Conductive nano fluorocarbon coating

A technology of fluorocarbon coatings and conductive nanometers, applied in conductive coatings, anti-corrosion coatings, coatings, etc., can solve the problems of weak conductivity, degradation and cracking, poor high temperature resistance of conductive coatings, etc., and achieve excellent soil resistance, Improved thermal stability and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

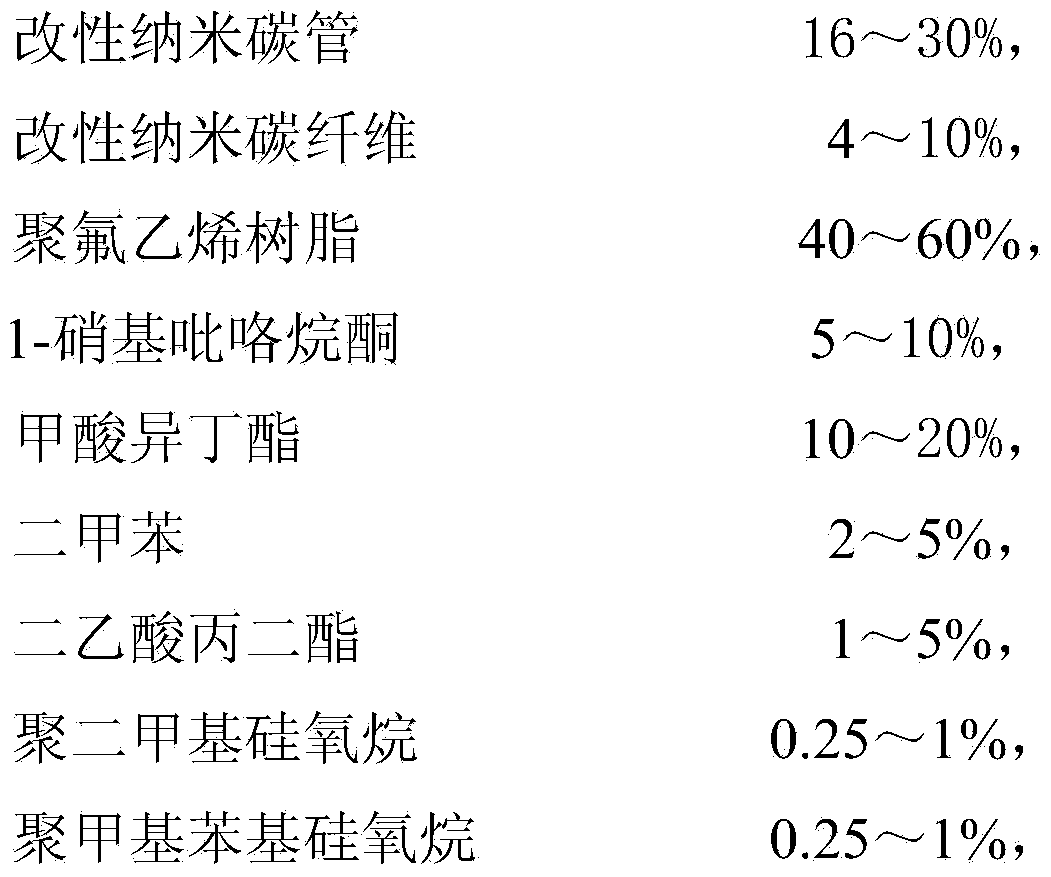

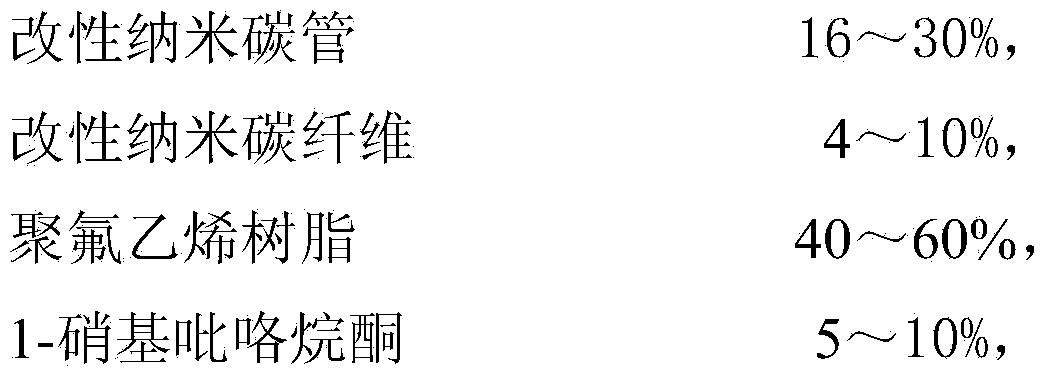

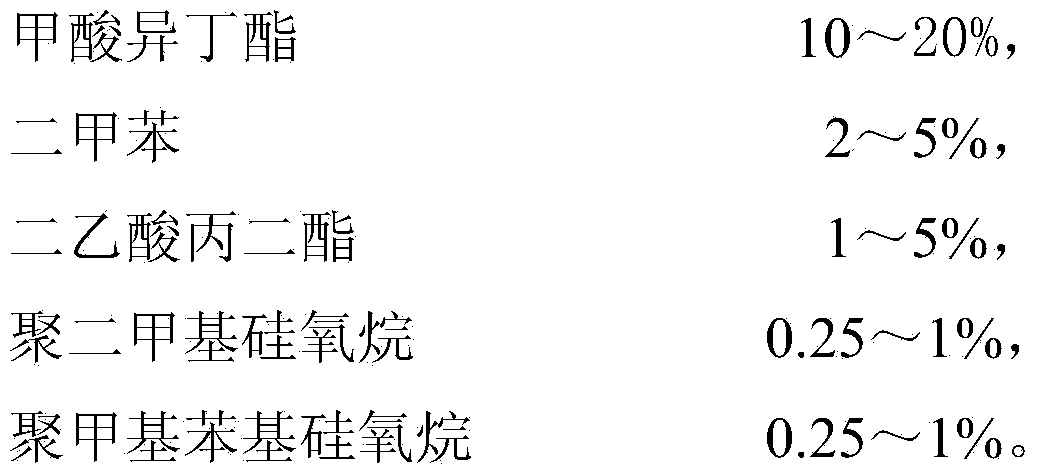

Method used

Image

Examples

Embodiment 1

[0022] Example 1: First, the modified carbon nanotubes with a diameter of Ф5nm and a length of 0.1 μm were prepared using the following raw materials and steps:

[0023] (1) Take 16 kg of carbon nanotubes, put them into a propanol solution, prepare a propanol solution with a mass concentration of 2%, oscillate ultrasonically for 20 minutes, and mix evenly to obtain a carbon nanotube mixture;

[0024] (2), according to the weight ratio of 1% of the carbon nanotube mixture obtained in step (1), take the silane coupling agent and put it into deionized water, configure it into an aqueous solution with a mass concentration of 2%, and use oxalic acid to adjust the pH value to 8, Ultrasonic oscillation for 10 minutes to pre-hydrolyze the injected silane coupling agent in deionized water to obtain a hydrolyzed solution of the silane coupling agent;

[0025] (3) Add the silane coupling agent hydrolyzate obtained in step (2) into the carbon nanotube mixture obtained in step (1), stir ev...

Embodiment 2

[0031] Embodiment 2: First, the modified carbon nanotubes with a tube diameter of Ф100 nm and a tube length of 50 μm were produced using the following raw materials and steps:

[0032] (1) Take 30 kg of carbon nanotubes and put them into a butanol solution, prepare a butanol solution with a mass concentration of 8%, oscillate ultrasonically for 40 minutes, and mix evenly to obtain a carbon nanotube mixture;

[0033] (2), according to the weight ratio of 3% of the carbon nanotube mixture obtained in step (1), take the silane coupling agent and put it into deionized water, configure it into an aqueous solution with a mass concentration of 6%, and use oxalic acid to adjust the pH value to 10, Ultrasonic vibration for 30 minutes to pre-hydrolyze the injected silane coupling agent in deionized water to obtain a silane coupling agent hydrolyzate;

[0034] (3) Add the silane coupling agent hydrolyzate obtained in step (2) into the carbon nanotube mixture obtained in step (1), stir ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com