Quenching type pulsation welding method

A welding method and cold technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of "impurity" in the weld, the decline of mechanical properties and corrosion properties, and agglomeration, so as to improve the mechanical properties and corrosion resistance Performance, reduction of grain growth time, effect of weld grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Two Inconel601 nickel-based alloy weldments of 200mm×100mm×3mm are assembled, with a gap of 1mm, and 3 points at an interval of 100mm;

[0020] 2. Suspend the weldment horizontally and clamp it in the welding tool;

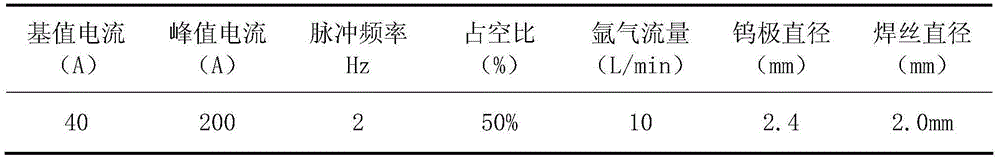

[0021] 3. Pulse tungsten argon arc manual welding is adopted, and the arc welding power supply is adjusted according to the welding process parameters shown in Table 1;

[0022] Table 1

[0023]

[0024] 4. A welder uses manual welding method to strike the arc on the front of the weldment to start welding;

[0025] 5. After A welder fills the ERNiCr-3 nickel-based alloy welding wire for about 3 seconds, he stops filling the welding wire and at the same time quickly advances the welding torch about 10mm to the unwelded place, and keeps the arc from extinguishing;

[0026] 6. While welder A removes the welding torch, welder B sprays liquid nitrogen quickly on the front of the weldment, at the center of the welding pool for about 1 second, so that the ...

Embodiment 2

[0037] 1. Two Inconel601 nickel-based alloy weldments of 200mm×100mm×3mm are assembled, with a gap of 1mm, and 3 points at an interval of 100mm;

[0038] 2. Suspend the weldment horizontally and clamp it in the welding tool;

[0039] 3. Pulse tungsten argon arc manual welding is adopted, and the arc welding power supply is adjusted according to the welding process parameters shown in Table 3;

[0040] table 3

[0041]

[0042] 4. A welder uses manual welding method to strike the arc on the front of the weldment to start welding;

[0043] 5. After A welder fills ERNiCr-3 nickel-based alloy welding wire for about 3 seconds, he stops filling the welding wire and at the same time quickly advances the welding torch about 10mm to the unwelded place, and keeps the arc from extinguishing;

[0044] 6. While welder A removes the welding torch, welder B sprays liquid nitrogen quickly on the back of the weldment, at the center of the welding pool for about 1 second, so that the molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com