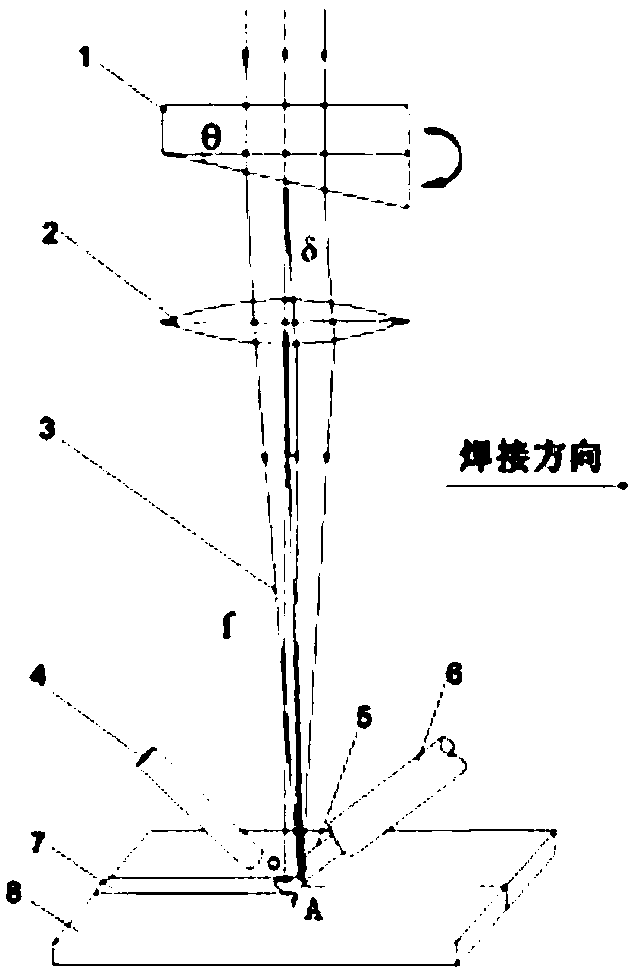

Aluminum alloy laser focus rotation wire-filling welding method

A welding method and focus technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of low mechanical properties of joints, improve weld morphology, refine weld grains, and inhibit porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

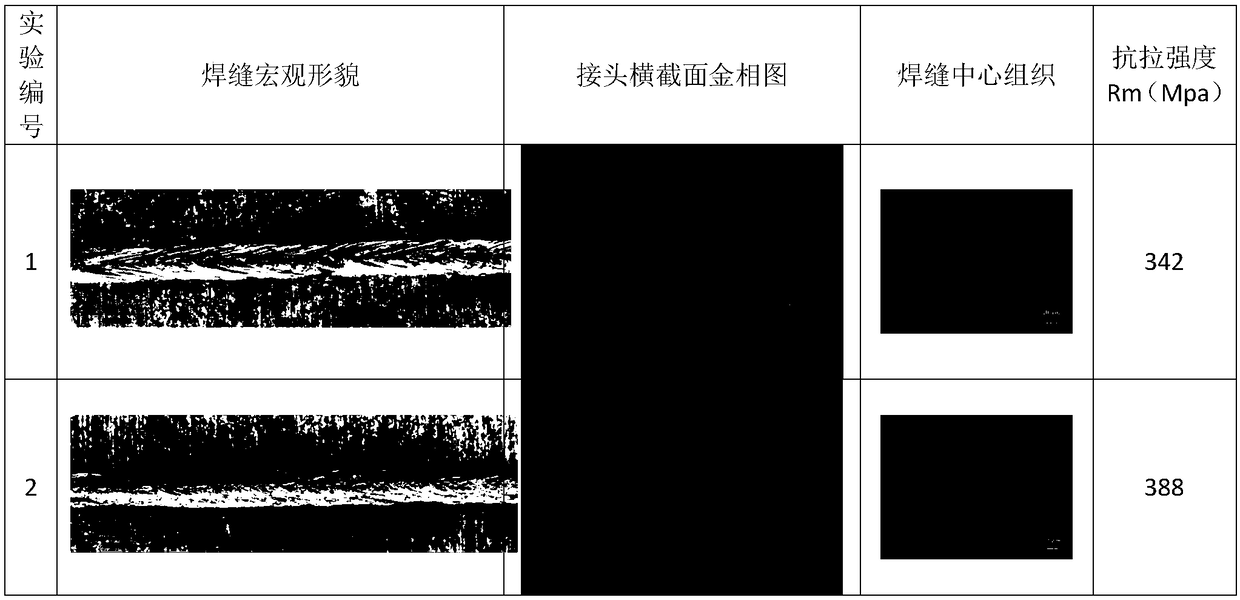

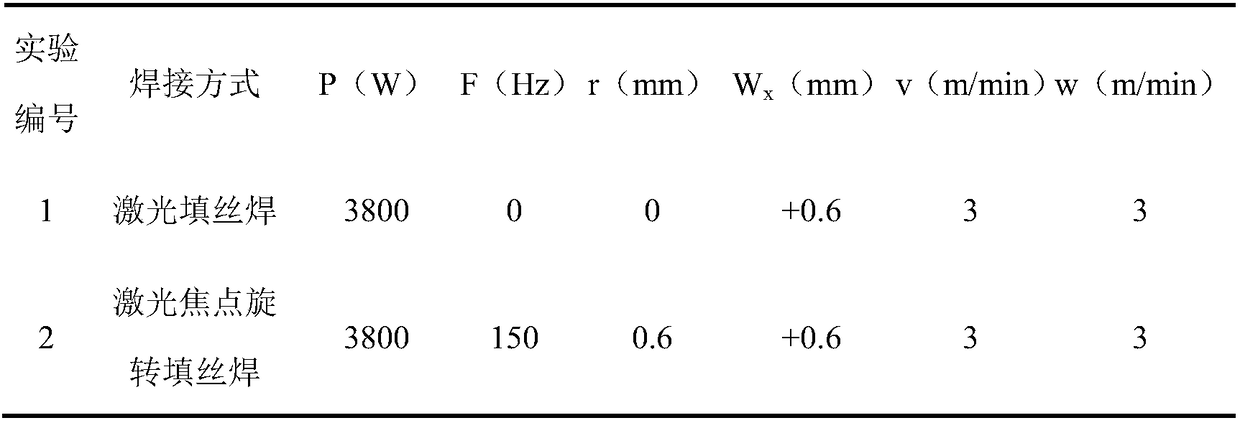

[0014] The welding process parameters of Embodiment 1 are shown in the following table, wherein, P is the laser power, F is the focus rotation frequency, r is the focus rotation radius, and W x is the light wire spacing, v is the welding speed, and w is the wire filling speed.

[0015]

[0016] The material used in Example 1 is 2060 aluminum-lithium alloy, the sample size is 100mm × 60mm × 2mm, the surface oxide film is removed with NaOH solution before welding, and 30% HNO 3 Solution neutralizes residual lye. Use 1.2mm 4047Al-Si welding wire. Argon gas shielding (output from sideshaft nozzle 4) is adopted, and the shielding gas flow rate is 25L / min. The weld type is a butt weld.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com