WDZB-BYN low-smoke halogen-free nylon power line and preparation method thereof

A technology of WDZB-BYN and power cords, which is applied in the direction of cable/conductor manufacturing, circuits, insulated cables, etc., and can solve power cord wear resistance, corrosion resistance, aging resistance, low weather resistance, thermal stability and heat resistance Low shrinkage effect, short service life of the power cord, etc., to achieve good environmental protection, reduce potential short-circuit accidents, and excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

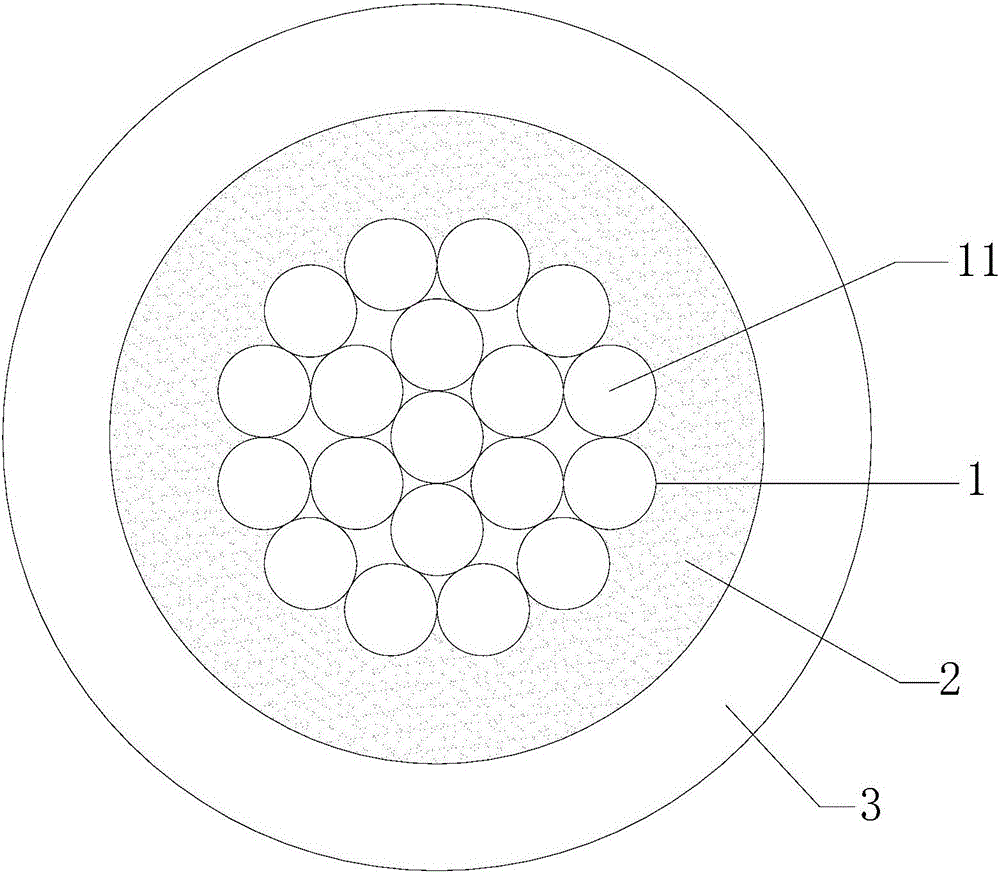

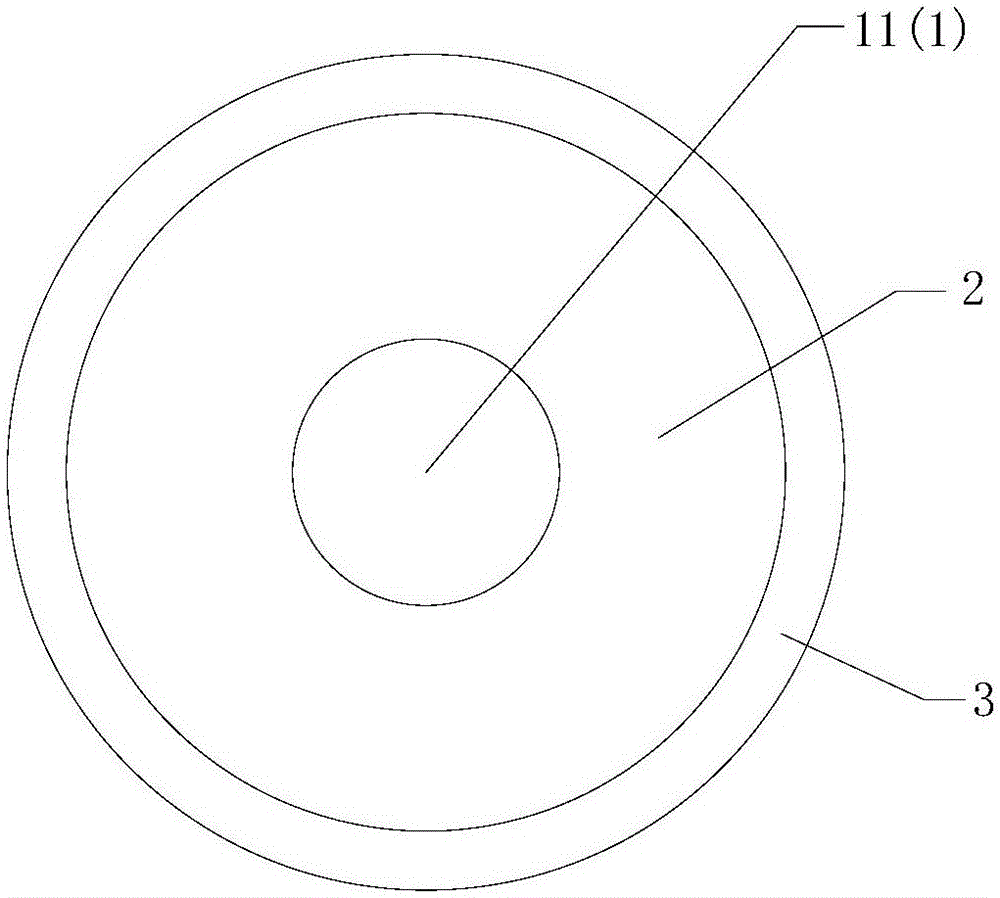

[0030] The conductor 1 of a WDZB-BYN low-smoke halogen-free nylon power cord provided in this embodiment 1 is formed by twisting a single or several conductor wires 11, and its preparation method includes the following steps:

[0031] Step 1. Preparing conductors: drawing and annealing copper monofilaments to obtain thin conductor wires 11 , and tightly twisting a single or several conductor wires 11 into a conductor 1 by bundle twisting.

[0032] Step 2. Double-layer co-extrusion: Two extruders are used to feed low-smoke halogen-free polyolefin insulation material and nylon sheath material into their respective extruders, and then extrude and coat the conductor 1 at the same time after melting. Also, get the power cord.

[0033] Wherein, the two extruders adopt the same non-adjustable eccentric head, and the two extruders adopt the extruder of the double-layer co-extrusion mold.

[0034] Furthermore, the heating of the non-adjustable eccentric head is two-stage, one section ...

Embodiment 2

[0039] The conductor 1 of a WDZB-BYN low-smoke halogen-free nylon power cord of the second embodiment is formed by twisting a single or several conductor wires 11, and its preparation method includes the following steps:

[0040] Step 1. Preparing conductors: drawing and annealing copper monofilaments to obtain thin conductor wires 11 , and twisting a single or several conductor wires 11 into a conductor 1 by bundle twisting.

[0041] Step 2, secondary extrusion molding:

[0042] a) Firstly, on an extruder, the low-smoke halogen-free polyolefin insulating material is fed into the extruder, melted and extruded on the outer layer of the conductor 1 to obtain the insulating layer 2 .

[0043] b) Then, in another extruder, the nylon sheath material is fed into the extruder, and after being melted, it is extruded on the outer layer of the insulating layer 2 with printed characters to obtain the sheath 3 .

[0044] Wherein, before the end of step a) and the beginning of step b), af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com