Multi-physical-field auxiliary dissimilar metal material welding method

A technology of dissimilar metals and multi-physics fields, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve problems affecting interface bonding, grain coarsening, uneven weld composition, etc., to achieve reduction The use of materials, the refinement of weld grains, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A multi-physics field-assisted welding method for dissimilar metal materials, the steps are as follows:

[0035] 1) Remove grease and stains from the surface of the pure aluminum plate and pure iron plate, and clean it with pickling method to remove the oxide film initially, and preheat it in the atmospheric environment after drying, and the preheating temperature is 300°C;

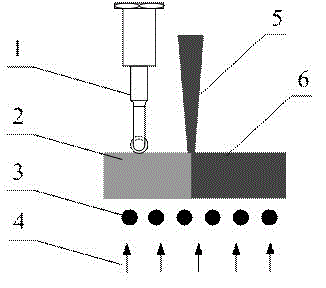

[0036] 2) Under the conditions of atmospheric environment, nitrogen or argon atmosphere, arc heating is used to melt the junction of pure aluminum plates and pure iron plates placed side by side into liquid metal, and at the same time apply ultrasonic and magnetic dual physical fields, such as figure 1 shown, where the ultrasonic frequency is 2×10 4 Hz, the output amplitude of the tool head is 10μm, the output power of the ultrasonic power supply is 2kW, the working pressure is 3.0Mpa, the magnetic field strength is 3T, the frequency of the alternating magnetic field is 10Hz, and the composite weld...

Embodiment 2

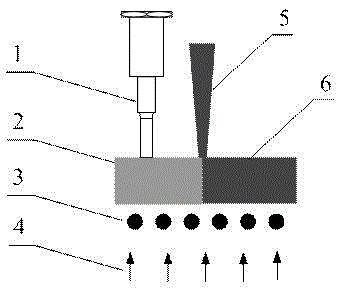

[0039] A multi-physics field-assisted welding method for dissimilar metal materials, the steps are basically the same as in Example 1, the difference is that the shape of the ultrasonic application device used is a roller type, such as figure 2 shown.

Embodiment 3

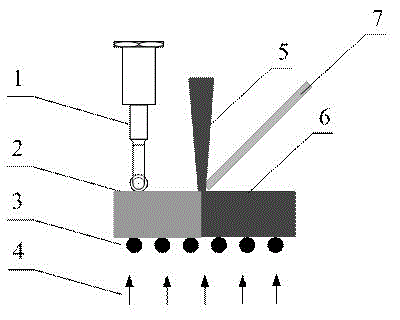

[0041] A multi-physics field-assisted welding method for dissimilar metal materials, the steps are basically the same as in Example 1, the difference is that a filler material is used between the pure aluminum plate and the pure iron plate, the composition is Zn-Al alloy, and the filler material is placed in advance Between two metals, the thickness is 0.5mm, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com