High strength sulfur resisting casing pipe and its heat treatment manufacturing method

A high-strength, quenched and tempered heat treatment technology, applied in heat treatment furnaces, heat treatment equipment, casings, etc., can solve the problems of materials and other issues, achieve the effects of reducing production costs, excellent hydrogen sulfide corrosion resistance, and reducing the amount of alloy used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

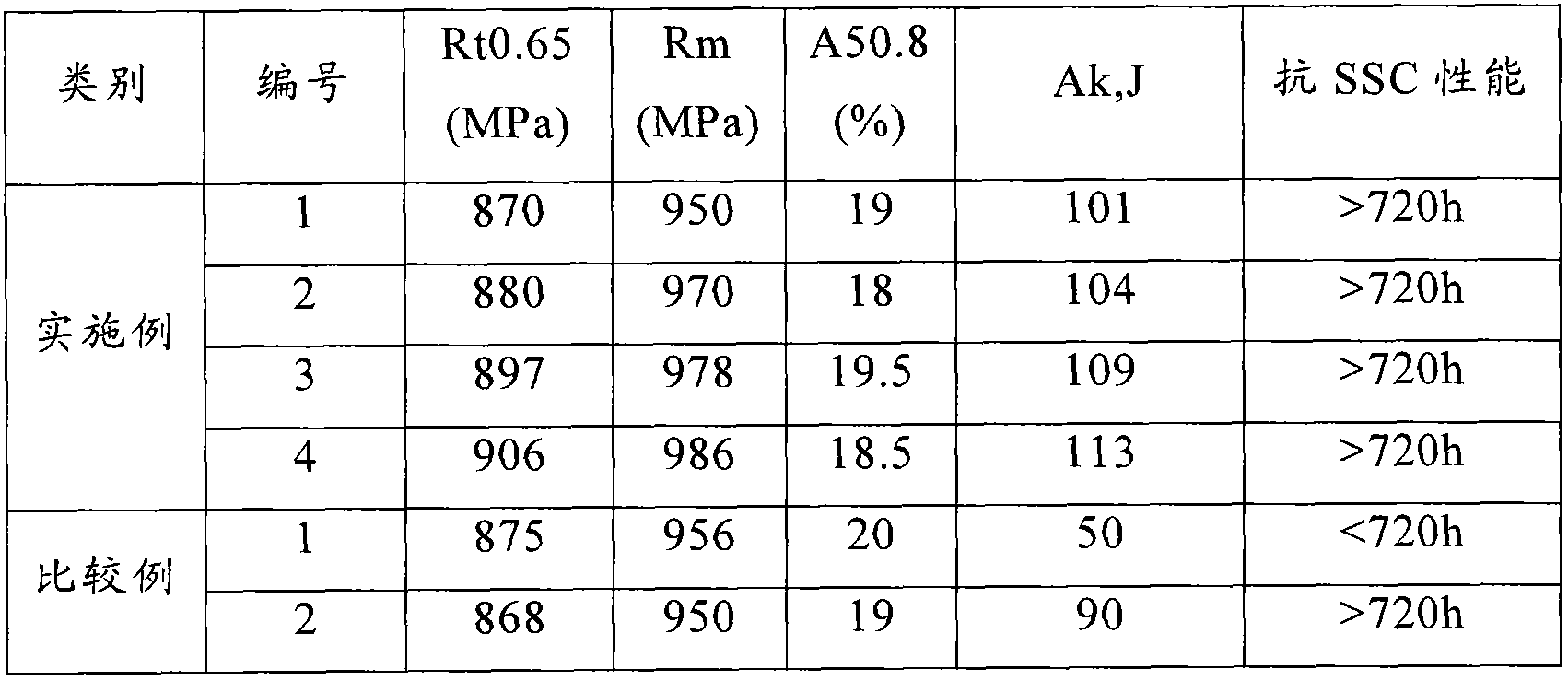

[0035] According to the chemical composition in Table 1, it is smelted, poured and rolled, and then the first quenching and tempering treatment is carried out. Among them, the heating temperature before quenching is 930 ° C, kept for 45 minutes, and quenched with water. The tempering temperature is 570°C, heat preservation for 90min, and air cooling after being out of the furnace. Then carry out the second quenching and tempering treatment, wherein, the heating temperature before quenching is 850°C, heat preservation for 45min, and water spray quenching. Tempering temperature is 650°C, heat preservation for 90 minutes, and air cooling after being out of the furnace.

[0036] Table 1, the chemical composition of the embodiment of the present invention and comparative example, wt%

[0037] C

Embodiment 2

[0039] Carry out smelting, pouring and rolling according to the chemical composition in Table 1, and then perform the first quenching and tempering treatment, in which, the heating temperature before quenching is 1000°C, heat preservation for 120min, and water spray quenching. The tempering temperature is 650°C, heat preservation for 150min, and air cooling after being out of the furnace. Then carry out the second quenching and tempering treatment, wherein, the heating temperature before quenching is 950°C, keep warm for 120min, and quench with water. The tempering temperature is 710°C, heat preservation for 150min, and air cooling after being out of the furnace.

Embodiment 3

[0041] Carry out smelting, pouring and rolling according to the chemical composition in Table 1, and then perform the first quenching and tempering treatment, in which the heating temperature before quenching is 930°C, hold for 45min, and quench with water. The tempering temperature is 570°C, heat preservation for 90min, and air cooling after being out of the furnace. Then carry out the second quenching and tempering treatment, wherein, the heating temperature before quenching is 950°C, keep warm for 120min, and quench with water. The tempering temperature is 710°C, heat preservation for 150min, and air cooling after being out of the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com