Trapezoidal wave modulation welding current waveform

A welding current and trapezoidal wave technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of loss, reduce welding stability, etc., achieve the effect of refining weld grains and reducing the incidence of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

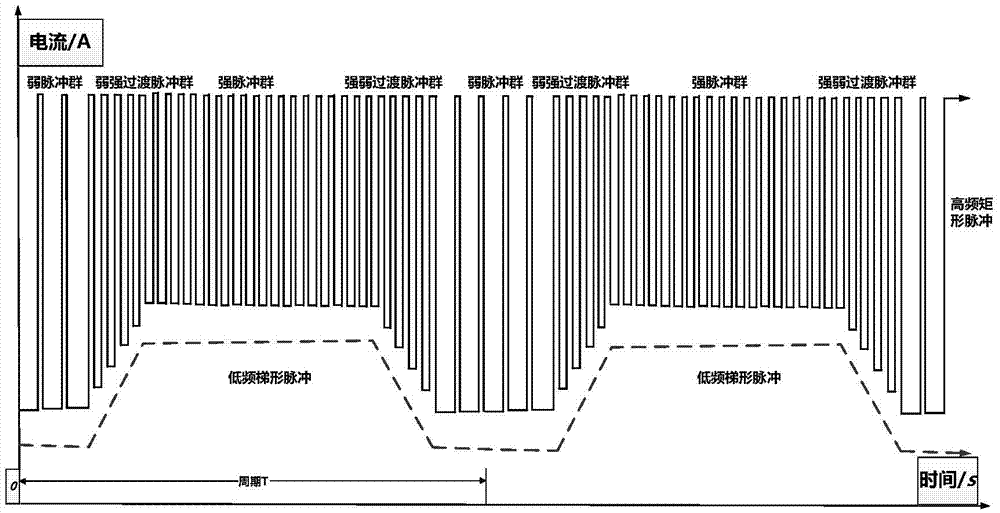

[0027] Such as figure 1 Shown is a structural schematic diagram of the trapezoidal wave modulation welding current waveform proposed by the present invention.

[0028] This waveform has the following characteristics:

[0029] 1. The waveform consists of coupled low-frequency trapezoidal pulses and high-frequency rectangular pulses.

[0030] 2. The waveform consists of strong bursts, strong-weak transition bursts, weak bursts and weak-strong transition bursts.

[0031] 3. The number of pulses in the strong-weak transition pulse group and the weak-strong transition pulse group is the same in the waveform.

[0032] 4. The peak current value of all high-frequency rectangular pulses in this waveform is the same.

[0033] 5. The peak current duration of all high-frequency rectangular pulses in this waveform is the same.

[0034] 6. The base value current of the weak pulse group in this waveform is smaller than the base value current of the strong pulse group.

[0035] 7. The nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com