High-accuracy metal detection sensor device

A sensor device and metal detection technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to separate metal particles, poor anti-interference, and fluctuations in the sensitivity of metal foreign objects, and achieve excellent chemical corrosion resistance. Impact performance, effect of removing skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

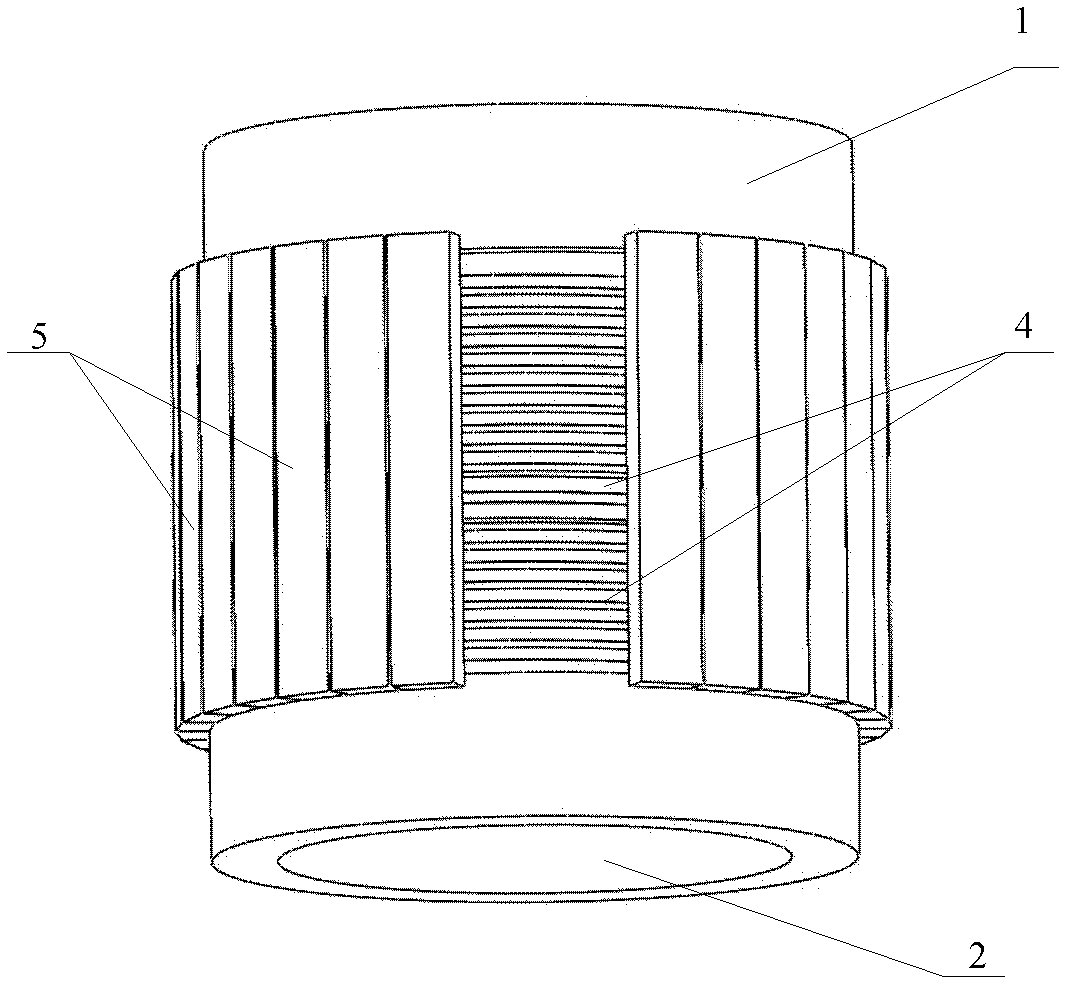

[0031] See Figure 1 to Figure 4 , The sensor device of the metal separator of the present invention includes: an inner cylinder 1 , a detection coil 4 , a magnetically conductive layer 5 and an electromagnetic shielding layer 6 .

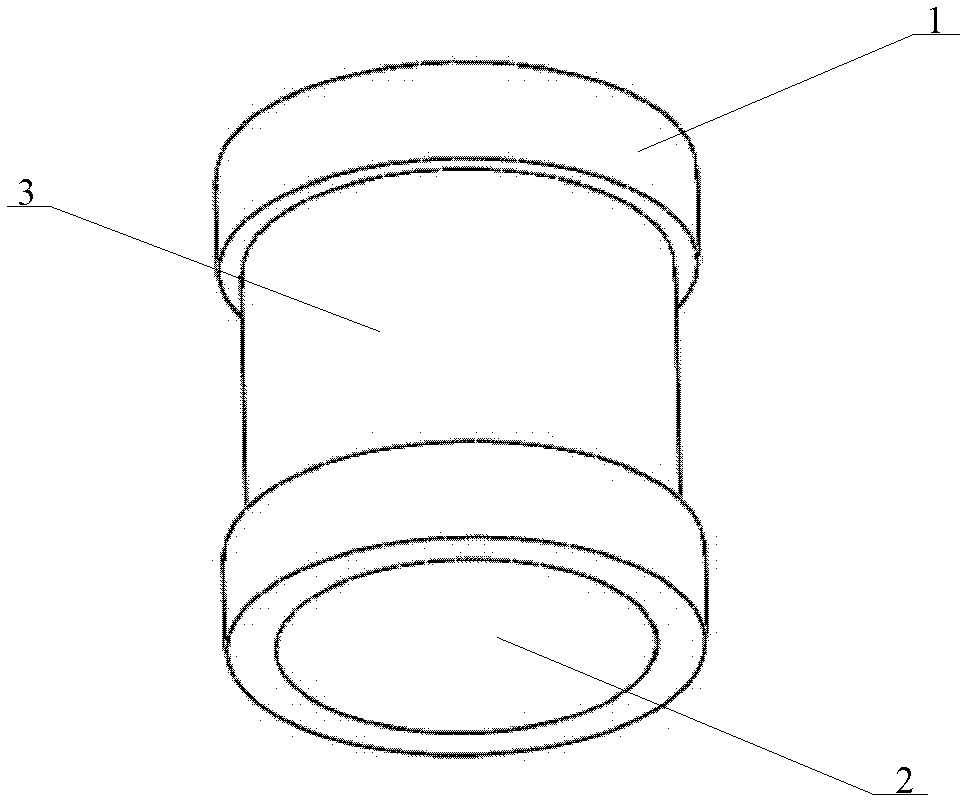

[0032] See figure 1 , the inner cylinder 1 communicates with the material transmission channel 2, and is made of random copolymerized polypropylene material. In order to facilitate and stabilize the detection coil, a groove 3 is provided in the middle of the outer surface of the inner cylinder.

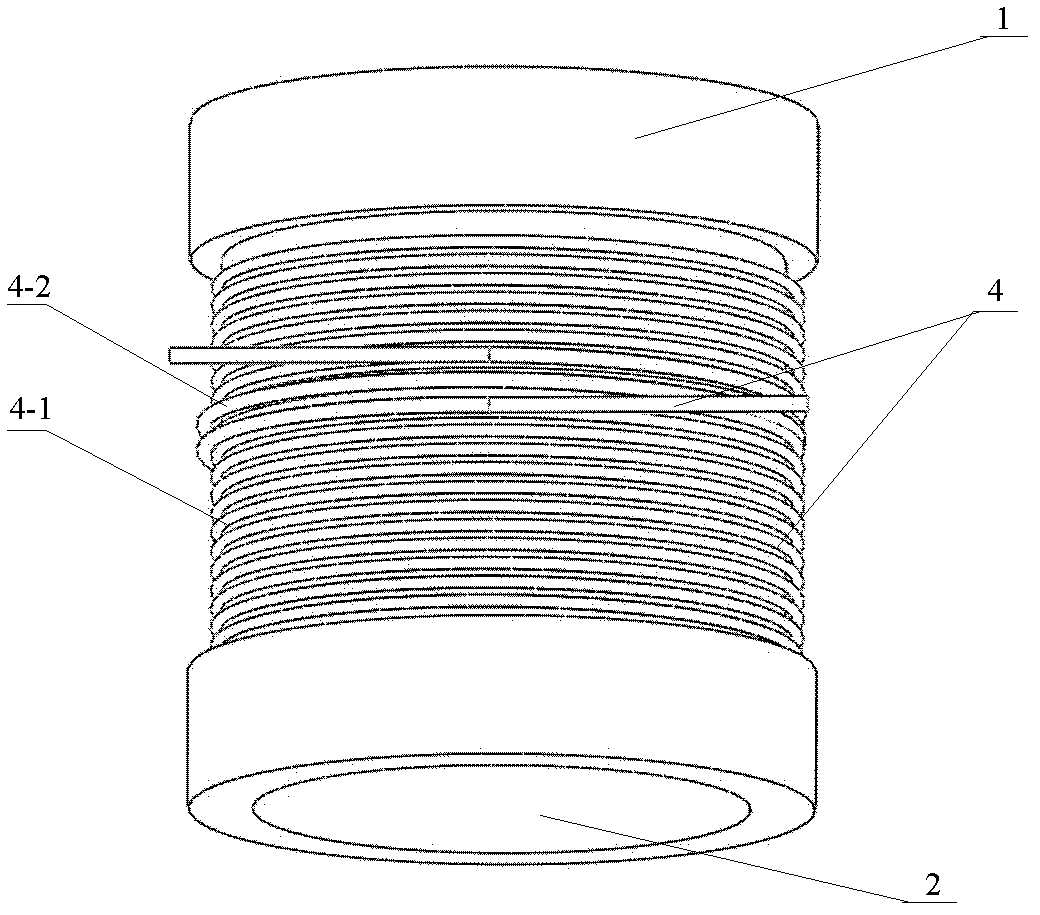

[0033] See figure 2 , the detection coil 4 is made of multi-strand high-frequency wire-wrapped wire, the main side coil 4-1 is wound in the groove 3 of the inner cylinder, and is formed in series with a non-polar high-frequency capacitor C after winding 15-30 LC oscillating circuit, the capacitor adopts a highly stable mica capacitor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com