Low magnetism steel resisting sea water corrosion

A low-magnetic steel and seawater-resistant technology, which is applied in the field of alloy steel manufacturing, can solve problems such as poor processing performance, welding process and corrosion resistance, failure to meet the requirements of corrosion-resistant low-magnetic steel, and low magnetic properties that cannot meet the requirements of use. , to achieve the effects of good crevice corrosion performance, low smelting cost, and the probability of inhibiting intergranular corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

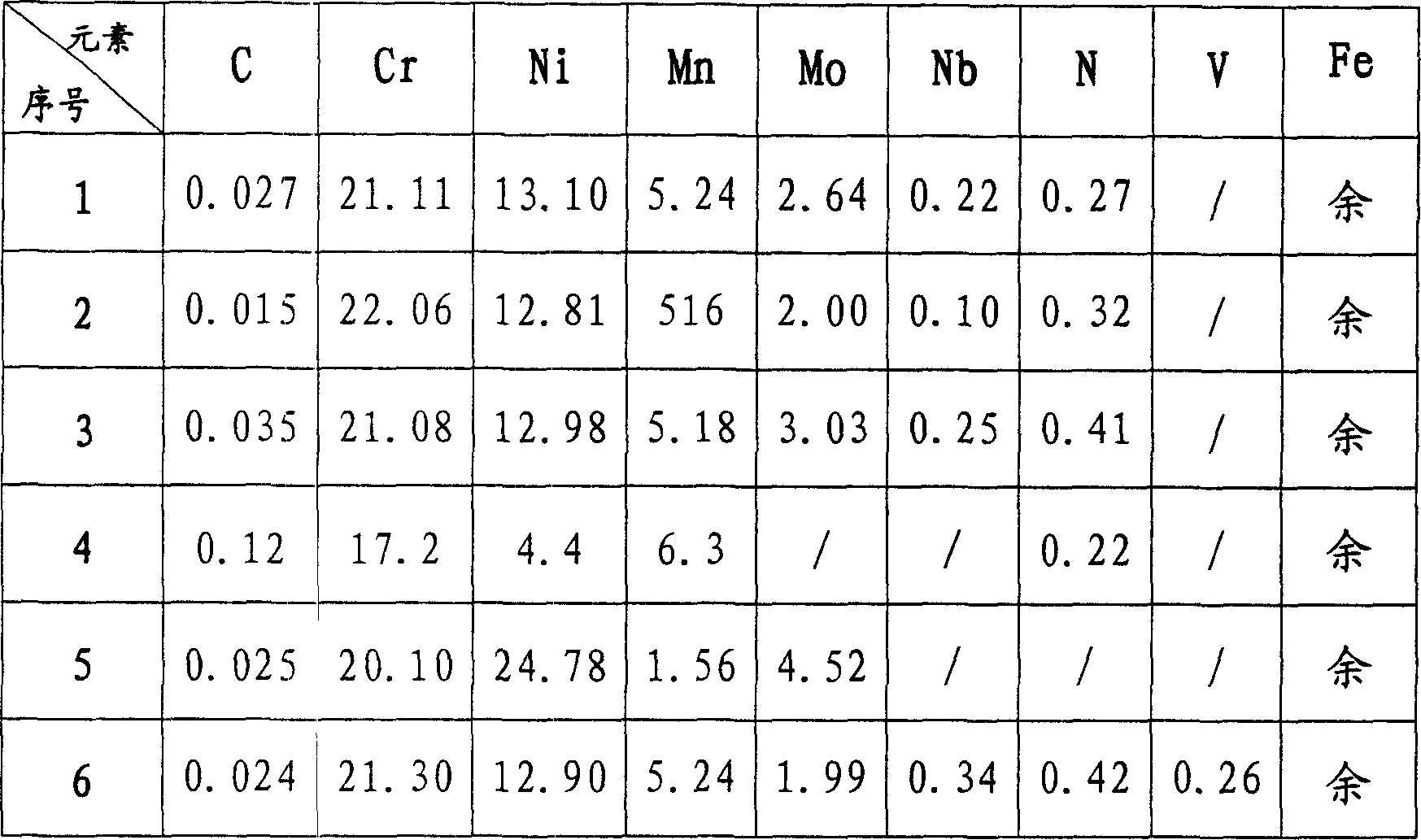

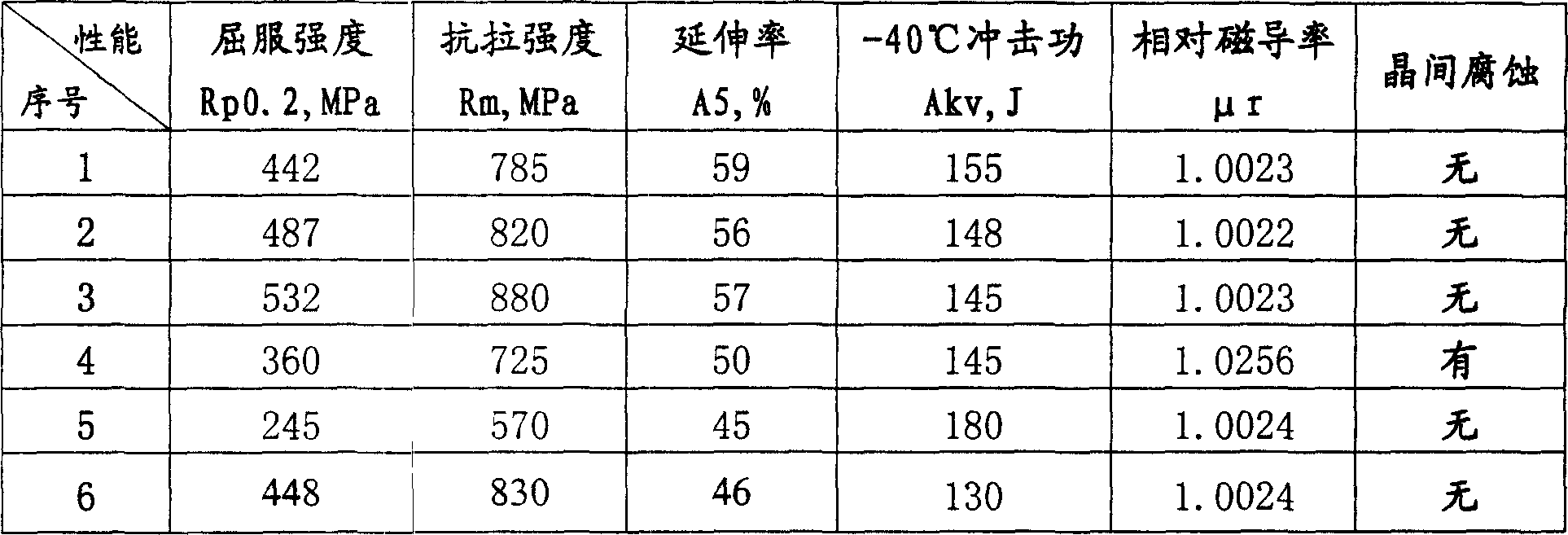

[0012] In the embodiment of the present invention, three sets of comparative tests were carried out within the composition range of the seawater corrosion-resistant low-magnetic steel designed by us. For the convenience of comparison, we also listed three groups of typical steels in the prior art (see Table 1 for comparison results). The preparation of the materials used in the comparison experiments of the examples are all using ferrochrome, ferromolybdenum, industrial electrolytic manganese, ferroniobium, metallic nickel and waste chromium-nickel stainless steel as raw materials, and the smelting process of electric furnace + AOD refining +1050-1150°C Solution treatment, and then sampling and processing into test samples of standard specifications (see Table 2 for comparison results). In the comparison table of the embodiments of the present invention, the serial numbers 1-3 are the seawater corrosion-resistant low-magnetic steels of the present invention; the serial numbers 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com