400 Mpa-grade construction steel with excellent corrosion resistance and production method

A technology for building steel and corrosion performance, applied in the field of corrosion-resistant steel and its production technology control, can solve the problems of poor low-temperature impact performance and weldability, high phosphorus content, etc., and achieve the effect of excellent corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

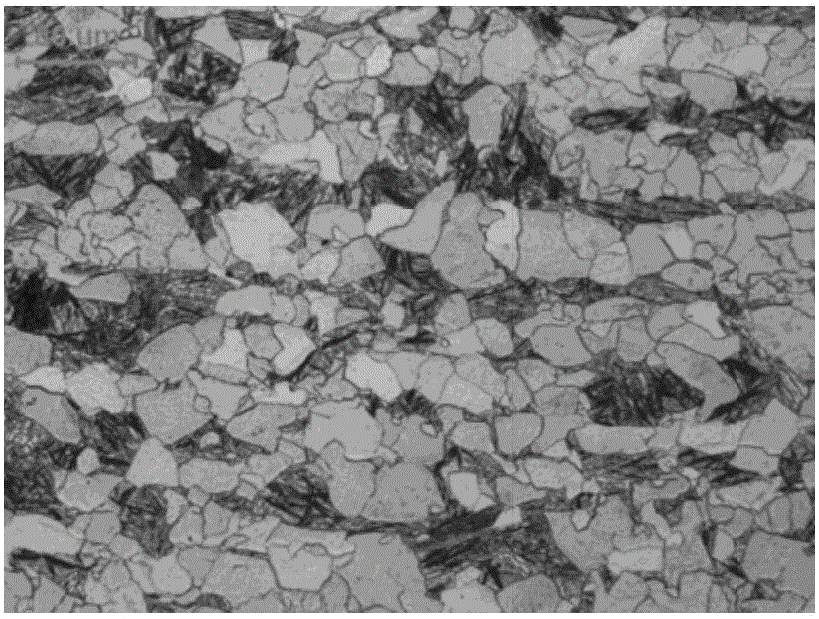

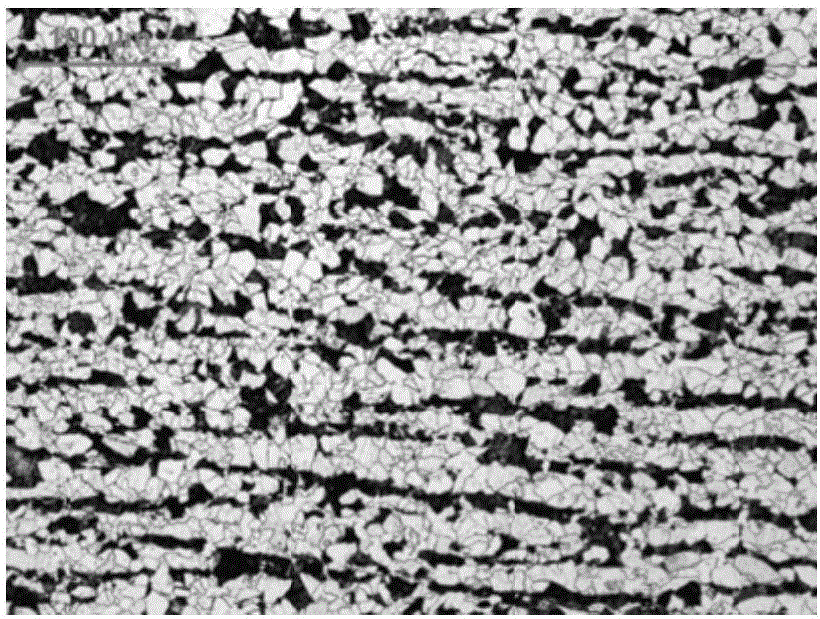

Image

Examples

Embodiment 1

[0028] The chemical composition and mass percentage of a 400Mpa grade construction steel with excellent corrosion performance are:

[0029] Composition 1 The steel composition C: 0.14%, Si: 0.4%, Mn: 1.4%, P: 0.015, S: 0.01, Cr: 0.8%, Cu: 0.6%, Ni: 0.6%, N: 0.01%, Mo : 0.15%, the balance is Fe.

[0030] Composition 2 The steel composition C: 0.05%, Si: 0.5%, Mn: 1.5%, P: 0.015, S: 0.01, Cr: 1.45%, Cu: 1.0%, Ni: 1.0%, N: 0.02%, Mo : 0.4%, the balance is Fe.

[0031] Composition 3 The steel composition C: 0.10%, Si: 0.4%, Mn: 1.3%, P: 0.015, S: 0.01, Cr: 1.0%, Cu: 0.5%, Ni: 1.0%, N: 0.01%, Mo : 0.4%, the balance is Fe.

[0032] The production process is as follows: firstly carry out desulfurization pretreatment of molten iron, smelting in converter with top-bottom rich blowing, refining in LF furnace, continuous casting with full protection, and the billet size is 150*150mm;

[0033] Control the end point of the converter to 0.03%, control the tapping temperature at 1695°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com