Deformation heat treatment method for modifying welding seam tissue capability

A deformation heat treatment, microstructure and property technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as reducing the quality of welds, and achieve the effects of eliminating residual stress, improving plastic toughness, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

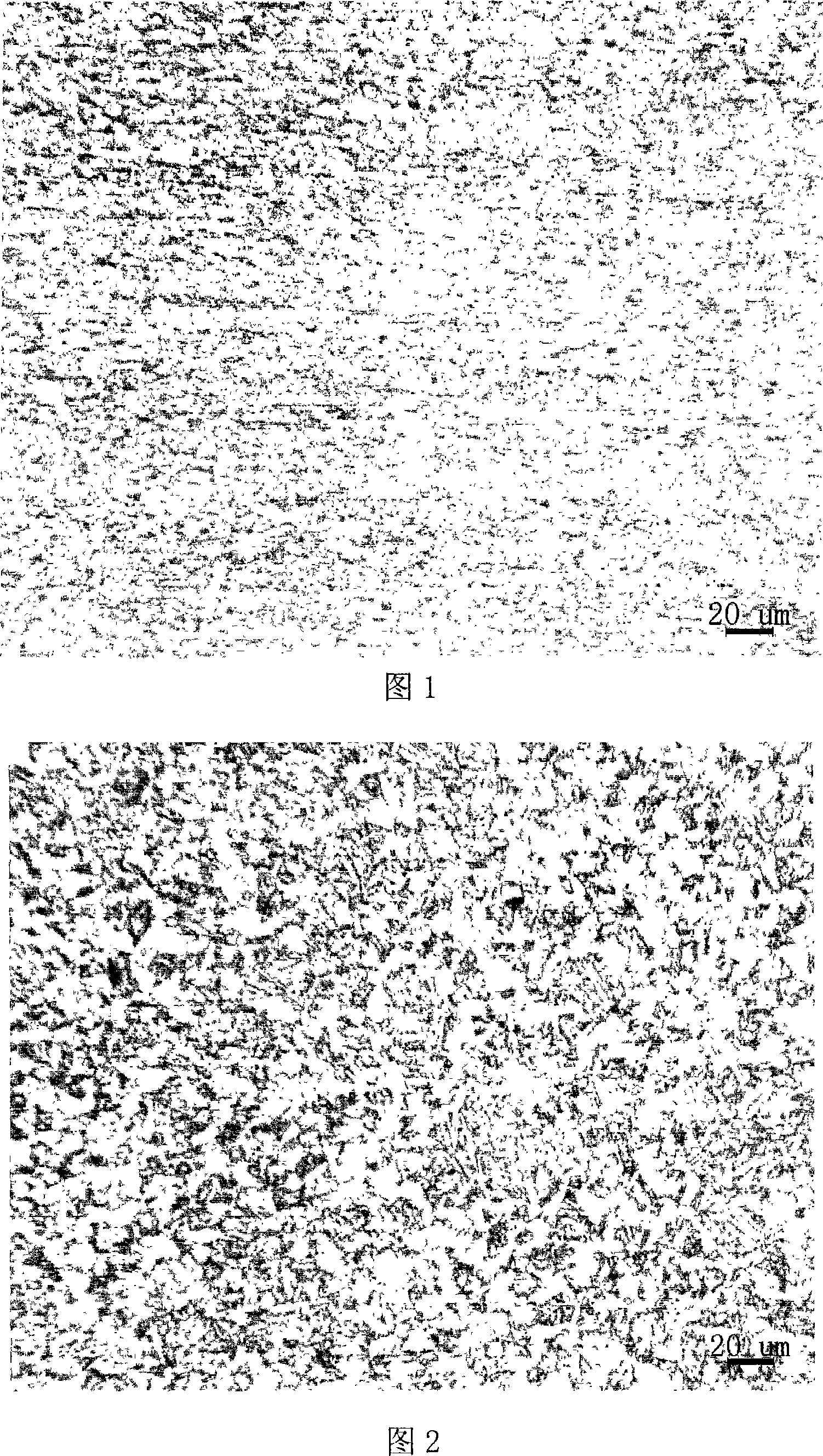

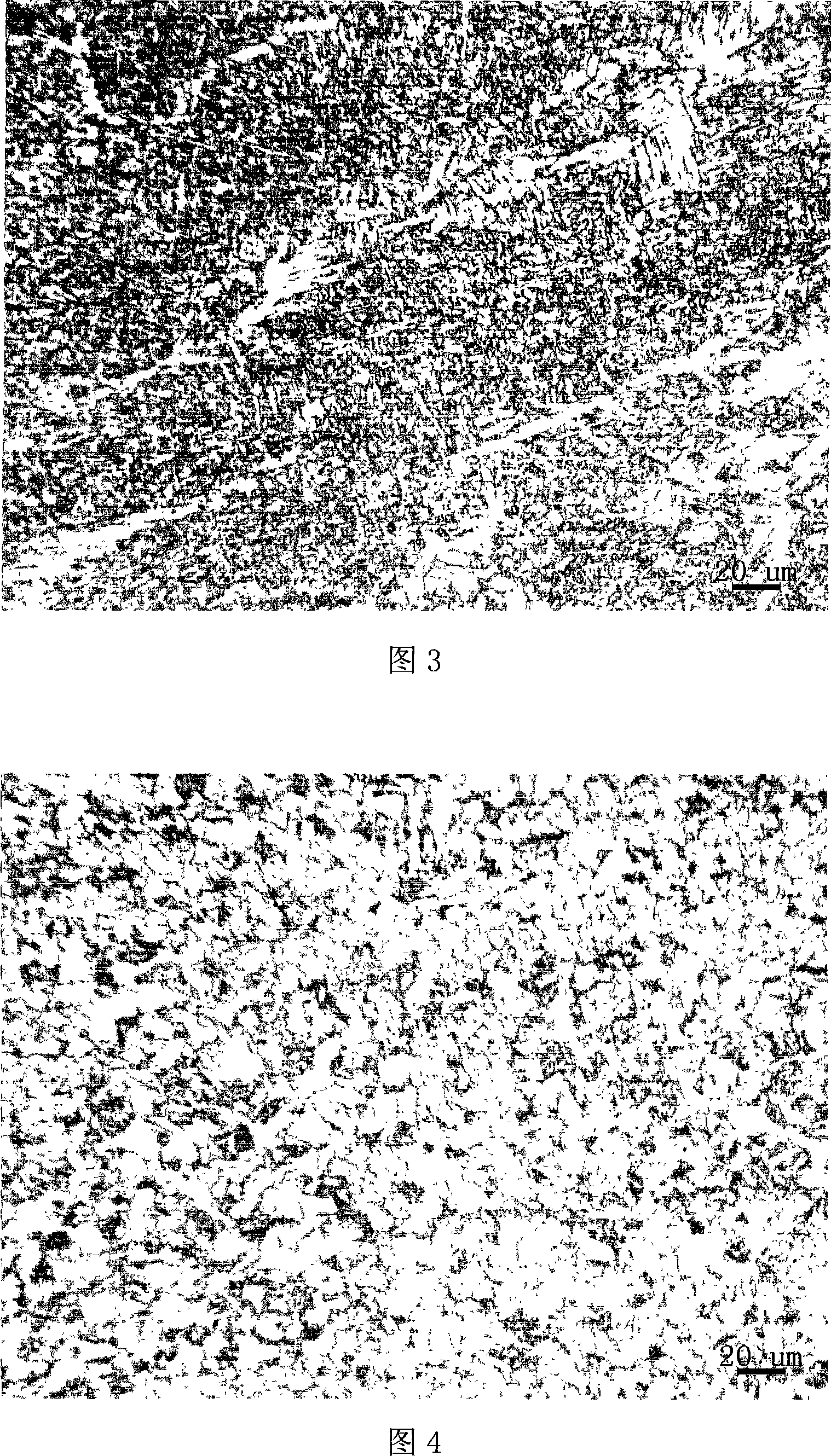

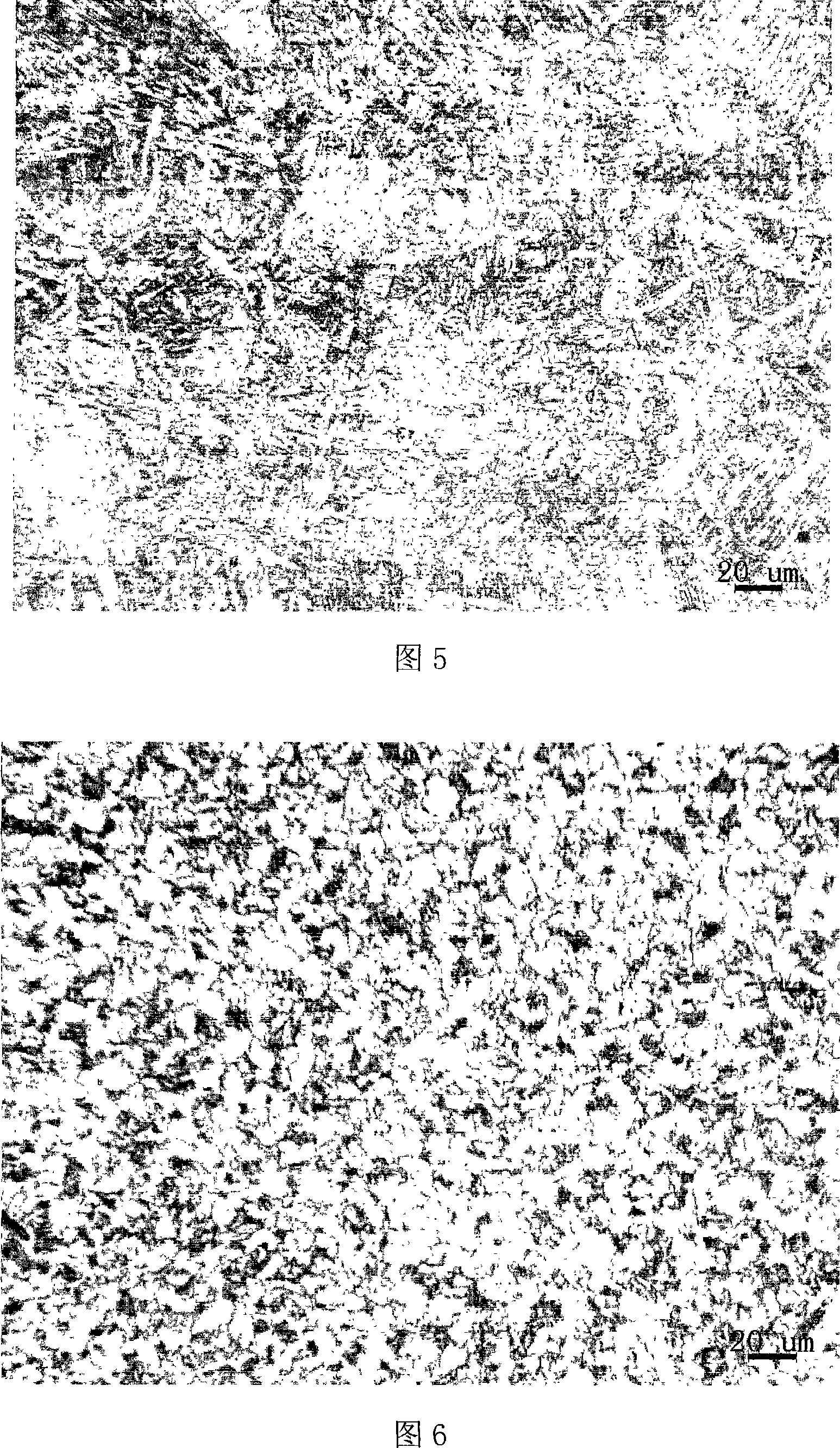

[0022] Embodiments of the present invention are described in conjunction with accompanying drawings 1, 2, 3, 4, 5, 6.

[0023] 1. Deformation heat treatment method 1 to change the microstructure and properties of the weld:

[0024] ① Use an electric heating device to preheat the back of the weld and then keep it warm, so that the temperature of the back of the weld reaches 300°C-500°C:

[0025] ②Adopt the medium frequency induction heating method to heat the front of the weld seam at a heating rate of 30°C / s-100°C / s, so that the overall temperature of the weld seam reaches 700°C-1000°C and then stops;

[0026] ③At a temperature of 750°C-950°C, use rolling rollers to quickly roll the weld along the longitudinal direction of the weld, the rolling speed is 300-500mm / s; the rolling pressure is 4-7t, and the rolling times are 1-2 times. Until the weld reinforcement after rolling is ≤0.4mm. And in the process of rapid welding seam rolling, continue to heat and keep the back of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com