperature for 30min; slowly add maleic anhydride (the molar ratio to pinicine acid is 2:1) several times, and react at 260°C for 6h after feeding; the crude product Cool in ice water, pulverize and wash with deionized water several times to obtain a crude product, then dry and dissolve in glacial acetic acid, heat and reflux for 2 hours, recrystallize twice, finally wash with deionized water several times, and dry That's it. The conversion rate (yield) obtained by measuring the acid value was 86.9%.

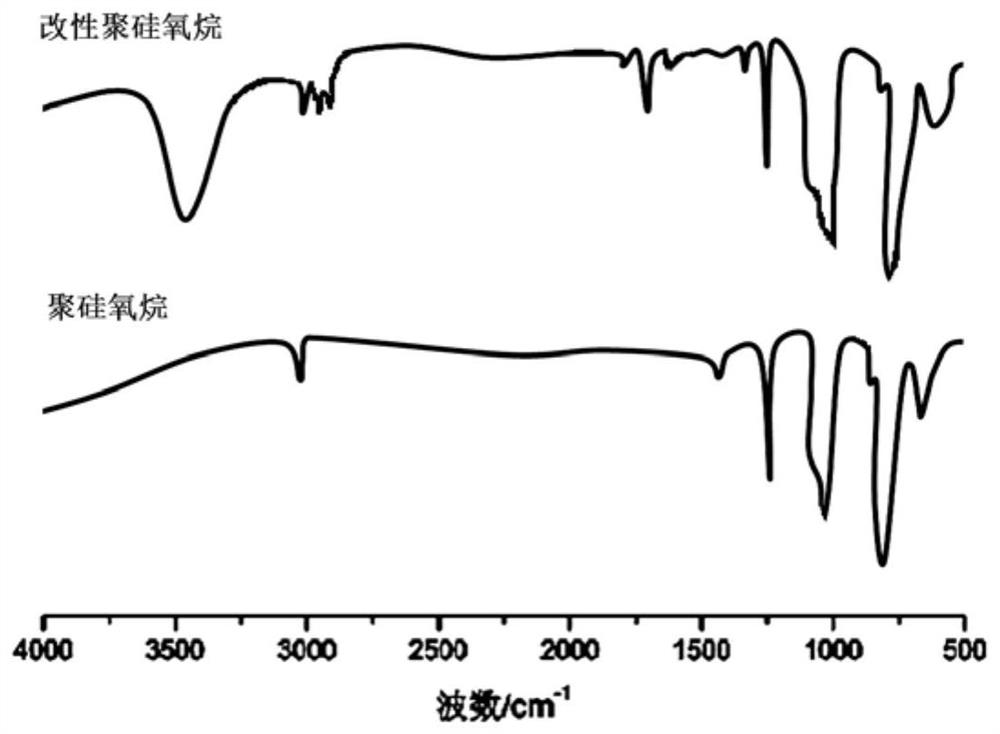

[0039]For the polysiloxane modified with maleic anhydride, 12 parts by weight of maleic anhydride and 46 parts by weight of polysiloxane were reacted at 95° C. for 4.5 hours to obtain the modified polysiloxane.

[00...

Embodiment 2

[0046] The preparation of pine lingxin acid anhydride and modified polysiloxane is the same as in Example 1.

[0047] A high-performance flame-retardant silane-modified polyether sealant. The raw material components include: by weight, 112 parts of modified polysiloxane-terminated polyether, 108 parts of active nano-calcium carbonate, 30 parts of polypropylene glycol, 22 parts of flame retardant filler, 4 parts of vinyltrimethoxysilane, 13 parts of white carbon black, 3 parts of bisaminosilane and 0.8 parts of organic chelated tin catalyst. The apparent viscosity of polyether is 13600mPa·s; the flame retardant filler is an intumescent flame retardant, and the mass ratio of acid source, carbon source and gas source is 2:0.9:1.2; the acid source is melamine polyphosphate, and the carbon source It is phenolic resin (PF), and the gas source is melamine (M EL).

[0048] The preparation of a high-performance flame-retardant silane-modified polyether sealant is the same as in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com