Manufacturing method of photo-thermal power generation and heat collection and absorption temperature-resistant special alloy welding pipe

A technology of photothermal power generation and manufacturing method, which is applied in the field of welded pipe processing, can solve the problems of small bubbles in the crystallization line, unsatisfactory roughness, and easy mechanical damage, etc., and achieve excellent mechanical properties, good appearance and dimensional accuracy, and excellent corrosion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

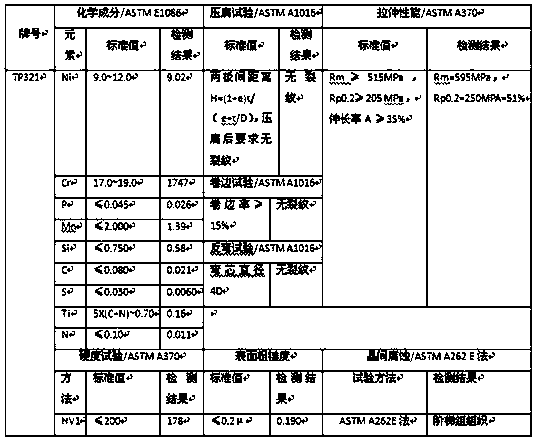

[0024] Steel type TP321, specification φ70*2.2mm, prepared by the following method:

[0025] 1) Coil forming: The roll arrangement and pass type in the existing forming technology are optimized, that is, the combination of seven flat and seven vertical rolls is used for online coil forming to ensure that the pipe is formed and the subsequent round straightening process There are no scratches and indentations on the surface, the quality of the forming seam is good, and a good forming effect can be obtained, laying a good foundation for the next welding process;

[0026] 2) Welding: Gas-shielded argon arc welding is used, and the welding torch shielding gas is 96% Ar 2 +4%H 2 , The shielding gas on the back of the weld is 100% Ar 2 , welding current 180-260A, welding voltage 9-15V, welding speed 300-800mm. This welding method can effectively control welding defects such as weld bubbles and inclusions, effectively improve the stability of the weld of austenitic stainless steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com